Sales hot line ( 24 hours service):+86 13015583380

E-Mail: firstfurnace@gmail.com

whatsapp:+86 13015583380

Adress: Luoxin Industrial Park, Luoyang, HenanLarge diameter steel pipe quen

Piston rod quenching and tempe

Grinding rod quenching and tem

High frequency induction heate

Quenching equipment for machin

Round steel end heating furnac

Steel pipe heat treatment prod

Square steel quenching and tem

Sucker rod quenching and tempe

Thickened petroleum steel pipe

Round steel quenching and temp

Steel pipe quenching and tempe

Steel plate quenching and temp

Induction Hardening Machine&nb

Flywheel ring gear high freque

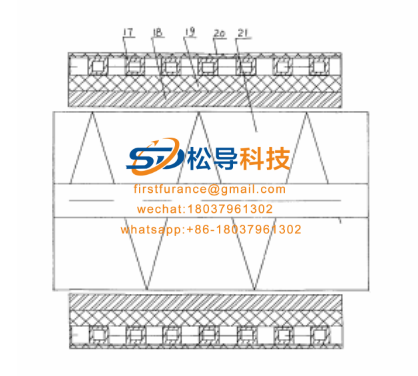

The inner spiral rotary induction heating furnace includes a spiral drum (21), and a heat insulation layer (18) is provided around the spiral drum (21), and a heat insulation layer (19) and a heat insulation layer (19) are provided outside the heat insulation layer (18). There is an intermediate frequency induction coil (17) outside, and an insulation case (20) is wrapped around the intermediate frequency induction coil (17). An intermediate frequency induction quenching and tempering production line equipped with an internal spiral rotary intermediate frequency induction heating furnace. An internal spiral rotary induction heating furnace (6) is installed between a spiral hot air drying furnace (5) and a quenching tank (7). An internal spiral rotary induction heating furnace (6) is also connected between the spiral hot air drying furnace (12) and the rotary cooling furnace (15). The utility model is energy-saving, time-saving, and does not require an oven. The utility model has the advantages of long service life and low maintenance cost, fast temperature rise and cooling, and short maintenance time. Induction heat treatment can improve the strength and life of parts.

http://www.songdaokeji.com/plus/list.php?tid=42

Iron induction furnace

Aluminum melting furnace

Copper melting furnace

Small steel melting furnace

Small induction melting furnace

Induction iron furnace

3T intermediate frequency iron melting f

0.25T Intermediate Frequency Furnace

0.5T Intermediate Frequency Furnace

Medium Frequency Furnace

2T Induction Melting Furnace

1T Induction Melting Furnace

500kg Induction Melting Furnace

250kg Induction Melting Furnace

Induction Melting Furnace

3 T Induction Melting Furnace

5T Induction Melting Furnace

1T One Belt Two Intermediate Frequency F

5T One Belt Two Intermediate Frequency F

3T One Belt Two Intermediate Frequency F

2T One Belt Two Intermediate Frequency F

5T Parallel Intermediate Frequency Furna

5T Intermediate Frequency Furnace

5T Series Intermediate Frequency Furnace

3T Series Intermediate Frequency Furnace

2T Series Intermediate Frequency Furnace

1T Series Intermediate Frequency Furnace

0.5T Series Intermediate Frequency Furna

0.25T Series Intermediate Frequency Furn

1T Parallel Intermediate Frequency Furna

2T Parallel Intermediate Frequency Furna

0.5T Parallel Intermediate Frequency Fur