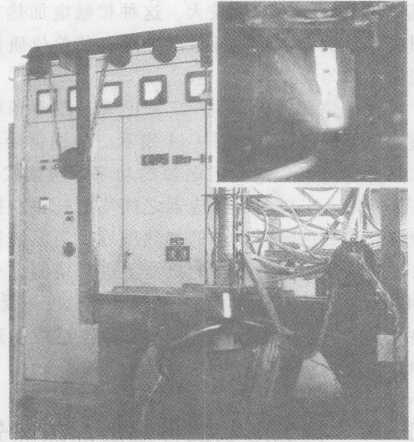

Chain induction heating furnace quenching

After the chain is bent into shape and welded, the chain links are connected together one by one, and then need to undergo quenching and tempering heat treatment. In the past, chain quenching and tempering heat treatment was heated in a resistance furnace, followed by quenching and tempering. Now some chain manufacturers have adopted induction heating furnaces for chain quenching and tempering heat treatment. The picture shows the induction heating furnace device for chain quenching. The power supply is 100kW and the current frequency is 8000Hz. The induction coil is spiral and installed vertically on the quenching equipment. The chain enters from the top of the inductor, moves vertically downwards, after passing through the inductor, reaches the required heating temperature, enters the water tank under the inductor for quenching, and then undergoes tempering. Although the shape of the chain is special, its heating temperature can meet the process requirements after induction heating.