The principle of constant power sum and parameter configuration of aluminum shell melting furnace

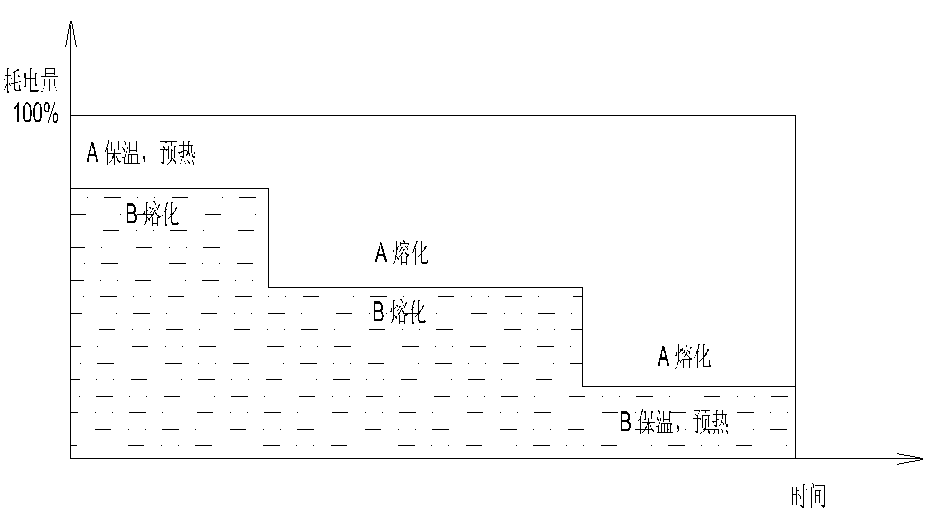

The aluminum shell melting iron furnace can realize simultaneous melting, and can also be smelted in one molten iron furnace . The other molten iron furnace can control the required temperature for casting or heat preservation, or can be smelted and shut down for another one.

Works of aluminum cupola

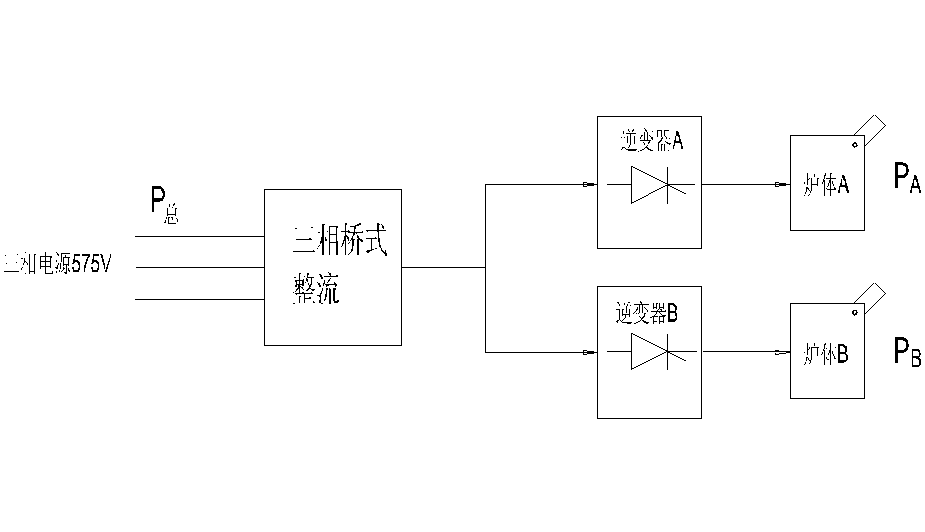

The operation mode adopts aluminum shell melting iron furnace , and the aluminum shell is a set of rectifying power source to drive two sets of inverter devices to operate. It can also be operated by any set of inverter devices separately, and can be supplied to A furnace or B furnace, double power supply aluminum shell function, especially For small and medium production runs high-volume continuous casting, high-power electric Renyiyitai melting operation, the other furnace can heat or cold feed preheat, arbitrarily assigned power demand, using two sets of sum frequency electric power constant ,

That is, total power P total power = PA + PB

The two electric furnaces are continuously alternately melted and insulated for simultaneous operation, so that the power supply can always be operated at full power, thereby increasing the melting productivity of the electric furnace.

The two electric furnaces are continuously alternately melted and insulated for simultaneous operation, so that the power supply can always be operated at full power, thereby increasing the melting productivity of the electric furnace.

When the series inverter power supply is working, the rectification always works under the condition of full conduction. Changing the output power of the inverter circuit is realized by controlling the inverter trigger pulse frequency. And the load current is sinusoidal, so the series inverter power supply will not have high harmonics and seriously pollute the power grid, and the power factor is high. Parallel inverter can not realize the automatic power regulation operation of aluminum shell , because the parallel inverter power supply can only be realized by adjusting the output voltage of the rectifier bridge. When the parallel inverter rectifier bridge works at low voltage, the rectification conduction angle is very small. The power factor of the device will be very low.

