Site Bulletin

Iron induction furnace

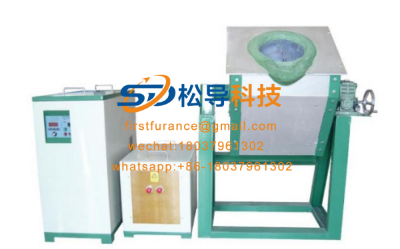

Aluminum melting furnace

Copper melting furnace

Small steel melting furnace

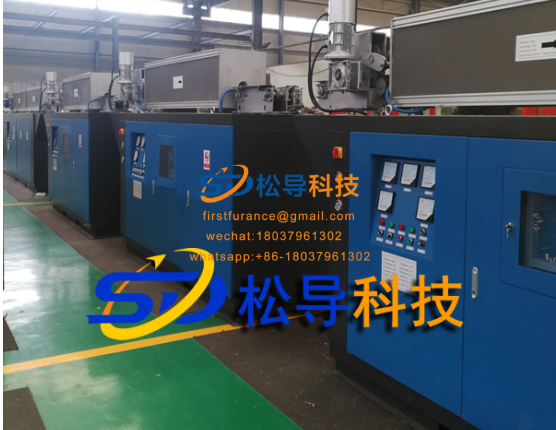

Small induction melting furnace

Induction iron furnace

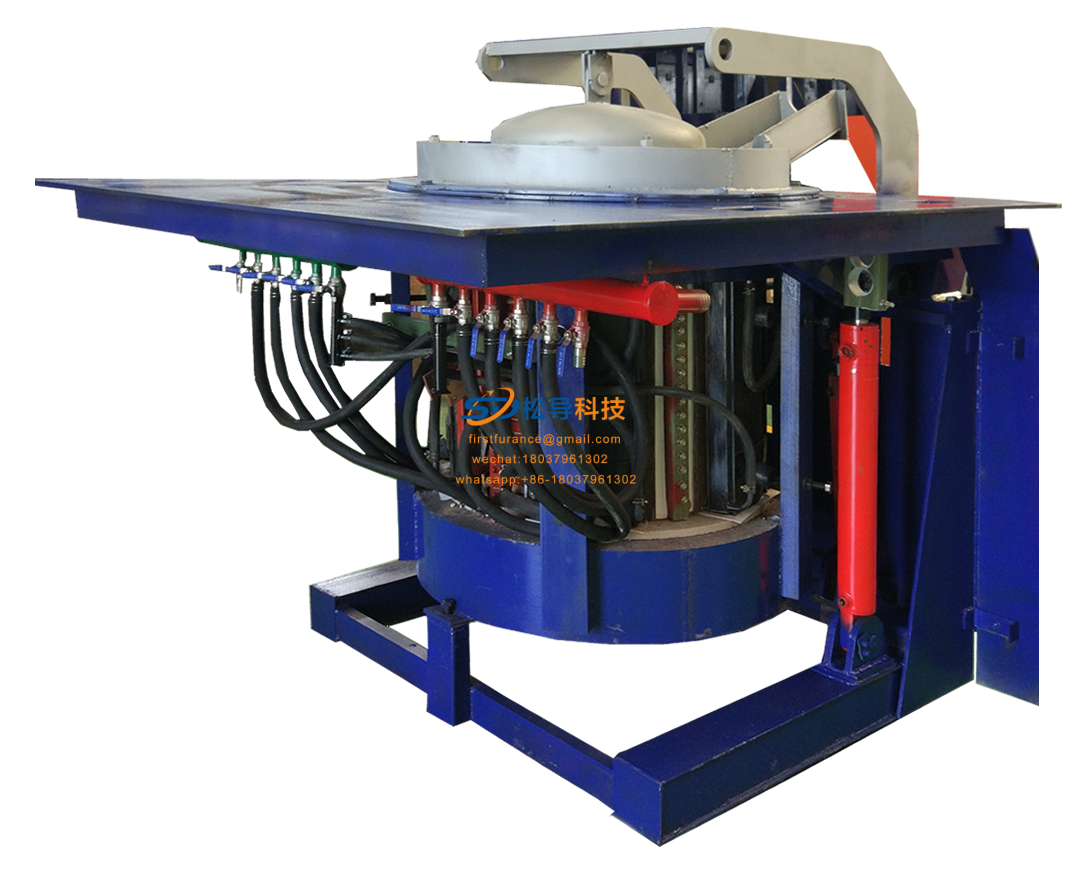

3T intermediate frequency iron melting f

0.25T Intermediate Frequency Furnace

0.5T Intermediate Frequency Furnace

Medium Frequency Furnace

2T Induction Melting Furnace

1T Induction Melting Furnace

500kg Induction Melting Furnace

250kg Induction Melting Furnace

Induction Melting Furnace

3 T Induction Melting Furnace

5T Induction Melting Furnace

1T One Belt Two Intermediate Frequency F

5T One Belt Two Intermediate Frequency F

3T One Belt Two Intermediate Frequency F

2T One Belt Two Intermediate Frequency F

5T Parallel Intermediate Frequency Furna

5T Intermediate Frequency Furnace

5T Series Intermediate Frequency Furnace

3T Series Intermediate Frequency Furnace

2T Series Intermediate Frequency Furnace

1T Series Intermediate Frequency Furnace

0.5T Series Intermediate Frequency Furna

0.25T Series Intermediate Frequency Furn

1T Parallel Intermediate Frequency Furna

2T Parallel Intermediate Frequency Furna

0.5T Parallel Intermediate Frequency Fur

0.25T Parallel Intermediate Frequency Fu

