Sales hot line ( 24 hours service): 18037961302

E-Mail: firstfurnace@gmail.com

whatsapp:+8618037961302

Adress: Luoxin Industrial Park, Luoyang, HenanLarge diameter steel pipe quen

Piston rod quenching and tempe

Grinding rod quenching and tem

High frequency induction heate

Quenching equipment for machin

Round steel end heating furnac

Steel pipe heat treatment prod

Square steel quenching and tem

Sucker rod quenching and tempe

Thickened petroleum steel pipe

Round steel quenching and temp

Steel pipe quenching and tempe

Steel plate quenching and temp

Induction Hardening Machine&nb

Flywheel ring gear high freque

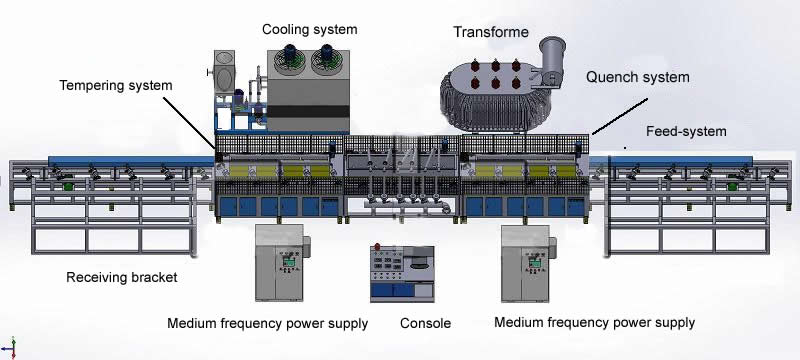

Square steel quenching and tempering production line

Equipment name: Square steel quenching and tempering production line

Workpiece material: Carbon steel alloy steel

Workpiece size: 20 x20 ゛160 x160 mm

Workpiece length: 2-20m

Power range: 1 6 0- 1 000KW

Closed loop temperature control: Controlled by the American Leitai two-color thermometer Temperature

control system: PLC man-machine interface full-automatic intelligent control

Square steel quenched and tempered , specifications may process the steel 20x20 - 160x160 mm. There are five sets of coils in the whole line, which are controlled by five completely independently adjustable frequency conversion modules. The last group of each zone is used as a holding zone to obtain a better austenitizing effect. The grinding rod cooling system is water-cooled and consists of 5 quenching water rings and a linear cutting nozzle. The entire process of quenching and tempering of the grinding rod is continuously transported by a continuous inclined roller table. The grinding rod advances in a self-rotating manner, which can ensure the uniformity of heating and cooling of the grinding rod and obtain better flatness.

1. The composition of the square steel quenching and tempering production line :

1. Feeding mechanism and discharging mechanism

2. Conveying roller table (the workpiece is being fed at a constant speed while rotating, and the operation is stable, the speed is adjustable, and the heating is more uniform)

3. Quenching induction heating furnace system

4. Quenching spray system

5. Tempering induction heating furnace system

6. The PLC main console (including frequency conversion and temperature control, Huayan industrial computer, remote start, etc.) is to directly operate the entire quenching and tempering equipment on the central console, and only one person can operate the steel pipe The quenching and tempering production line saves labor and costs.

7. Power range of quenching induction heating furnace : KGPS/IGBT 160-1300KW

8. Power range of tempering induction heating furnace : KGPS/IGBT 160-750KW

2. Description of control system for square steel quenching and tempering production line :

The main console adopts German Siemens PLC and Taiwan Huayan industrial control system as the core control part, which automatically matches and adjusts the mechanical operating parameters, quenching and tempering parameters, power supply, etc. of the entire system , and displays, stores and stores various parameters. Printing and other functions.

1. Recipe management function:

Powerful formula management system, after inputting the steel grade, pipe diameter and wall thickness parameters to be produced, the relevant parameters are automatically called, and there is no need to manually record, consult, and input the parameter values required by various workpieces.

2. History curve function:

The PLC master console displays traceable process history curves (standard configuration in industrial computer systems), with a recording accuracy of 0.1 second, vividly and accurately reproducing the processing temperature trend graph of a single product. Up to 1T capacity storage space, permanent preservation of all product process records for decades.

