Sales hot line ( 24 hours service):+86 13015583380

E-Mail: firstfurnace@gmail.com

whatsapp:+86 13015583380

Adress: Luoxin Industrial Park, Luoyang, HenanLarge diameter steel pipe quen

Piston rod quenching and tempe

Grinding rod quenching and tem

High frequency induction heate

Quenching equipment for machin

Round steel end heating furnac

Steel pipe heat treatment prod

Square steel quenching and tem

Sucker rod quenching and tempe

Thickened petroleum steel pipe

Round steel quenching and temp

Steel pipe quenching and tempe

Steel plate quenching and temp

Induction Hardening Machine&nb

Flywheel ring gear high freque

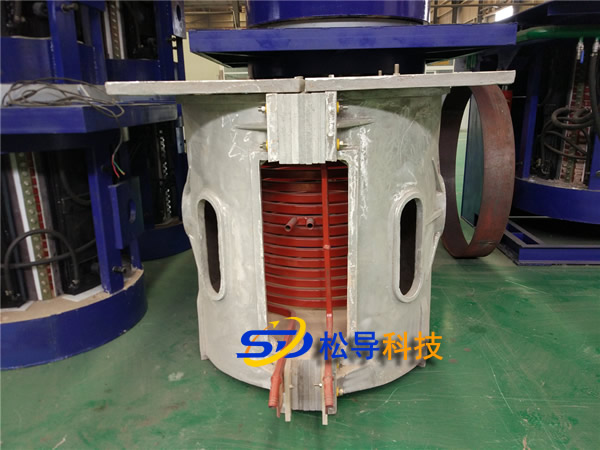

induction melting electric furnace graphite crucible use method

1: Medium-frequency electric furnace graphite crucible installation method: The bottom-filling material will build the intermediate-frequency electric furnace graphite crucible at the center, and the filling materials will be put into batches. The three-person rotary tools will be built around the building and solidified (5 minutes) and then put into 200M/ When the M operation is completed, the top should be finally built.

2: Drying: When the furnace is initially opened, the temperature is raised to 200 ° C to the use temperature. The temperature is maintained for 3 hours to make the intermediate frequency electric furnace graphite crucible firm to prevent gas and sand holes from occurring.

3: Melting method: every morning * furnace low temperature preheating (2 hours before shift) is put into normal power. When the soup is out, different heating curves cannot be set due to different refining materials, but rapid melting is not good.

4: Medium frequency electric furnace graphite crucible use method: * The furnace uses materials to make it into the furnace block. The bigger the better the article. Do not hit the intermediate frequency electric furnace graphite crucible. The second furnace has a little hot to make it easy to melt new materials, never Rapid melting, the intermediate frequency furnace graphite crucible contains molten soup can not be cooled, the attached oxide should be removed at any time.

5: The reason why the intermediate frequency furnace graphite crucible is bad: the longitudinal filler is uneven in the back filler, the graphite crucible in the intermediate frequency electric furnace is not in proper position, and the metal liquid material is impacted and impacted when it melts. Cross-break reason. It is easy to occur in the upper part and the lower part to rapidly melt the metal liquid. The upper part is broken: the back filler is not solid, and the intermediate frequency electric furnace graphite ruthenium is oxidized and impacted. Local melt loss: After the melting, the metal material is not continuously input.

Iron induction furnace

Aluminum melting furnace

Copper melting furnace

Small steel melting furnace

Small induction melting furnace

Induction iron furnace

3T intermediate frequency iron melting f

0.25T Intermediate Frequency Furnace

0.5T Intermediate Frequency Furnace

Medium Frequency Furnace

2T Induction Melting Furnace

1T Induction Melting Furnace

500kg Induction Melting Furnace

250kg Induction Melting Furnace

Induction Melting Furnace

3 T Induction Melting Furnace

5T Induction Melting Furnace

1T One Belt Two Intermediate Frequency F

5T One Belt Two Intermediate Frequency F

3T One Belt Two Intermediate Frequency F

2T One Belt Two Intermediate Frequency F

5T Parallel Intermediate Frequency Furna

5T Intermediate Frequency Furnace

5T Series Intermediate Frequency Furnace

3T Series Intermediate Frequency Furnace

2T Series Intermediate Frequency Furnace

1T Series Intermediate Frequency Furnace

0.5T Series Intermediate Frequency Furna

0.25T Series Intermediate Frequency Furn

1T Parallel Intermediate Frequency Furna

2T Parallel Intermediate Frequency Furna

0.5T Parallel Intermediate Frequency Fur