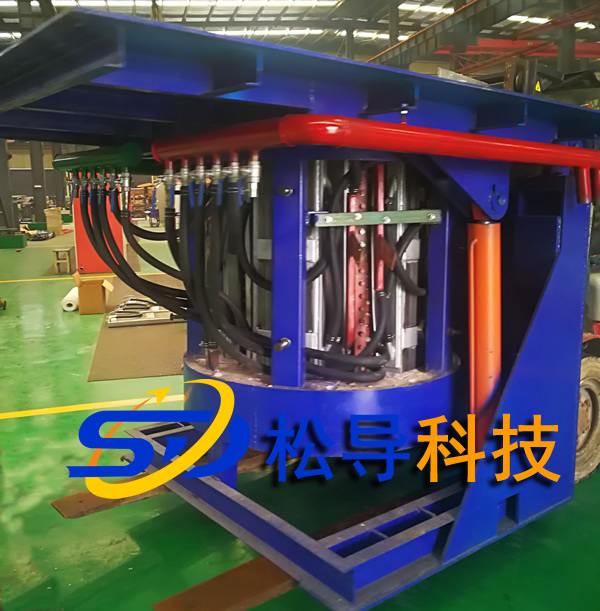

[Intermediate Frequency Induction Melting Furnace] What advantages does the medium frequency induction melting furnace play in its use: Many companies need heating equipment in the process of producing products. The number of heating equipment on the market is heavy, diverse, and widely used. The medium frequency induction melting furnace is a novel type of equipment, which is mainly used in the iron ore industry and brings convenience to iron ore production. The medium frequency induction melting furnace has many advantages and attracts consumers' purchases.

Second, the medium frequency magnetic field has a magnetic stirring effect on the molten metal, which is favorable for uniform composition and scumming.

Third, 24-hour uninterrupted smelting capacity;

Fourth, it is convenient to replace furnace bodies with different weights, different materials and different furnace modes to meet various melting requirements; vertical melting furnace, hand-type melting furnace, electric melting furnace, school laboratory melting furnace, portable High frequency melting furnace.

Fifth, energy saving and energy saving; the power supply adopts IGBT imported power device, which is more integrated and miniaturized, and the effective output power reaches over 90%.

Sixth, the use of ultra-small medium frequency induction heating power supply, energy saving 60% than the traditional thyristor medium frequency!

Seventh, heating and heat transfer is good, temperature is uniform

Eighth, ultra-small size, light weight, movable, less than 1 square meter

Ninth, according to the recommended equipment and maximum melting amount, each furnace smelting time is 20-30 minutes