The energy loss caused by the intermediate frequency furnace coil is as high as 16%. How to reduce it?

Depending on the installed power density and the melting practice, the thermal efficiency of the induction furnace can exceed 80 %, but usually it is in the range of 60 % to 78 %.

Induction furnaces are normally kept open during the entire melting process where the workers engage in slag skimming and monitoring of the quality of molten bath. However, this leads to significant heat loss and hence special covers or lids need to be installed for reducing heat losses. In particular, reducing the time the lid is kept open while melting, can lead to substantial energy savings.

The theoretical requirement of energy for melting iron is only 340 kWh per ton whereas the actual power required is around 600 kWh. This difference is due to two factors namely (i) inherent in the principle of melting in an induction furnace which include the inefficiency in electrical bus bar losses, eddy current losses, refractory losses, and cooling water losses etc., and (ii) the operational losses which are largely due to unnecessary and excessive holding of liquid steel in the induction furnace.

Induction furnace equipment should be placed with minimum distance between each equipment to reduce wiring losses. To reduce the wiring losses remarkably, it is essential to shorten the distance between furnace body and power factor improving capacitor as very large current flows between them.

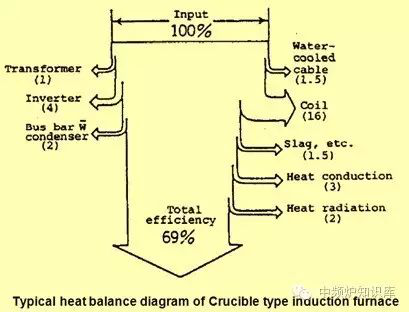

Efficiency of induction furnace is expressed as a total, deducting electrical and heat transfer losses. Typical heat balance diagram of high and medium frequency crucible type induction furnace is shown in Fig. 1. Electrical losses consist in transformer, frequency converter, condenser, wiring, cable, coil, etc. Loss in coil is essential factor, on which the furnace capacity depends. Heat losses in induction furnace consist of conduction loss of heat escaping from furnace wall to coil side, radiation loss of heat released from melt surface, absorption loss in ring hood, slag melting loss, etc. The coils of furnace are water cooled which also results in heat loss. Heat efficiency of high and medium frequency furnaces (60 % – 78 %) is slightly larger than that of low frequency furnace (58 % – 71 %).

Fig 1 Typical heat balance diagram of crucible induction furnac