Sales hot line ( 24 hours service):+86 13015583380

E-Mail: firstfurnace@gmail.com

whatsapp:+86 13015583380

Adress: Luoxin Industrial Park, Luoyang, HenanLarge diameter steel pipe quen

Piston rod quenching and tempe

Grinding rod quenching and tem

High frequency induction heate

Quenching equipment for machin

Round steel end heating furnac

Steel pipe heat treatment prod

Square steel quenching and tem

Sucker rod quenching and tempe

Thickened petroleum steel pipe

Round steel quenching and temp

Steel pipe quenching and tempe

Steel plate quenching and temp

Induction Hardening Machine&nb

Flywheel ring gear high freque

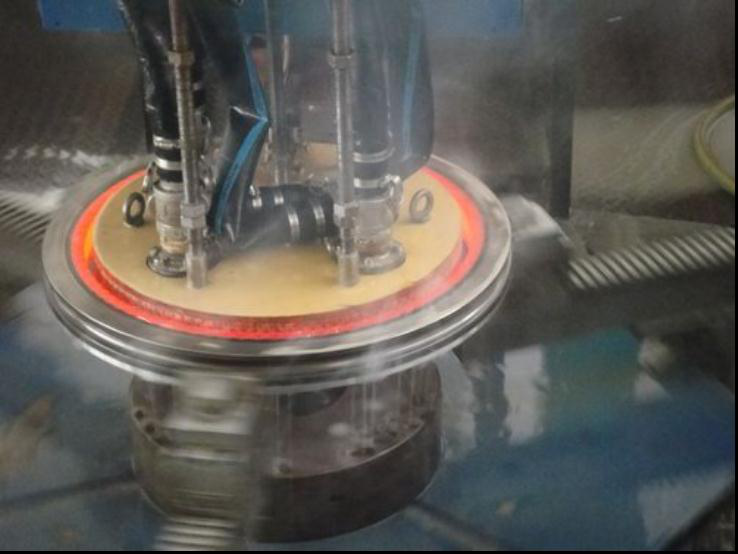

Gear hardening machine

Gear hardening machine

The necessity of gear hardening

Some parts (including gears) are subjected to alternating loads such as torsion and bending, impact loads, and their surface layer bears higher stress than the core. In the occasion of friction, the surface layer is continuously worn. Therefore, the surface layer of some parts is required to have high strength, high hardness, high wear resistance and high fatigue limit. Only surface strengthening can meet the above requirements. Because surface quenching has the advantages of small deformation and high productivity, it is widely used in production.

The composition of the gear quenching machine tool:

1. Bed part: The gear quenching machine adopts a welded bed structure, and the overall stress relief annealing is carried out. The surface of the main exposed parts has been specially treated and has good rust and corrosion resistance.

2. Workbench system: Using stepping motor, the ball screw is driven by the variable speed mechanism to realize the lifting movement of the upper workbench. The moving speed is steplessly adjustable, the transmission is light and fast, the guiding accuracy is high, and the positioning is accurate.

3. Spindle rotation system: the asynchronous motor drives the spindle to rotate through the speed change mechanism and the transmission shaft. Use frequency conversion speed regulation to realize stepless adjustment of parts speed.

4. Upper center adjustment mechanism: The upper center adjustment adopts electric adjustment, which can realize the clamping of workpieces of different lengths.

5. Electrical control part: The electrical control part of the gear quenching machine tool is composed of a numerical control system, a frequency converter, an intermediate relay, etc. The power supply line: 3 phase, 380V, 1.5Kw; can store more than 20 kinds of parts of the quenching process, through The numerical control keyboard can program and store various programs. The machine tool is equipped with functions such as power failure protection and offside protection, which has high safety and reliability.

6. Cover frame: The cover frame is made of thick steel plate. Well-made, beautiful appearance, and generous color. The upper part of the cover frame is equipped with glass windows and sliding doors, which can not only prevent the cooling water from splashing, but also facilitate the loading and unloading of parts and monitoring the quenching process.

Performance characteristics of gear quenching machine tools:

1. The gear quenching machine adopts the PLC industrial digital control system, which has advanced performance and convenient debugging and use, which can meet the quenching needs of complex workpieces to a large extent.

2. The guide rail adopts linear bearings with high precision, low friction and long life.

3. The gear quenching machine tool can realize quenching methods: continuous scanning quenching, simultaneous quenching, segmented continuous scanning quenching (set by the degree of segmentation, no stroke switch, the same below), segmented simultaneous quenching.

4. The device balances the weight through sprocket and chain.

5. Low operating cost. The drive motor for workpiece rotation only needs 250W, and the power consumption of the whole machine is less than one-fifth of the mechanical equipment.

6. The electrical control system of the gear quenching machine tool reserves the quenching heating and cooling water control interfaces. The quenching process and cooling process can be controlled according to process requirements.

7. Convenient use and maintenance, low failure rate and no leakage, which solves the old-fashioned machine tool problem.

8. High degree of automation and high production efficiency.

9. Applicable typical workpieces (within the range of corresponding dimensions) shafts: various shafts, stepped shafts, gear shafts, camshafts, half shafts, outer circles and end faces of disc-shaped parts, etc.

10. The gear quenching machine adopts a profile structure body, low cost, light weight, economical and practical.

Iron induction furnace

Aluminum melting furnace

Copper melting furnace

Small steel melting furnace

Small induction melting furnace

Induction iron furnace

3T intermediate frequency iron melting f

0.25T Intermediate Frequency Furnace

0.5T Intermediate Frequency Furnace

Medium Frequency Furnace

2T Induction Melting Furnace

1T Induction Melting Furnace

500kg Induction Melting Furnace

250kg Induction Melting Furnace

Induction Melting Furnace

3 T Induction Melting Furnace

5T Induction Melting Furnace

1T One Belt Two Intermediate Frequency F

5T One Belt Two Intermediate Frequency F

3T One Belt Two Intermediate Frequency F

2T One Belt Two Intermediate Frequency F

5T Parallel Intermediate Frequency Furna

5T Intermediate Frequency Furnace

5T Series Intermediate Frequency Furnace

3T Series Intermediate Frequency Furnace

2T Series Intermediate Frequency Furnace

1T Series Intermediate Frequency Furnace

0.5T Series Intermediate Frequency Furna

0.25T Series Intermediate Frequency Furn

1T Parallel Intermediate Frequency Furna

2T Parallel Intermediate Frequency Furna

0.5T Parallel Intermediate Frequency Fur