Teach you how to use induction melting furnace and AOD furnace to produce stainless steel

Traditional stainless steel smelting mostly uses electric arc furnace return oxygen blowing method. With the development of the refining method outside the furnace, the electric arc furnace has increasingly become a melting device, and the alloying and refining process of molten steel is completed in the AOD or VOD refining equipment. In addition to these two main stainless steel smelting methods, ASEA-SKF, RH-OB, etc. can also be used as stainless steel refining equipment, and the primary furnace can also be an oxygen converter or an induction melting furnace. Stainless steel is the most suitable steel for high alloy steels to be cast into billets with slab continuous casters. Nowadays, the annual production scale of professional stainless steel plate production plants can reach 800,000-1 million t/a, using an electric arc furnace-refining furnace -Slab caster-hot rolling mill production line can be completed.

In order to maintain the continuity of the production process, the capacity of the electric arc furnace should be above 80t, and the smelting cycle should not be greater than 60 mino, otherwise the continuous casting of multiple furnaces cannot be maintained, and the production efficiency is greatly reduced. In addition to the large demand for stainless steel plates, there is also a certain demand for stainless steel pipes, wires and castings, and the production scale is smaller than that of plates. When scrap steel is used as the main raw material, either electric arc furnace or induction melting furnace can be used as the primary smelting furnace, with AOD or VOD smelting high-quality molten steel. When producing castings, it can be cast into finished products. When producing rolled products, it needs to be cast into ingots or billets are continuously cast into billets. To ensure continuous production, the smelting cycle of the smelting furnace should be 55~65min.

This case mainly introduces the situation of induction melting furnace used to melt scrap steel and primary smelting (with gold and carbon) and AOD furnace to smelt stainless steel. At present, there are 25t induction melting furnace and 30t AOD furnace in China to produce stainless steel. The matching AOD furnace produces stainless steel production line.

1. The process flow of induction melting furnace and AOD furnace for producing stainless steel

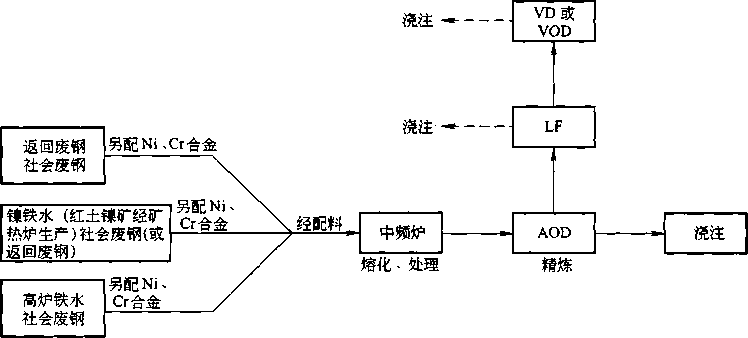

The process flow of the induction melting furnace and the AOD furnace for producing stainless steel is shown in the figure.

MFF-AOD process flow

When using induction melting furnace and AOD furnace to produce stainless steel, the metal materials used can be determined according to the specific supply conditions of the manufacturer, as shown in Figure 4-27, indicate (1) or (2) or (3) three types of metal materials. After the prepared metal material is added to the induction melting furnace and melted and processed, the initial molten steel can be mixed into the AOD furnace. After refining, it can be refined into different grades of stainless steel and can be directly poured into ingots (continuous casting billets) or castings . According to the requirements of the variety and quality, the stainless steel refined by AOD can be processed by LF furnace and then poured or further processed by VD or VOD furnace for casting.

2. Key points of smelting process

A. Requirements for furnace charge when matching metal materials

When mixing metal materials, such as smelting 304, 321 stainless steel, the stainless steel charge into the induction melting furnace should have certain requirements for its chemical composition: C is 1.2% ~ 1.5%, Si is not more than 0.30%, Mn residue, P, S are more The lower the better, the general requirement is not more than 0.03%, the Cr is 18% -19%, and the range is 7.5% ~8.5%.

The 1.2% ~ 1.5% of C required for C is not absolute. In principle, the C content of the metal material should not be too low, otherwise the heat source is insufficient and the blowing time is too short. Process requirements for P de-S and alloying adjustment composition. On the contrary, if the C content is too high, the high-carbon metal material melted by the induction melting furnace enters the AOD furnace. Although the heat source is sufficient and even the coolant is added, as the smelting time is too long, the productivity decreases and the furnace age decreases. Moreover, the excessively long smelting time cannot guarantee the continuous production of continuous casting.

Since the induction melting furnace melts Ni and FeCr alloys with less oxidation loss and convenient control, the upper limit of the Ni and Cr specifications of the stainless steel can be matched during the batching.

It is desirable for the Si content to be low when mixing Si, which is more advantageous for the AOD furnace, which can reduce the amount of slag, which not only reduces the loss of the alloy, but also increases the life of the AOD furnace.

The AOD furnace has the ability to remove P and S, but although the high basicity reduction slag can effectively desulfurize, the dephosphorization capacity is limited, and the desulfurization capacity is also limited. Therefore, the P and S of the primary molten steel into the AOD furnace should be as low as possible . Because the induction melting furnace does not have the ability to remove P and S. This inevitably requires that the lower the metal material P and S when entering the induction melting furnace, the better.

There is no requirement for Mn in the raw material when mixing metal materials, depending on the residual situation in the scrap steel.

B Induction melting furnace melting and processing

When the induction melting furnace melts the metal material, it not only has the above requirements for the chemical composition of the charge, but also has certain requirements for the temperature of the molten steel after melting. Generally, N1650Y is required. In addition, it should be noted that the connection between the melting treatment time and the AOD refining time should not cause a disconnection, forming an induction melting furnace waiting for the AOD furnace or AOD furnace waiting for the induction melting furnace, which will not only reduce productivity, but also increase energy consumption and affect the life of the furnace.

Special attention should be paid when the induction melting furnace is used to melt and return scrap steel. As the amount of return steel increases, it will inevitably lead to an increase in harmful trace elements such as lead, xenon, fetters, tin, etc., especially Pb. Because Pb-containing easy-cutting stainless steel is difficult to separate from other steel grades, the Pb content in the finished steel increases, which affects the hot workability of the product.