Sales hot line ( 24 hours service): 18037961302

E-Mail: firstfurnace@gmail.com

whatsapp:+8618037961302

Adress: Luoxin Industrial Park, Luoyang, HenanLarge diameter steel pipe quen

Piston rod quenching and tempe

Grinding rod quenching and tem

High frequency induction heate

Quenching equipment for machin

Round steel end heating furnac

Steel pipe heat treatment prod

Square steel quenching and tem

Sucker rod quenching and tempe

Thickened petroleum steel pipe

Round steel quenching and temp

Steel pipe quenching and tempe

Steel plate quenching and temp

Induction Hardening Machine&nb

Flywheel ring gear high freque

Aluminum rod induction heating furnace

Aluminum rod induction heating furnace

Aluminum rod induction heating furnace is used to heat aluminum ingots, and the oxidation loss can be controlled below 0.05-0.5% , while heating with a combustion furnace, the oxidation loss generally reaches 2.5-3.0% , so induction heating furnaces generally do not need gas protection. The main body of the induction is only one sensor. This kind of furnace does not require a complicated piping system like a combustion furnace, and does not need a combustion furnace, such as a thick furnace wall, so it can be compactly organized in the production line, or even combined In other processing machinery.

Summary of parameters for heating aluminum billets in aluminum rod induction heating furnace

|

Aluminum billet size |

Aluminum billet length |

Heating temperature |

Production capacity |

|

60 × 60mm |

3m-4m |

1150 |

25T/H |

|

75 × 75mm |

3m-4m |

1150 |

25T/H |

|

100 × 100mm |

2m |

1150 |

7T/H |

|

120 × 120mm |

|

1150 |

30T/H |

|

120 × 120mm |

11.5-12.5m |

1150 |

90T/H |

|

125 × 125mm |

6m |

1150 |

8T/H |

|

125 × 125mm |

2m |

1150 |

7T/H |

|

130 × 130mm |

6m |

1150 |

50T/H |

|

135 × 135mm |

6m |

1150 |

100T/H |

|

150 × 150mm |

11.5-12.5m |

1150 |

70T/H |

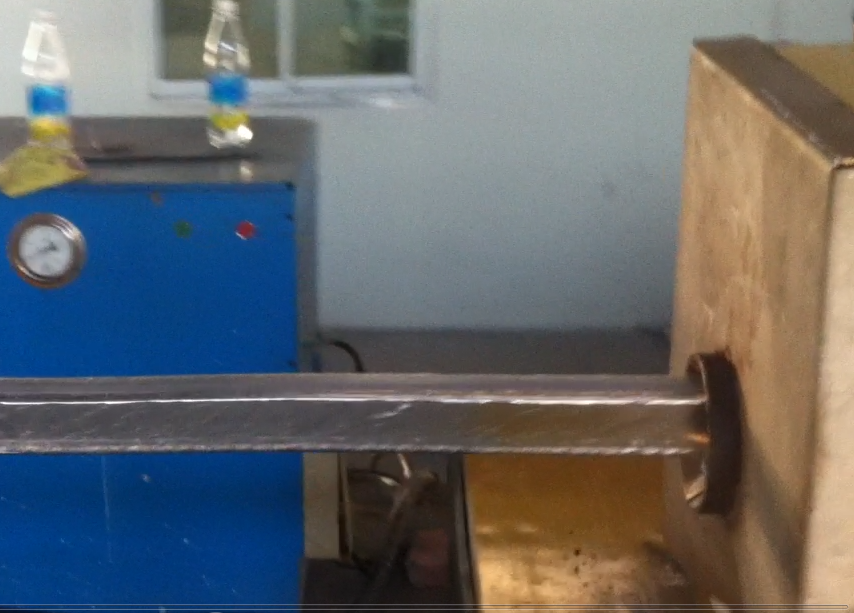

Aluminum rod induction heating furnace application assembly drawing

What parameters are required for the selection of aluminum rod induction heating furnace ?

The selection of aluminum rod induction heating furnace generally requires the following parameters:

First: the shape of the heated aluminum ingot, the outer dimensions, and the weight of the heated workpiece.

Second: the material of the workpiece to be heated (generally induction heating, only for metal conductor materials).

Third: the time required for the heating of the heated workpiece to the target temperature, and the target temperature.

Once the above three points are clear, the bar heating furnace can be selected including matching power.

What are the characteristics of the aluminum rod induction heating furnace structure?

1. Furnace structure: The heating furnace of our company is designed as an integral quick-change type. When the furnace body is changed for different heating workpieces, rapid replacement can be realized.

2. Furnace lining: The furnace lining adopts silicon carbide or integral knotting method, and the service temperature is above 1450℃.

