Sales hot line ( 24 hours service):+86 13015583380

E-Mail: firstfurnace@gmail.com

whatsapp:+86 13015583380

Adress: Luoxin Industrial Park, Luoyang, HenanLarge diameter steel pipe quen

Piston rod quenching and tempe

Grinding rod quenching and tem

High frequency induction heate

Quenching equipment for machin

Round steel end heating furnac

Steel pipe heat treatment prod

Square steel quenching and tem

Sucker rod quenching and tempe

Thickened petroleum steel pipe

Round steel quenching and temp

Steel pipe quenching and tempe

Steel plate quenching and temp

Induction Hardening Machine&nb

Flywheel ring gear high freque

The new type metal melting induction melting furnace is composed of crucible, furnace body, induction ring and base. The refractory plate at the bottom of the furnace base and crucible is made of refractory cement and high alumina sand, with iron wire as the skeleton. The upper part of the crucible is a circulating cooling water pipe. In the metal melting induction melting furnace of the present utility model, the circulating cooling water pipe in the upper part of the crucible adopts waste

Old induction loop. After the base of the furnace and the lower part of the crucible are made of refractory cement and high alumina sand, a refractory plate made of iron wire as a framework is used in place of asbestos plate, which has low cost and convenient maintenance. The upper part of the crucible uses circulating cooling water pipes to replace the existing special-shaped special refractory bricks, which can evenly cool the crucible, prevent lateral cracks from occurring in the crucible, and facilitate maintenance operations.

Therefore, the utility model has the advantages of low cost, convenient maintenance, uniform cooling, and no transverse cracks in the neck portion.

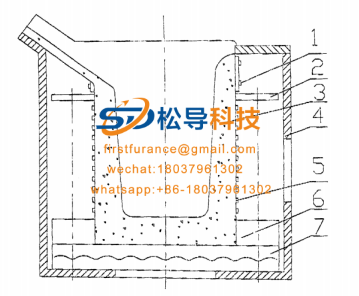

In the figure, 1. Cooling water pipe, 2. 2. Asbestos board; Crucible, 4. Furnace body, 5 induction coils, 6. Refractory board, 7. Base

detailed description

The following is further described with reference to the drawings: the crucible 3 is placed in the furnace body 4, the bottom of the crucible 3 is separated from the furnace body by a base 7, the lower periphery is a refractory plate 6, the base 7 and the refractory plate 6 are low in price and easy to buy The refractory cement is mixed with high alumina sand, with the iron wire as the skeleton. The middle periphery of the crucible is an induction coil 5 which is used for heating. The upper part of the crucible adopts the circulating cooling water pipe 1 made of waste induction coils to replace the existing special-shaped special refractory bricks. In this way, the crucible can be uniformly cooled, the crucible can be prevented from cracking laterally, and maintenance operations are convenient.

Iron induction furnace

Aluminum melting furnace

Copper melting furnace

Small steel melting furnace

Small induction melting furnace

Induction iron furnace

3T intermediate frequency iron melting f

0.25T Intermediate Frequency Furnace

0.5T Intermediate Frequency Furnace

Medium Frequency Furnace

2T Induction Melting Furnace

1T Induction Melting Furnace

500kg Induction Melting Furnace

250kg Induction Melting Furnace

Induction Melting Furnace

3 T Induction Melting Furnace

5T Induction Melting Furnace

1T One Belt Two Intermediate Frequency F

5T One Belt Two Intermediate Frequency F

3T One Belt Two Intermediate Frequency F

2T One Belt Two Intermediate Frequency F

5T Parallel Intermediate Frequency Furna

5T Intermediate Frequency Furnace

5T Series Intermediate Frequency Furnace

3T Series Intermediate Frequency Furnace

2T Series Intermediate Frequency Furnace

1T Series Intermediate Frequency Furnace

0.5T Series Intermediate Frequency Furna

0.25T Series Intermediate Frequency Furn

1T Parallel Intermediate Frequency Furna

2T Parallel Intermediate Frequency Furna

0.5T Parallel Intermediate Frequency Fur