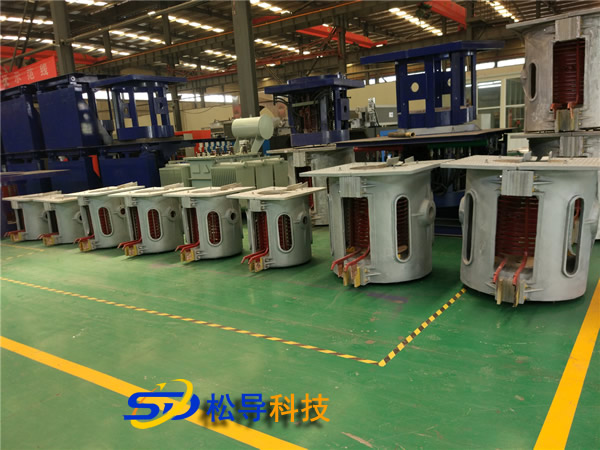

For the special transformer used in the intermediate frequency melting furnace , it is necessary to accurately calculate the parameters on the manufacturing materials. The high-quality high-magnetic, low-loss high-quality silicon steel sheets are used to manufacture the core and the wire, and the copper-iron ratio needs to be determined scientifically. The manufacturing materials ensure that the transformer has low no-load loss and low noise performance. Through the "open source and throttling" method, the heat dissipation of the transformer and the effective control of the current are increased, so that the transformer can be stably and efficiently operated.

Advanced product design, strictly control the heating part of the product and the hottest temperature rise, and leave sufficient temperature rise margin. If necessary, add axial oil passage to the coil, and select the cooling method according to the coil load loss value. The oil flow is distributed to achieve the best cooling effect, and the main temperature rise indicators are at least 5 °C lower than the national standard . The coil and the lead wire are made of copper wire, and the current density is selected to be low.

Special attention is needed: IF melting furnace for selecting transformer requires depends on the size of the furnace, the melting furnace for high intermediate frequency transformer can be provided with a strong overload capability and over-voltage capability, as long as the normal rated load, can be To achieve long-term safe operation, full load long-term safe operation under 110% overvoltage condition (the ambient temperature should be guaranteed at 40 °C ); the intermediate frequency melting furnace dedicated transformer and the motor connected terminals can withstand 1.5 times the rated current, lasting 5S . The product design and manufacture fully consider the load characteristics, and meet the overload requirements from various aspects such as temperature rise, insulation performance and accessory selection.