3. Protection: automatic shutdown when the water temperature exceeds 65℃.

4. Induction furnace water-cooled track: A water-cooled track is installed on the lining of the induction furnace.

How to calculate the power supply of aluminum rod induction heating furnace ?

P=(0.168×200×693)/(0.24×0.6×145)=1029KW where: 0.168—average specific heat of ferrous metal; 2080—workpiece mass (Kg); 200—workpiece heating temperature rise; 0.24— Work-heat equivalent; 0.6—average efficiency (in this example, 0.6, generally 0.5~0.65, and special-shaped sensors are lower, 0.4); 145—working cycle (seconds)

According to the above calculation, a 1KHz induction heating furnace with a rated power of 1500KW can be configured to meet the needs.

How to choose and use aluminum rod induction heating furnace ? Mainly to consider from several aspects:

1. The shape and size of the heated workpiece

For large workpieces, bars, and solid materials, use bar heating furnaces with relatively high power and low frequency; for small workpieces, tubes, plates, gears, etc., use bar heating furnaces with relatively low power and high frequency.

2. The depth and area that need to be heated

The heating depth is deep, the area is large, and the overall heating should be an induction heating furnace with high power and low frequency; the heating depth is shallow, the area is small, and local heating is used, and the induction heating furnace with relatively low power and high frequency should be selected.

3. Required heating rate

If the heating speed is fast, an induction heating furnace with relatively large power and relatively high frequency should be used.

4. Continuous working hours of equipment

The continuous working time is long, and the induction heating furnace with a slightly larger power is selected .

5. The connection distance between the sensing component and the equipment

The connection is long, and even water-cooled cable connection is required. Therefore, an induction heating furnace with a relatively large power should be used.

6. Process requirements

Generally speaking, for processes such as quenching and welding, you can select a lower power and a higher frequency; for annealing and tempering processes, select a higher relative power and a lower frequency; red punching, hot forging, smelting, etc., need If the heating effect is good, the power should be larger and the frequency should be lower.

7. The material of the workpiece

Among the metal materials, the higher melting point is relatively large, the lower melting point is relatively small; the lower resistivity is higher, and the higher resistivity is lower.

Features of aluminum rod induction heating furnace :

1. The operation panel adopts a color LCD display, a large-size touch screen, a high-definition operation screen, and the operation safety protection system can be operated with peace of mind even for the first time users.

2. High heating temperature: It depends on the material of the workpiece to be heated and the length of heating time. It can reach any temperature and can heat any metal;

3. High efficiency and energy saving: the energy conversion rate is higher than 85%, which is twice that of the old-fashioned intermediate frequency induction heating furnace equipment;

4. Automatic control: the power and time of the heating and heat preservation process can be adjusted, which is conducive to improving the thermal quality and heating repeatability, and it can also work continuously for 24 hours;

5. High reliability: This machine has a complete protection circuit. When any of the power supply voltage, water pressure, water temperature, load current and other parameters fail to meet the requirements, the machine will automatically stop working;

6. The aluminum rod induction heating furnace is easy to install: just connect the power supply and water;

7. Aluminum rod induction heating furnace is small in size, safe and convenient to operate.

The price of aluminum rod induction heating furnace: the price of

aluminum rod induction heating furnace is about 10,000 yuan per unit, and the expensive one is tens of thousands of yuan. The price of aluminum rod induction heating furnace is affected by many aspects, such as brand, category, specification, market, etc. Before choosing to buy, it is necessary to understand and compare in many aspects.

Iron induction furnace

Aluminum melting furnace

Copper melting furnace

Small steel melting furnace

Small induction melting furnace

Induction iron furnace

3T intermediate frequency iron melting f

0.25T Intermediate Frequency Furnace

0.5T Intermediate Frequency Furnace

Medium Frequency Furnace

2T Induction Melting Furnace

1T Induction Melting Furnace

500kg Induction Melting Furnace

250kg Induction Melting Furnace

Induction Melting Furnace

3 T Induction Melting Furnace

5T Induction Melting Furnace

1T One Belt Two Intermediate Frequency F

5T One Belt Two Intermediate Frequency F

3T One Belt Two Intermediate Frequency F

2T One Belt Two Intermediate Frequency F

5T Parallel Intermediate Frequency Furna

5T Intermediate Frequency Furnace

5T Series Intermediate Frequency Furnace

3T Series Intermediate Frequency Furnace

2T Series Intermediate Frequency Furnace

1T Series Intermediate Frequency Furnace

0.5T Series Intermediate Frequency Furna

0.25T Series Intermediate Frequency Furn

1T Parallel Intermediate Frequency Furna

2T Parallel Intermediate Frequency Furna

0.5T Parallel Intermediate Frequency Fur