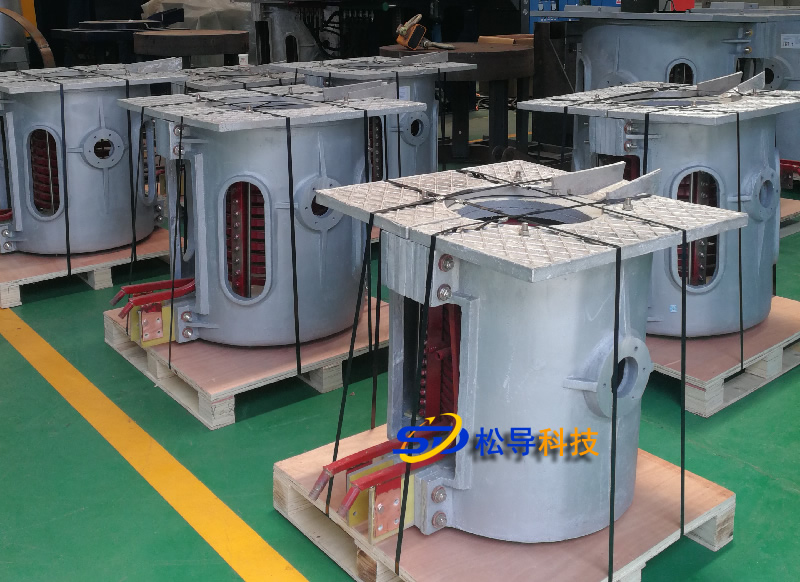

Detection of main components of induction melting furnace

SCR detection method

Use a digital multimeter 200KΩ to measure the thyristor forward and reverse resistance, which should be between 3KΩ and 100KΩ (the resistance is affected by the water circuit and the parallel voltage equalization resistance).

Use a digital multimeter 200Ω to measure the thyristor gate resistance, which should be between 10Ω and 30Ω.

Capacitor detection method

Disconnect the connecting copper bars of the capacitor. Use an insulated shaker to test whether each column of each capacitor is charged and discharged, and it should be able to charge and discharge normally.

Induction melting furnace detection method

Observe whether the short circuit is short between the turns: whether the coil is insulated from the protective ground. Induction coils are short-circuited between turns, and such faults are particularly prone to occur in small-sized medium-frequency induction furnaces. Because the furnace is small, it is deformed by thermal stress during operation, resulting in a short circuit between turns, and the fault is characterized by a large current and a higher operating frequency than usual. .

The induction coil leaks water, which may cause the coil to ignite between the turns, and must be repaired in time to run.

The molten steel sticks to the induction coil, and the steel slag is hot and red, which will cause the copper tube to burn through and must be cleaned up in time.