3. Historical records:

The traceable process data table can take out multiple sets of sampling points on each product, and accurately reproduce the processing temperature value of each section of a single product. In the touch screen system, there is no storage space limitation at all, and all product process records for decades are permanently stored.

Third, the basic configuration of the square steel quenching and tempering production line

|

Serial number |

content |

quantity |

Remark |

||

|

1 |

S11-630kvA power transformer |

1 set |

|

||

|

2 |

Thyristor intermediate frequency power supply KGPS- 5 0 0/1 |

1 set |

|

||

|

3 |

Quenching transformer |

1 set |

|

||

|

3 |

Quenching induction heater |

|

Including water-cooled rails |

||

|

3 .1 |

GTR 18 |

1 set |

|

||

|

3.2 |

GTR 25 |

1 set |

|

||

|

3.3 |

GTR 29 |

1 set |

|

||

|

3.4 |

GTR 36 |

1 set |

|

||

|

4 |

Tempering induction heater |

|

Including water-cooled rails |

||

|

4 .1 |

GTR 18 |

1 set |

|

||

|

4.2 |

GTR 25 |

1 set |

|

||

|

4.3 |

GTR 29 |

1 set |

|

||

|

4.4 |

GTR 36 |

1 set |

|

||

|

5 |

Quenching induction heater bed |

1 set |

|

||

|

6 |

Back to fire induction heater bed |

1 set |

|

||

|

14 |

Loading end bed |

1 set |

|

||

|

8 |

Cutting end bed |

|

|

||

|

9 |

Feeding mechanism |

|

|

||

|

10 |

Feeding mechanism |

|

|

||

|

11 |

Transmission roller mechanism |

|

|

||

|

12 |

Pressure roller feeding device |

1 set |

|

||

|

13 |

Quenching water spray device |

|

|

||

|

14 |

Electrical control core |

1 set |

|

||

|

14 . 1 |

Configuration Software (MCGS system) |

1 set |

|

||

|

14 . 2 |

A programmable controller (the SIEMENS the SIMATIC S 14 - . 3 00) |

1 set |

|

||

|

14 . 3 |

LCD screen |

1 set |

|

||

|

14 . 4 |

Dual Colorimetric Infrared Thermometer ( USA Leitai) |

1 set |

|

||

|

14 . 5 |

Photoelectric switch |

4 sets |

|

||

|

14 . 6 |

Control cabinet (including variable frequency drive equipment) |

1 set |

|

||

|

14 . 7 |

Console |

1 set |

|

||

|

15 |

Cooling water system ( ZXZ - 60T ) part |

1 set |

|

||

|

|

|

|

|||

|

Water pipe ppr |

|

The water cooling tower is within 10 meters of the power cabinet |

|||

|

16 |

IF power inlet copper bar |

1 set |

|

||

|

17 |

Electrical and waterway installation and commissioning |

1 set |

|

||

|

18 |

freight |

1 set |

|

||

Iron induction furnace

Aluminum melting furnace

Copper melting furnace

Small steel melting furnace

Small induction melting furnace

Induction iron furnace

3T intermediate frequency iron melting f

0.25T Intermediate Frequency Furnace

0.5T Intermediate Frequency Furnace

Medium Frequency Furnace

2T Induction Melting Furnace

1T Induction Melting Furnace

500kg Induction Melting Furnace

250kg Induction Melting Furnace

Induction Melting Furnace

3 T Induction Melting Furnace

5T Induction Melting Furnace

1T One Belt Two Intermediate Frequency F

5T One Belt Two Intermediate Frequency F

3T One Belt Two Intermediate Frequency F

2T One Belt Two Intermediate Frequency F

5T Parallel Intermediate Frequency Furna

5T Intermediate Frequency Furnace

5T Series Intermediate Frequency Furnace

3T Series Intermediate Frequency Furnace

2T Series Intermediate Frequency Furnace

1T Series Intermediate Frequency Furnace

0.5T Series Intermediate Frequency Furna

0.25T Series Intermediate Frequency Furn

1T Parallel Intermediate Frequency Furna

2T Parallel Intermediate Frequency Furna

0.5T Parallel Intermediate Frequency Fur