Correct selection of induction melting power supply and induction melting furnace configuration method

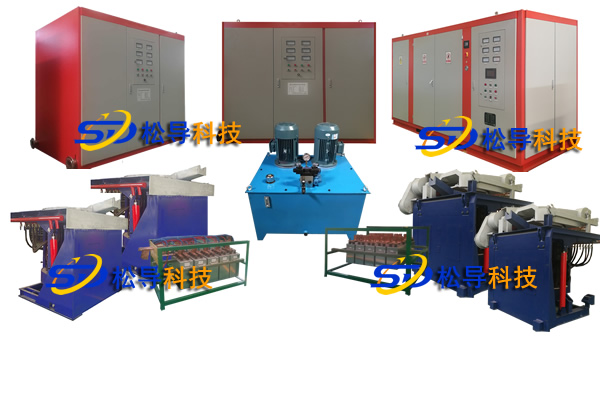

To accommodate different casting necessary, in order to sufficiently increase the frequency power supply power utilization factor, a variety of medium frequency power induction melting furnace configuration mode,IF power supply and induction melting furnace configuration

1.Single frequency power supply with a single furnace:

It is simple and reliable, and is suitable for occasions where the molten metal in the electric furnace is quickly emptied after melting, and then re-feeding and melting, or when the operation is infrequent.

Suitable only for small capacity and lower power electric furnaces.The operating power utilization factor (K2 value) is low.

2.Single frequency power supply with two furnace(switching by switch):One electric furnace is melted, and the other is poured or repaired or built.

When making a small-capacity multiple pouring operation, the intermediate frequency power supply that supplies power to the melting operation electric furnace can be switched to the electric furnace of the pouring operation for a short time to quickly heat up to compensate for the drop of the pouring temperature. The alternating operation of the two electric furnaces (melting and pouring, feeding operation) ensures continuous supply of high-temperature qualified molten metal to the casting line.

The operating power utilization factor (K2 value) is high.

3.Two frequency intermediate frequency power supplies (meltedintermediate frequency power supply and insulated intermediate frequency power supply ) with two furnaces (switched by switch):The configuration scheme adopts a full-bridge parallel inverter solid medium frequency power supply , and two electric furnaces are alternately connected with the melting intermediate frequency power supply and the insulated intermediate frequency power supply through the switch .

The IF power switching is completed by means of an electric switch, which is easy to operate and has high operational reliability.

The downside is that the insulated intermediate frequency power supply needs to operate at a slightly higher frequency than the molten intermediate frequency power supply in order to match the same induction coil . As a result, the agitation effect during the alloying treatment may be small, and it is sometimes necessary to switch the molten intermediate frequency power source for a short time to enhance the alloying process.

The operating power utilization factor (K2 value) is high.

4.Single dual supply medium frequency power supply with two furnaces:Each electric furnace can select the appropriate power according to the respective working conditions;No mechanical switch, high reliability;The operating power utilization factor (K2 value) is high, theoretically up to 1.00, thereby greatly increasing the productivity of the electric furnace;It continues to operate at a constant power throughout the melting process, so the power frequency power supply utilization factor (K1 values) high;Only a single frequency power supply transformer and a cooling device, compared with the embodiment 3, the total installed capacity of the small main transformer, space is also small.