Comparative analysis on the application of mica board and epoxy glass fiber cloth laminate

Mica board and epoxy glass fiber cloth laminate are often used in daily life. Today, we will make a comparative analysis of the application of mica board and epoxy glass fiber cloth laminate. The first is the mica board:

The mica board has excellent bending strength and processing performance. The mica board has high bending strength and excellent toughness. The mica board can be processed in various shapes without delamination. Excellent environmental performance, the mica board does not contain asbestos, has less smoke and odor when heated, and is even smokeless and tasteless.

Among them, HP-5 hard mica board is a high-strength slab mica plate-like material. The mica board can still maintain its original performance under high temperature conditions. It is widely used in the following fields:

Household appliances: electric irons, hair dryers, toasters, coffee makers, microwave ovens, electric heaters, etc.;

Metallurgical and chemical industry: industrial frequency furnaces, intermediate frequency furnaces, electric arc furnaces, injection molding machines, etc. in the metallurgical industry.

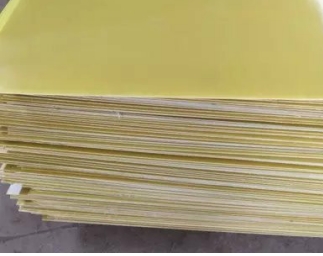

Epoxy glass fiber cloth laminate: Glass fiber cloth is made by heating and pressing with epoxy resin. It has high mechanical performance at medium temperature and stable electrical performance at high temperature. It is suitable for high-insulation structural parts for machinery, electrical appliances and electronics, with high mechanical and dielectric properties, good heat resistance and moisture resistance. Heat resistance grade F (155 degrees). To

The reaction between the epoxy resin and the curing agent used is carried out by direct addition reaction or ring-opening polymerization reaction of epoxy groups in the resin molecule, and no water or other volatile by-products are released. Compared with unsaturated polyester resins and phenolic resins, they show very low shrinkage during curing. The cured epoxy resin system has excellent mechanical properties. But the overall performance is not as good as the mica board.

Application characteristics

1. Various forms. Various resins, curing agents, and modifier systems can almost adapt to the requirements of various applications on the form, and the range can be from very low viscosity to high melting point solids.

2. Convenient curing. Choose a variety of different curing agents, the epoxy resin system can almost be cured in the temperature range of 0 ~ 180 ℃.

3. Strong adhesion. The inherent polar hydroxyl groups and ether bonds in the molecular chain of epoxy resins make it highly adhesive to various substances. The shrinkage of epoxy resin is low when curing, and the internal stress generated is small, which also helps to improve the adhesion strength.

Specification thickness: 0.5~100mm

Conventional specifications: 1000mm*2000mm

Color: yellow, water blue, black

The hardness of the epoxy glass fiber cloth laminate is greater than that of the mica board, but the temperature difference is somewhat different.