When the series inverter power supply is working, the rectification always works under the condition of full conduction. Changing the output power of the inverter circuit is realized by controlling the inverter trigger pulse frequency. And the load current is sinusoidal, so the series inverter power supply will not have high harmonics and seriously pollute the power grid, and the power factor is high. Parallel inverter can not realize the automatic power regulation operation of aluminum shell , because the parallel inverter power supply can only be realized by adjusting the output voltage of the rectifier bridge. When the parallel inverter rectifier bridge works at low voltage, the rectification conduction angle is very small. The power factor of the device will be very low.

And the parallel inverter load current is a square wave, which will seriously pollute the power grid. If the power is adjusted by adjusting the inverter back pressure angle, the power adjustment range is very narrow, so the parallel inverter power supply cannot realize the operation of the aluminum shell .

|

1 t equipment consisting of aluminum cupola |

||||

|

Serial number |

name |

Model (specification) |

Quantity |

Remarks |

|

1 |

Drawing information |

Electronic version |

3 sets |

Equipment and supporting facilities |

|

2 |

IF power cabinet |

1200kw

|

1 set |

With graphic display and temperature detection system, leakage alarm device, main circuit air switch, filter cabinet, rectifier cabinet, copper busbar in the cabinet, rectification and inverter components, etc. |

|

3 |

Compensation capacitor cabinet |

|||

|

4 |

Furnace body |

GW1-600 |

2 sets |

Steel shell furnace body, yoke, induction coil, water-cooled coil, etc. |

|

5 |

Hydraulic station |

Double machine double pump |

1 set |

Oil storage tanks, various valves and dual motors and oil pumps, etc. |

|

6 |

Incubator console |

|

1 set |

Operator console housing and multi-channel manual valve |

|

7 |

Leakage alarm device |

|

2 sets |

|

|

8 |

Water cooled cable |

|

2 sets |

The copper glue line and the hose joint are integrated. |

|

9 |

Model |

|

2 |

|

|

10 |

Connecting cable and copper bar |

Power cabinet to capacitor cabinet |

2 sets |

Large-size double-cooled copper busbar for IF power output |

|

11 |

Water dispenser |

|

2 sets |

|

|

12 |

Low voltage power box |

Combination cabinet water system control |

1 set |

Control cabinet housing for waterway and oil system, internal shunt air switch, relay and thermal protection relay, display instrument and button, etc. |

|

13 |

Metering device |

Energy metering |

1 set |

Provide professional electrical energy measurement test certificate |

|

14 |

Refractory clay |

|

1 ton |

|

|

15 |

Special furnace tool |

|

1 set |

|

|

16 |

Random tool |

|

1 set |

Maintenance and maintenance |

|

17 |

Hot metal temperature measuring device |

|

1 set |

Provide professional temperature test certificate |

Main technical parameters of 1 ton aluminum shell melting iron furnace :

|

1 ton aluminum shell melting iron furnace technical parameters |

||||

|

Serial number |

project |

unit |

1t molten iron furnace parameters |

0.75t molten iron furnace parameters |

|

One |

Electric furnace parameters |

|

|

|

|

1 |

Rated Capacity |

t |

2×1 |

2×0.75 |

|

2 |

Maximum capacity |

t |

2×1.2 |

2×0.9 |

|

3 |

Inductive circle |

Mm |

700 |

620 |

|

4 |

Induction loop height |

Mm |

850 |

750 |

|

5 |

Rated operating temperature |

°C |

1700 |

1700 |

|

6 |

Transformer capacity |

KVA |

1400 |

1000 |

|

7 |

Transformer primary voltage |

KV |

6 |

6 |

|

8 |

Transformer secondary voltage |

V |

380 |

380 |

|

9 |

rated power |

Kw |

1200 |

800 |

|

10 |

Coil voltage |

V |

2000 |

1500 |

|

11 |

Rated operating frequency |

Hz |

500 |

500 |

|

12 |

Power conversion efficiency |

% |

97 |

97 |

|

13 |

Start success rate |

% |

100 |

100 |

|

14 |

Rectifier |

|

6 pulses |

6 pulses |

|

15 |

Inverter |

|

Series inverter |

Series inverter |

|

two |

Comprehensive parameter |

|

|

|

|

1 |

Equipment power factor |

|

≥0.95 |

≥0.95 |

|

2 |

Melting rate (heating up to 1650 °C) |

Min |

80 min |

80 min |

|

3 |

Melting power consumption (temperature up to 1650 °C) |

KW.h/t |

<550 |

<580 |

|

4 |

Working noise |

Db |

≤75 |

≤75 |

|

three |

Hydraulic system |

|

|

|

|

1 |

Hydraulic station capacity |

L |

200 |

200 |

|

2 |

Working pressure |

MPa |

10 |

10 |

|

3 |

Hydraulic medium |

|

46# anti-wear hydraulic oil |

46# anti-wear hydraulic oil |

|

four |

Cooling water system |

|

|

|

|

1 |

flow |

M3/h |

30 |

30 |

|

2 |

Water supply pressure |

MPa |

0.25~0.5 |

0.25~0.5 |

|

3 |

Inlet temperature |

°C |

5~35 |

5~35 |

|

4 |

Effluent temperature |

°C |

35~55 |

35~55 |

|

Fives |

Leakage alarm device |

2 sets |

2 sets |

|