Selection method of furnace body for round steel induction heating furnace

A. Furnace structure

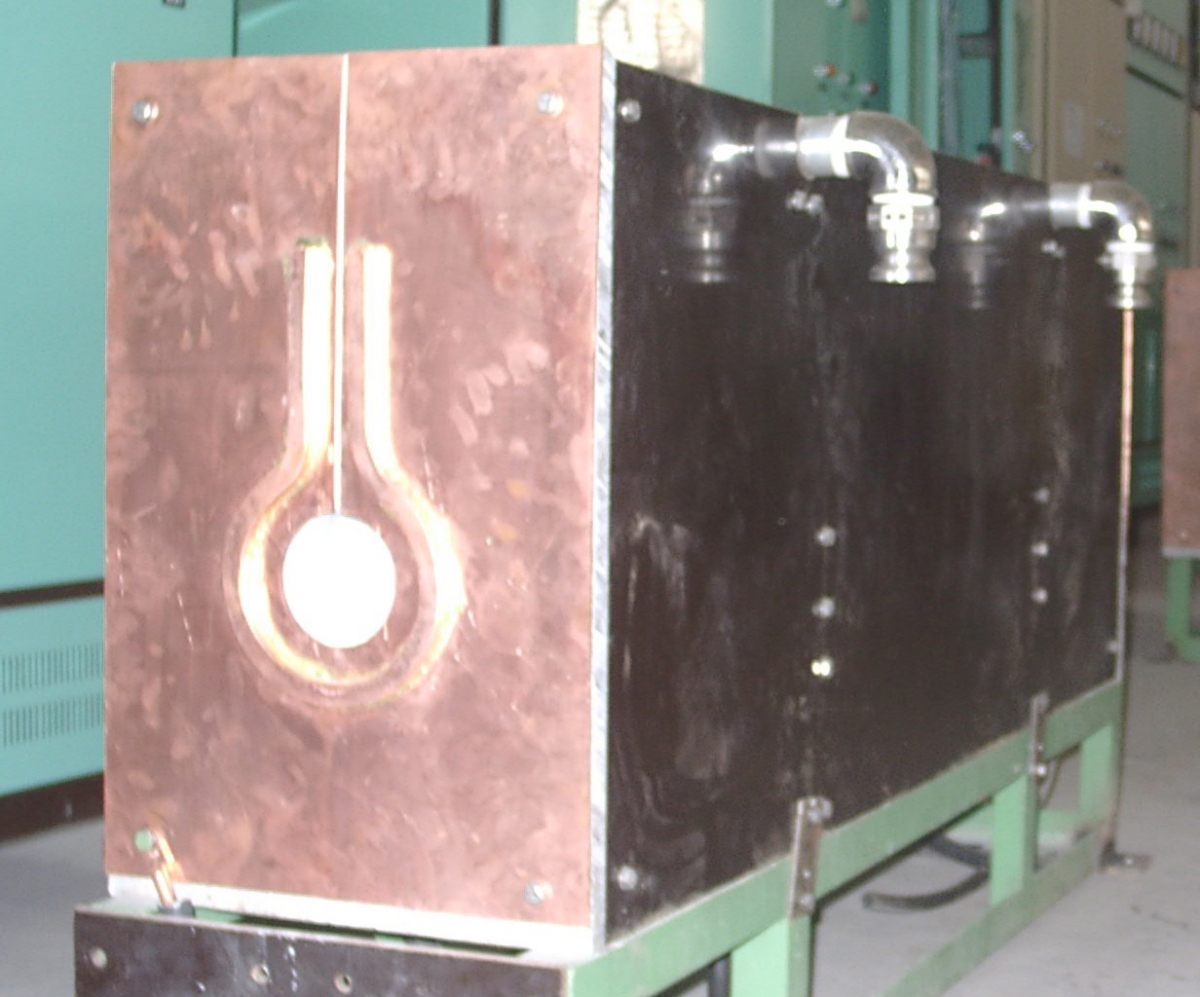

For different heated workpieces, different heating furnaces should be replaced when heating. In order to facilitate the replacement and reduce the workload when replacing the furnace body, the heating furnace of our company is designed as an integral quick-change type (see picture). When the furnace body is changed for different heating workpieces, rapid replacement can be realized.

The water connection is a quick connector. For reliable electrical connection and rapid replacement, a large stainless steel bolt connection method is adopted. When replacing, only need to loosen this bolt and open the water joint locking device.

B. Water quick-change joint: In order to facilitate the replacement of the furnace body, a quick-change joint is used in the design of the pipe joint, as shown in the figure below

Quick coupling

Its material is 316 stainless steel. It is mainly composed of threaded connector, hose connector, clasp wrench, sealing gasket, etc. The biggest feature of this kind of quick-change joint is: the threaded connection piece and the hose connection piece can be mutually matched, the clamping wrench is easy to operate, and the sealing performance is good.

C. Furnace lining: Furnace lining adopts silicon carbide or integral knotting method, and the service temperature is above 1450℃. It has good insulation, heat insulation, chilling and heat resistance and impact resistance.

D. Water-cooled rail for induction furnace: A water-cooled rail is installed on the lining of the induction furnace, and the heated workpiece runs on the rail. In order to improve the life of the water-cooled track, our company has built up a layer of wear-resistant material on the water-cooled track, which greatly improves the life of the water-cooled track.