Parallel Intermediate Frequency Furnace

3T Intermediate Frequency Furnace

2 T Intermediate Frequency Furnace

1T Intermediate Frequency Furnace

0.25T Intermediate Frequency Furnace

0.5T Intermediate Frequency Furnace

Medium Frequency Furnace

One Belt Two Intermediate Frequency Furn

series intermediate frequency furnace

Steel Shell Intermediate Frequency Furna

3T Parallel Intermediate Frequency Furna

Aluminum Shell Medium Frequency Furnace

Steel pipe medium frequency quenching eq

Round steel medium frequency forging fur

Surface quenching and single tooth surfa

Drill pipe medium frequency conditioning

Medium frequency forging furnace

Φ25 × 80 round steel induction heating f

Φ70×100 round steel induction heating fu

KGPS300KW/1.5 round steel medium frequen

φ50 ×100 round steel heating furnace

Metal casting furnace

Copper casting furnace

Gold melting furnace

Silver melting furnace

50kg metal powder atomization special me

50KG medium frequency copper melting fur

Contact Us

Tel: 18037961302

Tel: 18037961302Sales hot line ( 24 hours service): 18037961302

E-Mail: firstfurnace@gmail.com

whatsapp:+8618037961302

Adress: Luoxin Industrial Park, Luoyang, HenanProducts

-

Iron induction furnace

Iron induction furnace -

Aluminum melting furnace

Aluminum melting furnace -

Copper melting furnace

