Sales hot line ( 24 hours service): 18037961302

E-Mail: firstfurnace@gmail.com

whatsapp:+8618037961302

Adress: Luoxin Industrial Park, Luoyang, HenanLarge diameter steel pipe quen

Piston rod quenching and tempe

Grinding rod quenching and tem

High frequency induction heate

Quenching equipment for machin

Round steel end heating furnac

Steel pipe heat treatment prod

Square steel quenching and tem

Sucker rod quenching and tempe

Thickened petroleum steel pipe

Round steel quenching and temp

Steel pipe quenching and tempe

Steel plate quenching and temp

Induction Hardening Machine&nb

Flywheel ring gear high freque

0.5T Parallel Intermediate Frequency Furnace

1 , the main purpose of 0.5T parallel intermediate frequency furnace

0.5T parallel IF melting furnace is mainly applied to steel, iron, copper, aluminum and alloys, having a high melting efficiency, energy-saving effect, a uniform metal composition, burning small, quick temperature rise, easy temperature control and so, for various metal melt.

2 , 0.5T parallel intermediate frequency furnace consists of:

400kw parallel intermediate frequency power supply - steel shell furnace body - water cooled cable - remote control box - ZXZ- 40T closed loop cooling tower.

3 , 0.5T parallel intermediate frequency furnace price summary table

The price of the 0.5T parallel intermediate frequency furnace is calculated according to the power of the intermediate frequency power supply and the volume of the furnace body. Different configuration prices vary. This price is for reference only. Contact us will have a very low price, please consult the specific price. Firstfurnace@gmail.com

|

Device name |

Total price (yuan) |

|

0.5T parallel intermediate frequency furnace |

¥ 131800 yuan |

SDBL-400kw 0.5T parallel intermediate frequency furnace configuration

|

Item name |

Specification model |

|

400kw parallel intermediate frequency power supply |

KGPS- 400kw / 0.5T |

|

Steel shell body |

GW- 0.5T |

|

Water cooled cable |

LHSD- 40 0 square |

|

Leakage alarm system |

LB T -1 |

|

Remote console |

H T -YK |

4, Power 0.5T parallel IF furnace tonnage method of selecting power consumption.

|

SDBL -400 kw |

Aluminum shell body |

Steel shell body |

|

Parallel intermediate frequency power supply |

400kw |

400kw |

|

Phase voltage |

3* 380V |

6* 380V |

|

Electric furnace rated voltage |

1500V |

1500V |

|

Melting rate |

About 0.5T /H |

About 0.5 T /H |

|

Rated Capacity |

0.5T |

0.5T |

|

Rated temperature |

1700 °C |

1700 °C |

|

Intermediate frequency power rectifier |

3- phase 6- pulse rectification |

6- phase 12- pulse rectification |

|

Power factor |

≥0.9 2 |

≥0.9 2 |

|

Tilting method: |

Optional gearbox or hydraulic |

Optional gearbox or hydraulic |

|

power supply |

KGPS-1/ 400kw |

KGPS-1/ 400kw |

|

Compensation capacitor cabinet |

set |

set |

|

stove |

Aluminum shell furnace |

Steel shell mechanism furnace (including yoke) |

|

Inclined furnace |

Reducer |

Hydraulic |

|

Water cooled cable |

Two |

Two |

|

Decidua |

One |

One |

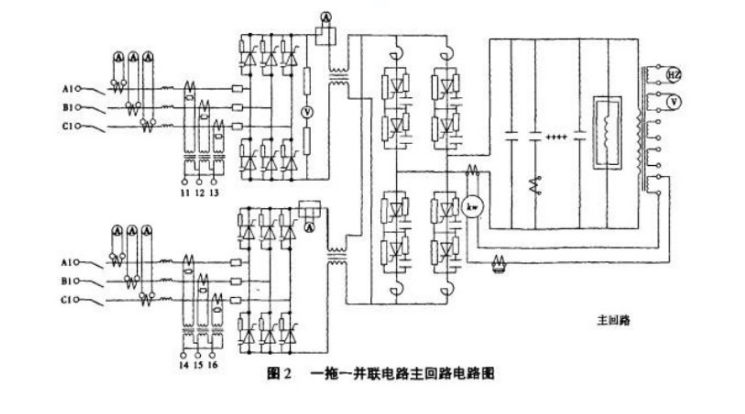

6 , 0.5T parallel intermediate frequency furnace circuit diagram :

Iron induction furnace

Aluminum melting furnace

Copper melting furnace

Small steel melting furnace

Small induction melting furnace

Induction iron furnace

3T intermediate frequency iron melting f

0.25T Intermediate Frequency Furnace

0.5T Intermediate Frequency Furnace

Medium Frequency Furnace

2T Induction Melting Furnace

1T Induction Melting Furnace

500kg Induction Melting Furnace

250kg Induction Melting Furnace

Induction Melting Furnace

3 T Induction Melting Furnace

5T Induction Melting Furnace

1T One Belt Two Intermediate Frequency F

5T One Belt Two Intermediate Frequency F

3T One Belt Two Intermediate Frequency F

2T One Belt Two Intermediate Frequency F

5T Parallel Intermediate Frequency Furna

5T Intermediate Frequency Furnace

5T Series Intermediate Frequency Furnace

3T Series Intermediate Frequency Furnace

2T Series Intermediate Frequency Furnace

1T Series Intermediate Frequency Furnace

0.5T Series Intermediate Frequency Furna

0.25T Series Intermediate Frequency Furn

1T Parallel Intermediate Frequency Furna

2T Parallel Intermediate Frequency Furna

0.5T Parallel Intermediate Frequency Fur