The reactive power consumption of the intermediate frequency induction intermediate frequency furnace is mainly caused by the copper loss caused by the induction coil and the water-cooled cable during the operation of the intermediate frequency furnace, and the influence of the unit resistance on the copper loss is very large. Nowadays, in order to reduce the cost of some intermediate frequency furnace production plants, the copper raw materials of the induction coils are mostly made of low-cost copper with high resistance value instead of electrolytic copper No. 1 with low resistance value, resulting in high resistance of induction coil and water wire. The electrical loss per unit time is relatively large.

High-quality high-purity copper tube, the surface color is bright, the resistance is low, the electrical conductivity is good, and the inferior copper is not entirely made of copper material, the copper tube is black and hard, because the impurities can not withstand large current, the electric heating heat is high, the material selection Time should be distinguished.

1, large induction coil, water cable cross-sectional area

Large cross-section of copper wire and copper conductor cable, which not only reduces the heat and voltage loss of the wire, but also increases the reliability of the distribution line and adapts to long-term development, and is also very beneficial from an economic point of view. The investment can be quickly recovered, and users can get more benefits in long-term use.

By increasing the cross-sectional area of the induction coil and water cable, the current density can be greatly reduced, the copper consumption of the power supply line can be reduced, and the operating temperature of the coil and the water cable can be reduced, the probability of scale formation can be reduced, the failure rate can be reduced, and the economy can be saved. Production costs, energy saving, and increase the economic benefits of enterprises.

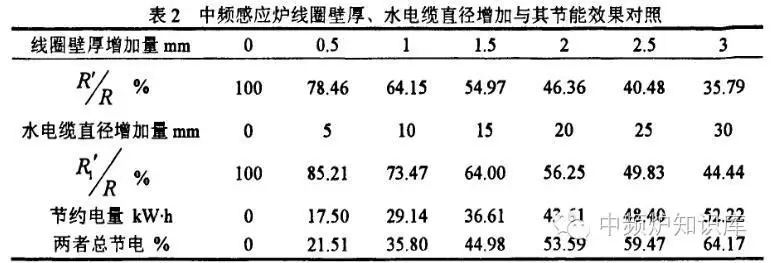

Take 0.5 ton 400 kW intermediate frequency furnace as an example, the induction coil is (outer size) 30x25x2 (mm) rectangular hollow copper tube, the number of turns is 16, the coil diameter is 560mm. The working temperature is 80 °C, the intermediate frequency furnace power factor is 0.1, Calculated that the induction coil itself consumes 80.96 kW at 80 ° C. Similarly, the water cable has a diameter of 60 mm and a length of 2 m. The calculated power consumption at 80 ° C is 0.42 kW. The power consumption at 80 ° C is 8 l.38 kW. As the cross-sectional area of the induction coil and water cable increases, the resistance change and the energy-saving effect of the power supply line are shown in Table 2.

It can be seen from Table 2 that if the wall thickness of the induction coil is increased by 3 mm and the diameter of the water cable is increased by 3 cm, the power consumption per hour of the induction coil and the water cable is 29.16 kW, which is 64.17% higher than the previous power saving, and 52.22 kW per hour. Significantly saves energy.

2, reduce the operating temperature of the induction coil, water cable

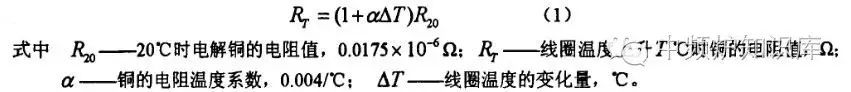

When the induction furnace is smelting, the induction coil and the water cable work up. Because of the temperature coefficient of resistance of copper, the resistivity increases, the resistance becomes larger, and the power consumption increases. The mathematical equation is as follows:

From equation (1), for every 10 °C increase in the operating temperature of the copper coil, its resistance increases by 4% and the power loss increases by 4%. When the operating temperature of the induction coil is reduced from 80 ° C to 50 ° C, the power loss is reduced by 12%, which is a considerable loss for a higher power medium frequency induction furnace. Therefore, an effective cooling system is used to effectively reduce the temperature of the power supply line, and to avoid the formation of a temperature increase -> resistance rise -> temperature rise this vicious cycle, reducing line losses.

3, copper coil surface insulation treatment

The surface insulation treatment of the copper coil can not be ignored. Good insulation treatment can prevent the coil from being ignited. In severe cases, it can even cause the copper tube to break down or burn the bad consequences of the intermediate frequency power supply. Preventing coil ignition itself can also effectively reduce power consumption, shorten smelting time, and improve production efficiency. In comparison with the test results carried out in a 10 ton furnace, after six months of operation, the well insulated coils have a 10% savings in power consumption compared to untreated coils.