Induction heating furnace temperature control principle and use method

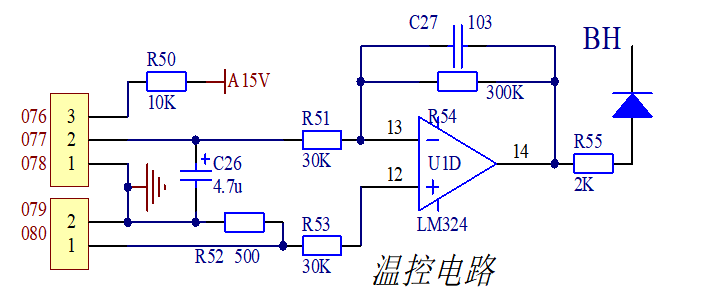

The schematic diagram is shown in the figure. The board includes two parts of temperature control, and the temperature control input signal uses a standard current signal of 0-20 mA. The current signal is taken out by the voltage signal of R52, and then the voltage of the W terminal is calculated. The integrated block U1D amplifies the output. The maximum value of the output voltage has the potential of the W terminal to determine the temperature control circuit. 20mA

The flow signal is compared with the voltage of the external potential of the external potentiometer through R52. The differential pressure between the two is amplified by U1D, and the output voltage changes. The range of change is determined by R54 and R51. The time has been set at about 10 times, the voltage difference between UR52 and UW2 is 0.1V, and the voltage at the output of U1D should be about 1V. In normal operation, the output BH point is low, and after the temperature control is input, the output is high, and the output power of the intermediate frequency power supply is low. To achieve the purpose of temperature control. The temperature is determined by the high or low potential of the W terminal. Under normal circumstances, the high and low W values of the temperature indication can be adjusted accordingly.