Tubing end thickening technical indicators

1, the outer end of the thick line pipe use environment

1 indoor installation, equipment grounding is good, the color of the grounding wire is obviously different from the control line (the color of the grounding wire is yellow), the cross-sectional area is > 4mm2 , and the grounding resistance is not more than 4 Ω;

2 The altitude should not exceed 1000 meters, otherwise the rated value should be reduced;

3 ambient temperature does not exceed +40 °C, not lower than -10 °C;

4 air relative humidity is not more than 85% ;

5 no severe vibration, no conductive dust, no corrosive gases and explosive gases;

6 installation inclination is not more than 5 degrees;

7 Installed in a well ventilated area.

2 , the tubing end thickening production line grid requirements

1 ) 180KW medium frequency power distribution capacity is not less than 225KVA . 220KW medium frequency power distribution capacity is not less than 275KVA

2 ) The grid voltage should be sinusoidal and the harmonic distortion is no more than 5% .

3 ) The imbalance between three-phase voltages should be less than ± 5%

4 ) The input voltage of the grid is 380V of line voltage AC , and the continuous fluctuation range of the grid voltage does not exceed

± 10% , the grid frequency does not change by more than ± 2% (ie should be between 49~51HZ ).

5 ) The 180KW and 220KW intermediate frequency power supply cable adopts three-phase four-wire system. The incoming cable specification is copper core 240mm2 or 120mm2 × 2 .

3. Main technical indicators of water cooling system

The intermediate frequency induction heating power supply , water-cooled cable, capacitor cabinet, heating furnace body, etc. are cooled by two FL-500 wind - water exchangers.

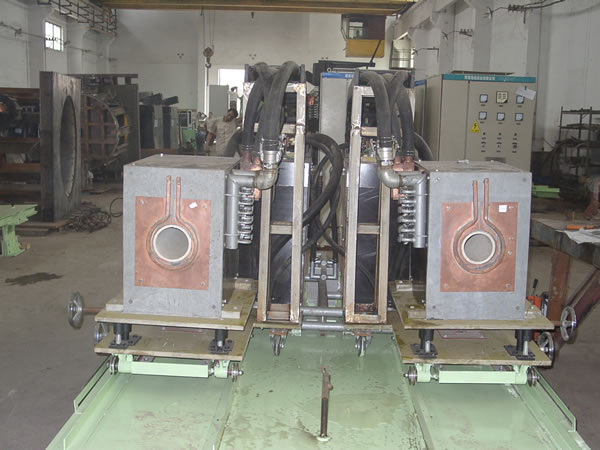

4 , the main technical indicators of the sensor drive system

1 ) Sensor specifications:

No. 1 sensor: inner diameter ф 100mm , suitable for typical tubing specifications ф 60.3~ ф 73.03mm .

No. 2 sensor: inner diameter ф 120mm , suitable for typical tubing specifications ф 88.9mm

2 ) Sensor adjustment:

X- axis direction (left and right): ± 10mm

Z- axis direction (upper and lower): ± 25mm

3) Sensor length: 500mm-650mm

Tubing end thickening technical indicators