Sales hot line ( 24 hours service):+86 13015583380

E-Mail: firstfurnace@gmail.com

whatsapp:+86 13015583380

Adress: Luoxin Industrial Park, Luoyang, HenanLarge diameter steel pipe quen

Piston rod quenching and tempe

Grinding rod quenching and tem

High frequency induction heate

Quenching equipment for machin

Round steel end heating furnac

Steel pipe heat treatment prod

Square steel quenching and tem

Sucker rod quenching and tempe

Thickened petroleum steel pipe

Round steel quenching and temp

Steel pipe quenching and tempe

Steel plate quenching and temp

Induction Hardening Machine&nb

Flywheel ring gear high freque

Induction power frequency furnace for melting copper and its copper alloy is a commonly used melting method and has been widely used. The existing industrial frequency furnace is mainly composed of furnace shell, furnace lining, melting channel, induction coil, iron core and other components. The melting channel is a ring (solid) cast with the same metal liquid as the molten copper and its copper alloy. ). The working principle is that after the power frequency furnace is energized, the current enters the induction coil, and a large current is generated inside the melting groove by electromagnetic induction. Because the melting groove is a short-circuit ring, the melting groove is melted. As a result, the thermal energy in the melting channel is quickly transferred to the copper and its copper alloy in the furnace, and finally the copper and its copper alloy in the furnace are melted.

However, the problems with the melting of the above-mentioned industrial frequency furnace are:

First, the phenomenon of broken trench is prone to occur.

Because there is a melting ditch in this power-frequency furnace, it is necessary to keep the temperature in the furnace energized when not in production. Otherwise, if the power is cut off, the temperature of the copper solution will drop and the melting ditch will solidify. It will be easy to break the ditch when the power is re-transmitted, and the whole furnace will be scrapped.

Second, prone to blockage.

Because there are many impurities in melting the scrap copper, when the melting channel sample is heated and melted, these impurities will be concentrated together and block phenomenon will occur. These blocking phenomena will cause the melting ditch (or ditch template) in the melting to break and fail to switch on the current, making it unable to heat and melt, resulting in the entire furnace being scrapped. The original melting ditch must be taken out of the furnace (furnace cooling usually takes 2-3 days) and the new melting ditch must be rebuilt, resulting in a loss of time and a waste of funds and an increase in melting costs.

The purpose of the induction melting furnace for melting copper and its copper-copper alloy of the utility model is to overcome the above-mentioned shortcomings. The device eliminates the melting trench, and the phenomenon of broken trench and blocking of the trench will not occur, and a furnace can be stopped at any time. And open the furnace, save national power.

The technical solution of the induction melting furnace for melting copper and its copper-copper alloy is realized: an energy-saving melting induction melting furnace includes:

Furnace shell, intermediate frequency coil, light refractory lining, graphite melting furnace liner, graphite insulation furnace liner, furnace channel, valve. One side of the graphite melting furnace bile feed port is open, and the furnace channel connecting the graphite melting furnace bile and the graphite heat preservation furnace bile is 5 cm lower than the graphite melting furnace bile mouth.

After using copper and its copper-copper alloy to melt the induction melting furnace, when copper and its copper alloy are melted in the graphite melting furnace bladder, it enters the graphite insulation furnace bladder through the furnace bladder channel, and is then made into a finished product by a tractor. Because there is no melting groove in the graphite melting furnace, the power can be turned off when the work is completed, and the residual metal solution can be discharged through the valve. Therefore, compared with the existing induction power frequency furnace, the energy-saving melting induction melting furnace eliminates the melting ditch, eliminates the phenomenon of broken trenches and blockages, and can achieve production and start at any time, freely grasp the power on and power off time, and save the country. Energy, reduces melting costs, reduces maintenance costs, and improves work efficiency. At the same time, the energy-saving melting induction melting furnace also has the characteristics of simple structure and low construction cost.

BRIEF DESCRIPTION OF THE DRAWINGS

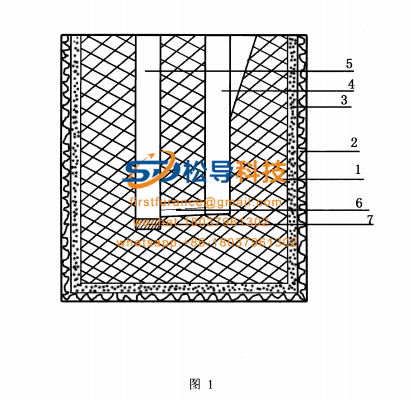

Figure 1 is a schematic diagram of the structure of the utility model

Specific embodiment of an induction melting furnace for melting copper and its copper-copper alloy

As shown in FIG. 1, the energy-saving melting induction melting furnace of the present invention includes a furnace shell 1, an intermediate frequency coil 2, a light refractory lining 3, a graphite melting furnace liner 4, a graphite heat-insulating furnace liner 5, a furnace duct 6, a valve 7, the graphite melting furnace bladder 4 end feeding port is open.

Turn on the power when working, add copper and its copper alloy from the graphite melting furnace liner 4, the current generates heat through the intermediate frequency coil 2, and the heat passes through the light refractory lining 3. The heat transfer of graphite makes the graphite melting furnace copper 4 and its copper The alloy melts, the solution flows into the graphite insulation furnace 5 through the furnace channel 6, and then is made into a finished product by the tractor. If the equipment needs to be repaired and the production is stopped for a long time, open the valve 7 at the bottom of the graphite insulation furnace 5 to remove a small amount of copper and Copper alloy solution, close valve 7, and finally power off

Iron induction furnace

Aluminum melting furnace

Copper melting furnace

Small steel melting furnace

Small induction melting furnace

Induction iron furnace

3T intermediate frequency iron melting f

0.25T Intermediate Frequency Furnace

0.5T Intermediate Frequency Furnace

Medium Frequency Furnace

2T Induction Melting Furnace

1T Induction Melting Furnace

500kg Induction Melting Furnace

250kg Induction Melting Furnace

Induction Melting Furnace

3 T Induction Melting Furnace

5T Induction Melting Furnace

1T One Belt Two Intermediate Frequency F

5T One Belt Two Intermediate Frequency F

3T One Belt Two Intermediate Frequency F

2T One Belt Two Intermediate Frequency F

5T Parallel Intermediate Frequency Furna

5T Intermediate Frequency Furnace

5T Series Intermediate Frequency Furnace

3T Series Intermediate Frequency Furnace

2T Series Intermediate Frequency Furnace

1T Series Intermediate Frequency Furnace

0.5T Series Intermediate Frequency Furna

0.25T Series Intermediate Frequency Furn

1T Parallel Intermediate Frequency Furna

2T Parallel Intermediate Frequency Furna

0.5T Parallel Intermediate Frequency Fur