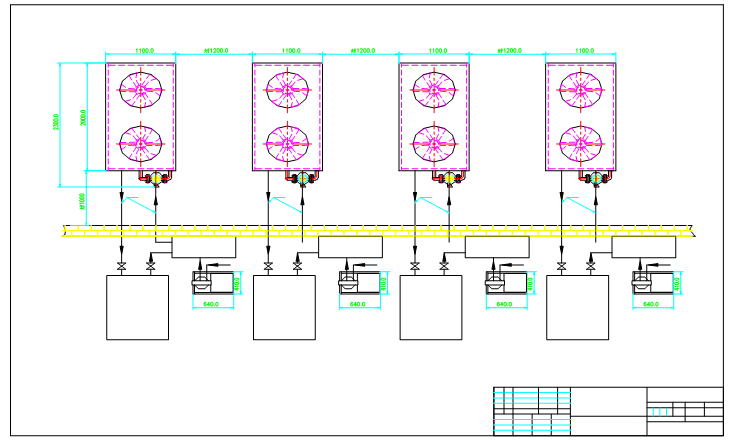

Basic configuration of steel tube induction heating furnace

Steel tube induction heating furnace configuration

The steel pipe is heated online before sizing. It adopts a combined straight-through induction furnace. There are three combined sections. Each combined section includes an intermediate frequency power supply, a capacitor cabinet and two inductors. There is a transport roller table between the inductors to make The steel pipe runs at a certain speed. The system uses three 12-pulse rectifier transformers for power supply. The whole set of equipment is controlled by a set of computer control system to meet the steel pipe heating requirements. The 3 power supply cooling systems use 3 wind water coolers. Attachment: (See the figure for the configuration of the water-cooling equipment of the steel pipe on-line heating power supply capacitor) The working pressure is 0.2~0.3Mpa; the working flow is 20M3/h

The calculated value is as follows:

It is known that the intermediate frequency power supply is 1500KW, the heating coefficient per kilowatt of the power supply is 0.09, the heating coefficient per kilowatt of the capacitor is 0.036, the conversion value of the function and the heat unit is 860 kcal/h, the average temperature difference between the inlet and outlet water is 8 ℃, and the specific heat capacity of water is 1,000. Cal/kg·℃×1000, the density of water is 1000kg/M3.

Calorific value: 1500×(0.09+0.036)=189KW

189×860=162540 kcal/h

135450÷8÷1000=20M3/h

Take 1.1~1.25 safety factor: 20×1.1=22M3/h

The amount of heat taken away by the pump is: 22×8×1000=16700 kcal/h

Conclusion: 176000 kcal/h>162540 kcal/h, so 25M3/h of 1500KW power supply cooling water is sufficient for the induction heating furnace cooling. The sensor cooling water adopts pure circulating water: working flow 50T/h, working pressure 0.2~0.3Mpa, known power supply 1500KW, sensor heating coefficient per kilowatt is 0.3, conversion value of function and heat unit is 860 kcal/h, enter , The average temperature difference of the outlet water is 8℃, the specific heat capacity of water is 1 kcal/kg·℃×1000, and the density of water is 1 000kg/M3.

Then the calorific value of the sensor is: 1500×0.3=450KW

450×860=387000 kcal/h

Basis for pump selection: 387000÷8÷1000≈48.4M3/h

Take 1.25 safety factor: 48.4×1.1=53.21M3/h

The heat taken away by the pump is: 53.21×8×1000=425700 kcal/h

Conclusion: 425,700 kcal/h>387,000 kcal/h, so 50M3/h of cooling water for 1500KW inductors meets the requirements of equipment cooling.