Cooling tower (The cooling tower) is used as a circulating coolant water, absorbing heat from a system is discharged to the atmosphere in order to reduce the temperature of the device; which is cooled using the cold and hot water in contact with the air flow generated steam, the volatiles Taking away the heat to achieve the principles of evaporative heat dissipation, convective heat transfer and radiation heat transfer to dissipate the waste heat generated in the industrial or refrigeration air-conditioning to reduce the water temperature, to ensure the normal operation of the system, the device is generally barrel-shaped, so Named the cooling tower.

Introduction

The cooling tower is a comprehensive product integrating aerodynamics, thermodynamics, fluidics, chemistry, biochemistry, materials science, static and dynamic structural mechanics, and processing technology. Water quality is a multivariate function, cooling is a multi-factor, multivariate and multi-effect synthesis process [1] .

1. There must be a certain amount of surplus energy (20%-25%) in the cooling tower circulating water system . When running, this energy is concentrated at a certain valve, and the energy is lost in a long time. The external turbine is converted into high-efficiency mechanical energy by using these “ rich energy ” , so that the cooling tower fan motor can be replaced 100% for power saving purposes.

2. The key to how the external turbine can achieve the motor drive efficiency is to understand the surplus energy in the design of the cooling tower circulating water system. At the same time, the turbine impeller design is also the key. The composition of the surplus energy is mainly composed of the following six parts:

1 ) the margin value that must be considered when designing the circulating water system;

2 ) potential energy utilization of heat exchange equipment;

3 ) the self-regulating ability of the turbine;

4 ) kinetic energy conversion efficiency of the circulating water system;

5 ) The energy consumed by the valve when the valve is not in place.

6 ) Low flow meets system requirements by combining and re-splitting methods.

3. Cooling tower old tower energy-saving renovation

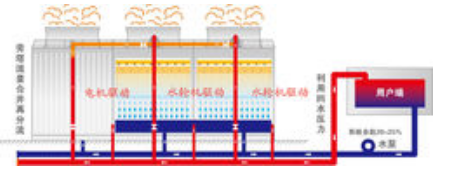

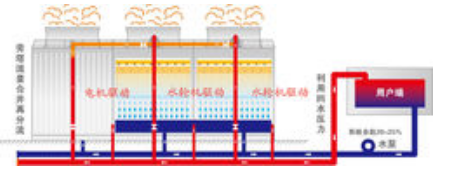

Cooling tower between the heat exchange device and is driven by a circulating pump, external pressure turbine using return energy to convert water turbine driven fan for power driven, generally in accordance with the cooling tower to do three energy-saving, the actual volume flow rate is too large design 60 About % , taking into account changes in production demand, the energy-saving transformation method is: two towers are driven by a turbine, and one tower is motor-driven for standby in summer time.

4. Cooling tower new tower design

The focus of the external turbine is on the return pressure or return flow to meet the function of the turbine to drive the fan, the law of conservation of energy - how much backflow or pressure conversion = how much fan speed. The external turbine speed is increased or decreased according to the increase or decrease of the system flow. The system has three external turbine cooling towers and three towers for the turbine outlet pipe. The bypass valve is used to adjust the flow and facilitate maintenance.

Schematic diagram of three cooling towers:

product structure

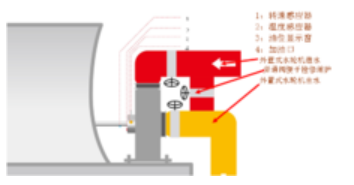

The external turbine cooling tower, as its name implies, is mainly equipped with a turbine installed outside the cooling tower air duct. The main components of the external turbine are 304# stainless steel impeller, 316L stainless steel main shaft, and the volute main engine is made of carbon steel. The impeller is an important component of energy conversion. The circulating water enters the impeller and generates a swirling flow when the impeller is guided, which further improves the energy conversion efficiency of the impeller. The turbine foundation is 900*900 upper and lower steel plates with stud bolts to adjust the position (easy maintenance and repair). The weight design of the turbine is similarly matched with the weight of the conventional motor and the soft connection of the gearbox transmission in the air cylinder.

The external turbine of the cooling tower has no space limitation due to the position of the motor installed outside the air duct of the cooling tower. The diameter, number, shape and angle of the external turbine impeller can be enlarged according to the actual situation of the customer, and the torque can be increased to improve the conversion efficiency. Different flow and pressure system designs achieve the most perfect transmission conversion ratio, and the cooling tower fan speed is greater than or equal to the original motor driven fan speed. The shape of the external turbine snail uses a bionic snail-like effect to reduce the impact and vibration rate of the circulating water.