Copper melting furnace -

Small steel melting furnace

Small steel melting furnace -

Small induction melting furnace

Small induction melting furnace -

Induction iron furnace

Induction iron furnace -

3T intermediate frequency iron melting f

3T intermediate frequency iron melting f -

0.25T Intermediate Frequency Furnace

0.25T Intermediate Frequency Furnace -

0.5T Intermediate Frequency Furnace

0.5T Intermediate Frequency Furnace -

Medium Frequency Furnace

Medium Frequency Furnace -

2T Induction Melting Furnace

2T Induction Melting Furnace -

1T Induction Melting Furnace

1T Induction Melting Furnace -

500kg Induction Melting Furnace

500kg Induction Melting Furnace -

250kg Induction Melting Furnace

250kg Induction Melting Furnace -

Induction Melting Furnace

Induction Melting Furnace -

3 T Induction Melting Furnace

3 T Induction Melting Furnace

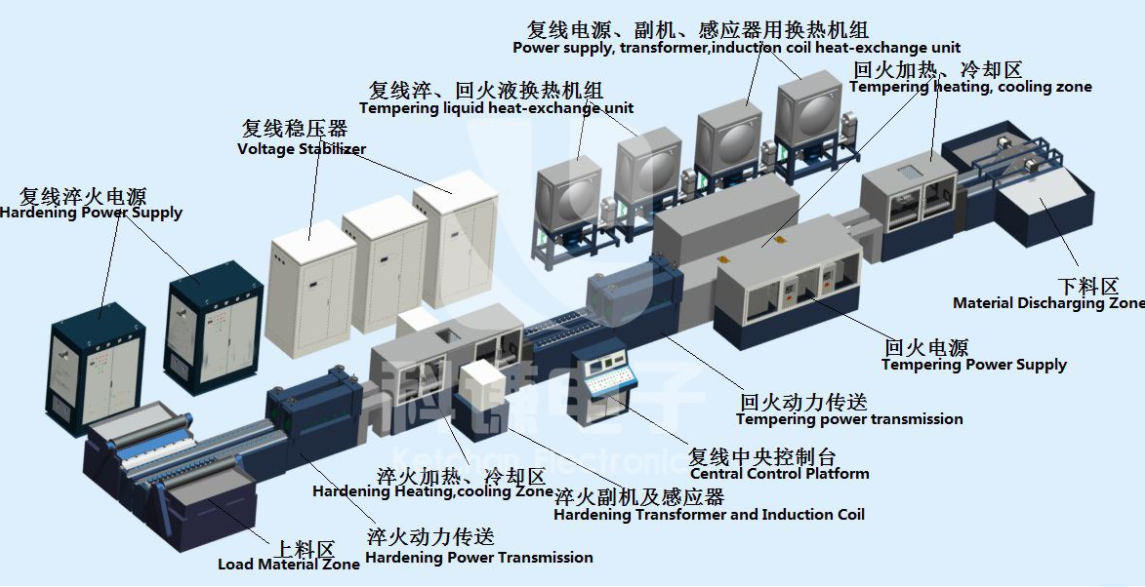

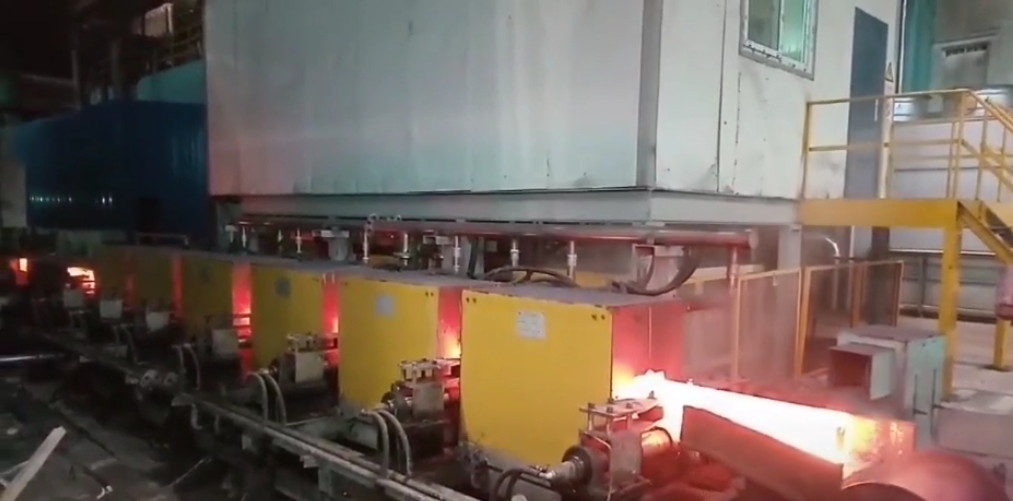

Large diameter steel pipe quenching and

Piston rod quenching and tempering produ

Grinding rod quenching and tempering pro

Steel pipe heat treatment production lin

Square steel quenching and tempering pro

Sucker rod quenching and tempering produ

Thickened petroleum steel pipe quenching

Round steel quenching and tempering prod

Steel pipe quenching and tempering produ

