Sales hot line ( 24 hours service): 18037961302

E-Mail: firstfurnace@gmail.com

whatsapp:+8618037961302

Adress: Luoxin Industrial Park, Luoyang, HenanLarge diameter steel pipe quen

Piston rod quenching and tempe

Grinding rod quenching and tem

High frequency induction heate

Quenching equipment for machin

Round steel end heating furnac

Steel pipe heat treatment prod

Square steel quenching and tem

Sucker rod quenching and tempe

Thickened petroleum steel pipe

Round steel quenching and temp

Steel pipe quenching and tempe

Steel plate quenching and temp

Induction Hardening Machine&nb

Flywheel ring gear high freque

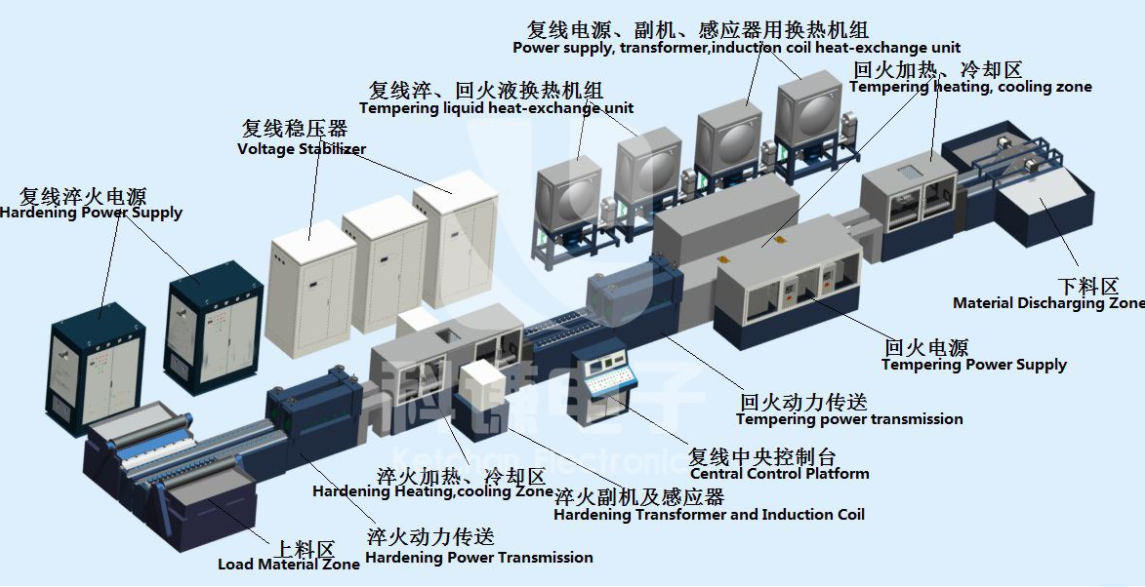

Piston rod quenching and tempering production line

Piston rod quenching and tempering production line

1. Process:

When the piston rod during quenching, is generally carried out after the rough grinding in an induction furnace hardening treatment, the induction heating to 1000 ¡æ -1020 ¡æ, 0.6MPa using a compressed air injection 0.05 cooled, hardened layer depth of 1.5 - 2.5 mm, Straightening treatment is carried out after quenching. Then, at 200 ¡æ ~ 220 ¡æ tempering, incubation time 1 - 2 hours, furnace cooled to room temperature, the hardness of HRC50 or more.

2. Summary of selection of technical parameters such as piston rod quenching and tempering production lines

|

size |

Control System |

Matching power supply |

|

¦µ 10- ¦µ 28mm |

PLC intelligent control |

KGPS350KW £«KGPS160KW |

|

¦µ 42- ¦µ 48mm |

PLC intelligent control |

KGPS250KW £«KGPS160KW |

|

¦µ 30- ¦µ 60mm |

PLC intelligent control |

KGPS250KW £«KGPS160KW |

|

¦µ 30- ¦µ 60mm |

PLC intelligent control |

KGPS250KW £«KGPS160KW |

|

¦µ 35- ¦µ 60mm |

PLC intelligent control |

KGPS300KW £«KGPS160KW |

|

¦µ 30- ¦µ 110mm |

PLC intelligent control |

KGPS400KW £«KGPS160KW |

|

¦µ 80- ¦µ 110mm |

PLC intelligent control |

KGPS600KW £«KGPS160KW |

|

[Phi 73.2- [Phi 88.9mm- [Phi 139.7 mm |

PLC intelligent control |

KGPS500KW £«KGPS100KW |

|

¦µ 95- ¦µ 114mm |

PLC intelligent control |

KGPS250KW £«KGPS160KW |

|

Customized production according to the actual needs of customers |

||

Iron induction furnace

Aluminum melting furnace

Copper melting furnace

Small steel melting furnace

Small induction melting furnace

Induction iron furnace

3T intermediate frequency iron melting f

0.25T Intermediate Frequency Furnace

0.5T Intermediate Frequency Furnace

Medium Frequency Furnace

2T Induction Melting Furnace

1T Induction Melting Furnace

500kg Induction Melting Furnace

250kg Induction Melting Furnace

Induction Melting Furnace

3 T Induction Melting Furnace

5T Induction Melting Furnace

1T One Belt Two Intermediate Frequency F

5T One Belt Two Intermediate Frequency F

3T One Belt Two Intermediate Frequency F

2T One Belt Two Intermediate Frequency F

5T Parallel Intermediate Frequency Furna

5T Intermediate Frequency Furnace

5T Series Intermediate Frequency Furnace

3T Series Intermediate Frequency Furnace

2T Series Intermediate Frequency Furnace

1T Series Intermediate Frequency Furnace

0.5T Series Intermediate Frequency Furna

0.25T Series Intermediate Frequency Furn

1T Parallel Intermediate Frequency Furna

2T Parallel Intermediate Frequency Furna

0.5T Parallel Intermediate Frequency Fur