How does one-time induction heating furnace quenching of large-diameter crown gears work?

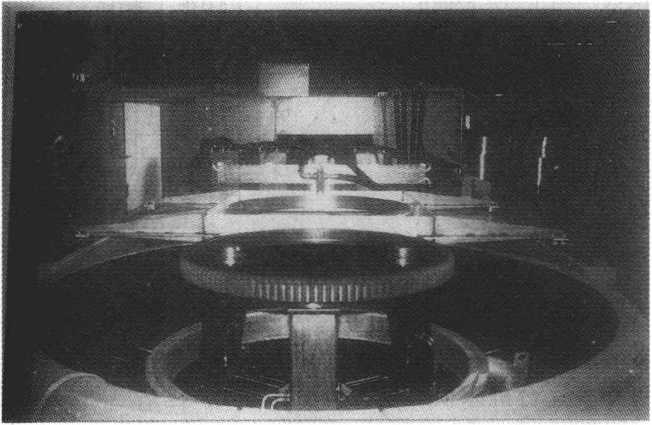

The large-diameter crown gear is quenched in an induction heating furnace at one time, and the processed gear diameter is 500 ~ 1600mm, the modulus is 6 ~ 14mm, and the hardening depth is 2 ~ 3mm below the gear root circle. Crown gear induction heating furnace and quenching device are shown in Figure 8-42.

Figure 8-42 Crown gear induction heating furnace and quenching device

The solid-state power supply has two levels of frequency and power, namely 1600kW/4kHz and 1200kW/8kHz. The selection of gear induction heating frequency depends on the modulus. After the large gear is induction heated, it falls into the quenching spray with a flow rate of 8000L/min, and the quenching solution contains additives. After the gear is quenched, return to the induction heating furnace to perform stress relief tempering. The typical production capacity, taking a gear with a diameter of lm and a module of 8mm as an example, is 10 pieces/h.