Steel plate quenching and tempering prod

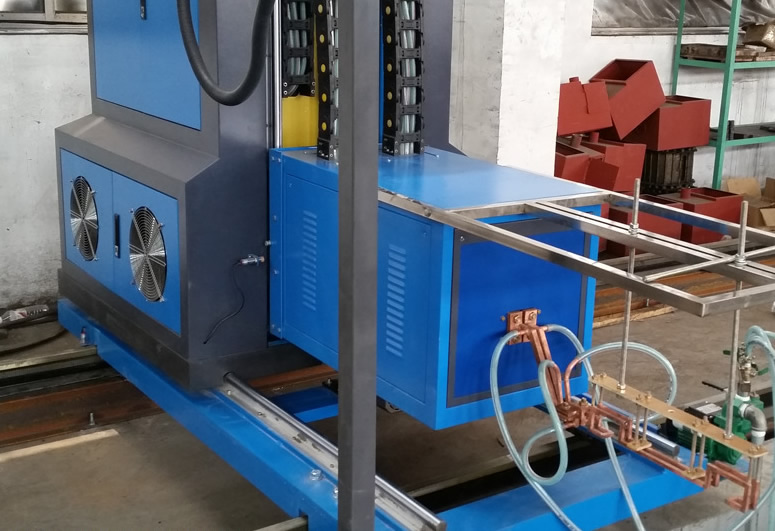

Induction Hardening Machine -

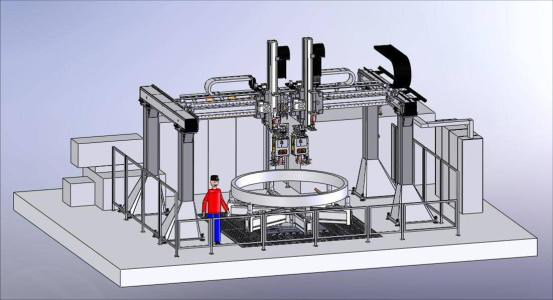

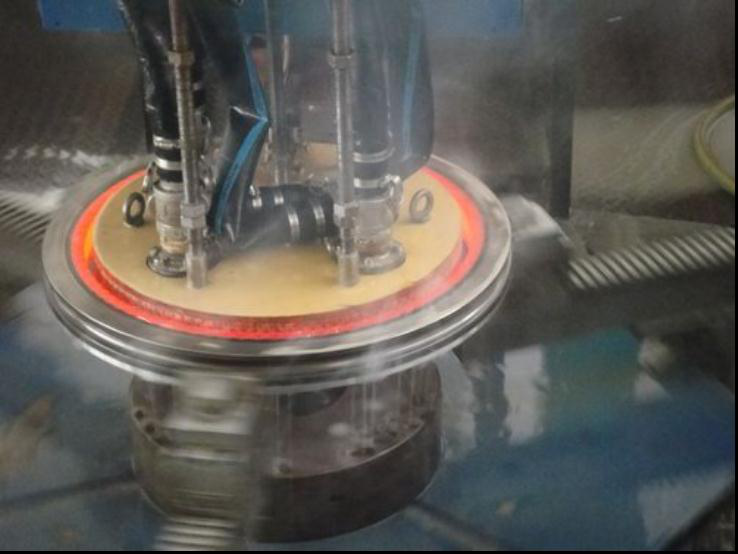

Flywheel ring gear high frequency quench

Oil drill pipe quenching and tempering p

Drill pipe hardening and tempering line

Bar quenching and tempering production l

Quenching and tempering production line

Gear hardening machine

Hand-held induction heater

Induction forging machine

induction heating machine

Induction heater

High frequency induction heater

Super audio induction heating machine

Super audio induction heating furnace

Guideway quenching integrated machine to

Quenching equipment for machine tool rai

Round steel end heating furnace

Round steel induction heating furnace

Aluminum rod induction heating furnace

Steel slab induction heating furnace

Square steel induction heating furnace

Billet induction heating furnace

Product Class

Copyright© 2007-2013 songdao Electric furnace manufacturing Co,.Ltd All Rights Reserved

Tel:18037961302 Sales hot line ( 24 hours service): 18037961302

E-Mail:firstfurnace@gmail.com

Adress: Luoxin Industrial Park, Luoyang, Henan

Tel:18037961302 Sales hot line ( 24 hours service): 18037961302

E-Mail:firstfurnace@gmail.com

Adress: Luoxin Industrial Park, Luoyang, Henan