At present, the refractory brick in the induction melting furnace in the prior art has a complicated structure, is inconvenient to disassemble and maintain, and has poor interchangeability.

Poor moisture resistance and temperature resistance. The purpose of the transformation is to solve the deficiencies in the prior art, and to provide a temperature-resistant refractory brick for an induction melting furnace with a simple structure and convenient operation.

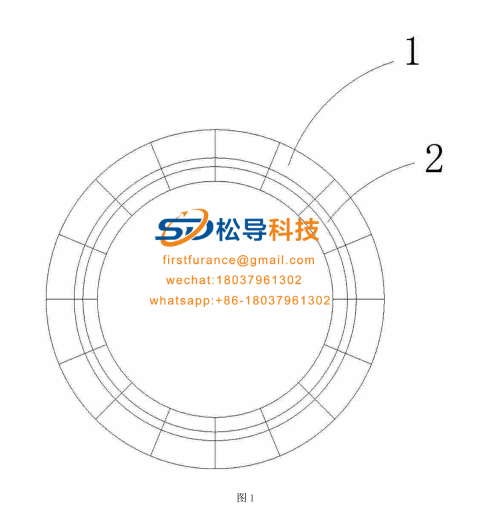

Mainly through transformation, the uniformly distributed refractory bricks are enclosed in a circle, and the refractory bricks are provided with cutout ring grooves, and the cutout ring grooves are annular. This structure is easy to install, has high interchangeability and strong moisture absorption and temperature resistance. Preferably, the refractory brick is fan-shaped, and the interruption ring groove is an arc groove. Therefore, the temperature-resistant refractory brick for an induction melting furnace of the utility model has a simple structure, convenient installation, strong versatility, and strong temperature resistance.

Figure 1 is a structural schematic diagram of the transformation of a temperature-resistant refractory brick of an induction melting furnace;

Concrete transformation method

The refractory refractory bricks of the transformed induction melting furnace include uniformly distributed refractory bricks enclosed in a circle, and the refractory bricks are provided with cutout ring grooves.

http://www.songdaokeji.com/plus/list.php?tid=22

http://www.songdaokeji.com