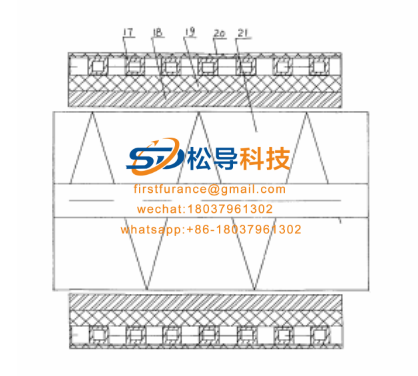

The inner spiral rotary induction heating furnace includes a spiral drum (21), and a heat insulation layer (18) is provided around the spiral drum (21), and a heat insulation layer (19) and a heat insulation layer (19) are provided outside the heat insulation layer (18). There is an intermediate frequency induction coil (17) outside, and an insulation case (20) is wrapped around the intermediate frequency induction coil (17). An intermediate frequency induction quenching and tempering production line equipped with an internal spiral rotary intermediate frequency induction heating furnace. An internal spiral rotary induction heating furnace (6) is installed between a spiral hot air drying furnace (5) and a quenching tank (7). An internal spiral rotary induction heating furnace (6) is also connected between the spiral hot air drying furnace (12) and the rotary cooling furnace (15). The utility model is energy-saving, time-saving, and does not require an oven. The utility model has the advantages of long service life and low maintenance cost, fast temperature rise and cooling, and short maintenance time. Induction heat treatment can improve the strength and life of parts.

http://www.songdaokeji.com/plus/list.php?tid=42