Technical parameters and configuration of 0.25 ton melting furnace

Technical parameters and configuration of 0.25 ton melting furnace

0.25 t smelting furnace power selected power range is generally selected 200-250KW; 1000Hz frequency range; depending on the tonnage, the different process requirements of the melting furnace proper power to achieve the best benefit ratio.

1. 0.25 ton melting furnace configuration and quotation:

|

Medium frequency melting furnace model GWT-0.5/250 |

250KW medium frequency melting furnace Configuration |

200KW Medium frequency melting furnace Configuration |

|

IF melting furnace Rated power |

250KW KGPS IF power supply |

200KW KGPS IF power supply |

|

Frequency melting furnace intake phase voltage |

3*380V |

3*380V |

|

Medium frequency melting furnace rated voltage |

1500V |

1500V |

|

IF melting furnace type rated capacity |

0.25T |

0.25T |

|

IF melting furnace Rated temperature |

1600 ° C |

1600 ° C |

|

With KGPS IF power supply specifications |

KGPS-0.5/250 |

KGPS-0.5/200 |

|

Medium frequency melting furnace configuration list: |

fast KGPS IF power supply |

set |

|

Inverter compensation capacitor cabinet |

set |

|

|

Melting furnace body |

Two sets |

|

|

Melting furnace reducer |

Two sets |

|

|

Water cooled cable |

Two |

|

|

Decidua |

One |

|

|

Manual information |

One |

Second, the classic line 0.25 ton melting furnace configuration instructions:

A, intermediate frequency power supply and electrical parts: intermediate frequency power supply, compensation capacitors and control cabinets.

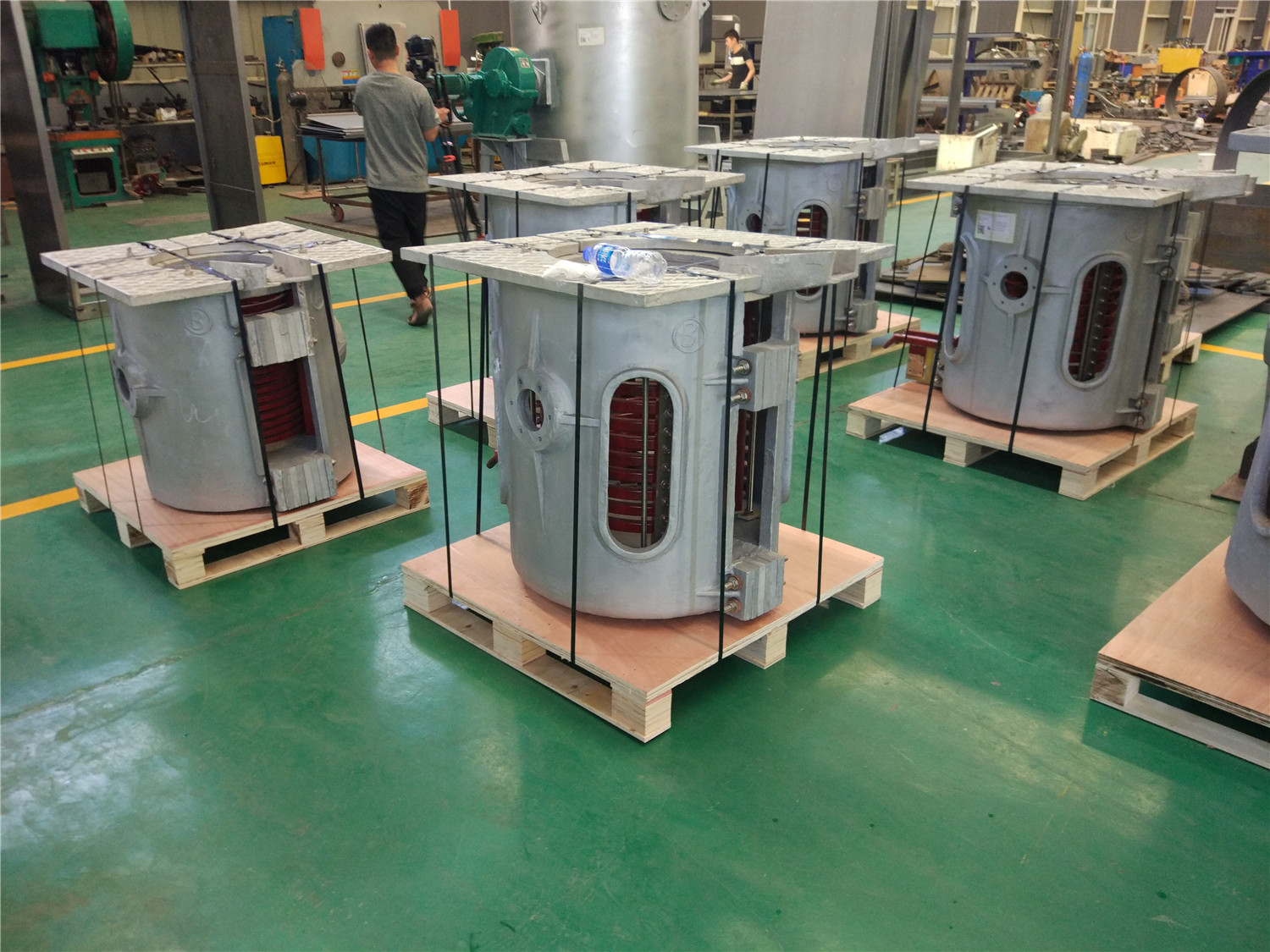

B. Furnace part: equipped with two aluminum shell furnaces, one for production and one for standby; the furnace body includes furnace shell, inductor, crucible, furnace bracket, reducer, water distributor and so on.

C. Connection material: one set of copper to the capacitor to the capacitor cabinet; one set of water-cooled cable (capacitor cabinet to the furnace)

Note: The above configuration is a standard configuration of the typical “one electric two furnaces” form. We can provide configuration solutions that meet the production requirements according to different production process requirements.