Selection of Process Parameters of Induction Heating Furnace for Tempering Treatment of Elbows

The tempering treatment of the elbow is completely carried out by the induction heating furnace process. The selection of parameters such as tempering temperature, holding time and tempering cooling method are all based on obtaining the best comprehensive performance.

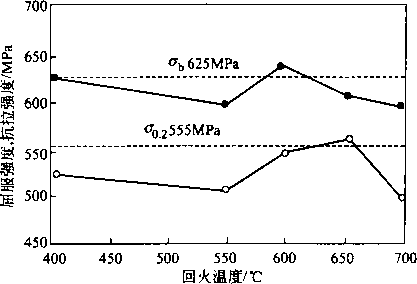

(1) The relationship between tempering temperature and strength Figure 10-5 shows the relationship between tempering temperature and yield strength and tensile strength. The tempering holding time is 60min. From Figure 10-5

The curve relationship shows that when the tempering temperature is between 600°C and 650°C, the maximum yield strength value is obtained, and it decreases when the temperature exceeds 650°C. The tensile strength reaches the highest value when tempered at 600°C, and begins to decrease when it exceeds 600°C. According to the relationship between strength and tempering temperature, in order to make the yield strength and tensile strength meet the standard requirements, the tempering temperature should be selected at 600~650℃.

strength

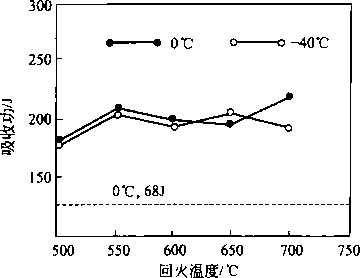

(3) Tempering holding time and tempering cooling mode of induction heating furnace can be seen from the relationship curve of tempering temperature and intensity, the carbide phase has been fully analyzed during tempering and the intensity reached the peak value (600~650°C) After the temperature exceeds this temperature, the carbides begin to coarsen and the strength begins to decrease. This phenomenon reflects that the 60min tempering holding time is sufficient. From the relationship curve between tempering temperature and low-temperature impact toughness of steel, it can be seen that this steel grade does not have low-temperature brittleness and tempering brittleness. Therefore, air cooling can be used after tempering.