Sales hot line ( 24 hours service):+86 13015583380

E-Mail: firstfurnace@gmail.com

whatsapp:+86 13015583380

Adress: Luoxin Industrial Park, Luoyang, HenanLarge diameter steel pipe quen

Piston rod quenching and tempe

Grinding rod quenching and tem

High frequency induction heate

Quenching equipment for machin

Round steel end heating furnac

Steel pipe heat treatment prod

Square steel quenching and tem

Sucker rod quenching and tempe

Thickened petroleum steel pipe

Round steel quenching and temp

Steel pipe quenching and tempe

Steel plate quenching and temp

Induction Hardening Machine&nb

Flywheel ring gear high freque

Rotary hood of aluminum electrolytic induction melting furnace for collecting flue gas of induction melting furnace in anode production workshop of electrolytic production .

Electrolytic induction melting furnace rotary anode assembly cover is aluminum electrolysis plant induction melting furnace collection means flue gas, the anode assembly is directly related to plant induction melting furnace successful or not flue gas treatment. Its role is to make the induction melting furnace flue gas in the anode assembly workshop not diffuse inside the workshop, collected by the device, and then discharged to the outside through the system. The traditional induction melting furnace flue gas of the anode assembly workshop adopts the natural exhaust type of the sunroof and the mechanical exhaust type of the axial fan installed on the side wall. These two types of exhaust effect are not good.

The purpose of the aluminum electrolytic induction melting furnace hood is to prevent the induction melting furnace flue gas from diffusing in the anode assembly workshop .

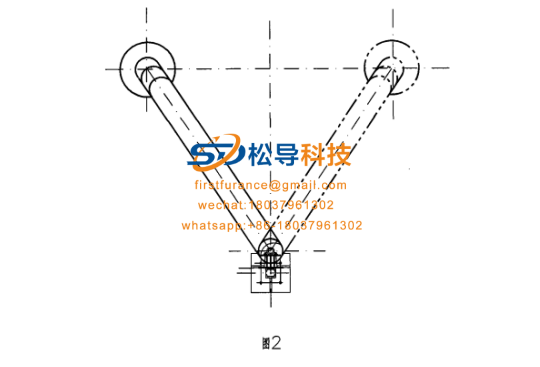

Reconstructed structure: an exhaust hood is provided at the end of the exhaust pipe, and a gyrator is provided at the other end of the exhaust pipe. The exhaust pipe is fixed on the support through an air pipe support. The bracket is a right-angled triangle bracket, and the short right-angled side of the right-angled triangle is a shaft. Both ends of the shaft are provided with an upper bearing and a lower bearing. The upper bearing and the lower bearing are fixedly connected to the steel column through the upper bearing and the lower bearing. An end of the exhaust pipe provided with a gyrator is fixed on a steel column through an air pipe bracket. The exhaust hood is a circular umbrella-shaped exhaust hood, and the opening of the circular umbrella-shaped exhaust hood faces downward. The diameter of the circular umbrella exhaust hood is 1000mm ~ 1600mm. The height of the circular umbrella exhaust hood is 800-1500mm from the operating surface. The height of the steel column is 4000 ~ 5000mm. The height of the exhaust pipe from the operating surface is 2000 ~ 3000mm. The diameter of the exhaust pipe is 400 ~ 600mm. The exhaust pipe rotates at 50 degrees. ~ 80. The induction melting furnace flue gas is collected and discharged from the anode assembly workshop. Since the exhaust hood in the device can be rotated and an exhaust hood is set near the induction melting furnace , the exhaust effect is very obvious, and it does not affect the requirements of process production.

BRIEF DESCRIPTION OF THE DRAWINGS

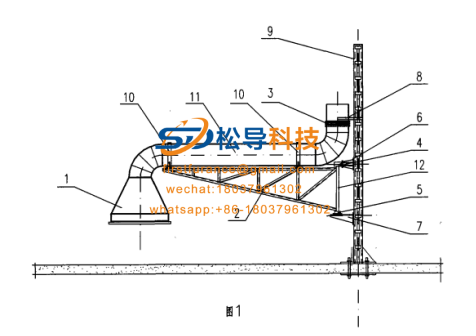

FIG. 1 is a schematic structural diagram of a rotary hood of an induction melting furnace .

FIG. 2 is a schematic diagram of a rotatable angle structure of the exhaust pipe.

In the picture 1 , the exhaust hood; 2, the bracket; 3, the gyrator; 4, the upper bearing; 5, the lower bearing; 6, the upper support; 7, the lower support;

8. Duct support; 9. Steel column; 10. Duct support; 11. Exhaust duct; 12. Shaft. detailed description

Structure composed of: the exhaust duct 11 is provided with a hood-terminal 1 , the exhaust pipe 11 and the other end is provided with a turning device 3, the central exhaust pipe II straight tube sections fixed to the holder 2, the holder 2 is fixed to the steel column 9, the exhaust pipe II is fixed on the bracket 2 through the duct support 10, the bracket 2 is a right-angled triangle bracket, the short right-angle side of the right-angled triangle is the shaft 12, and the upper end of the shaft 12 is provided with an upper bearing 4 and a lower bearing 5 The upper bearing 4 and the lower bearing 5 are fixedly connected to the steel column 9 through the upper support 6 and the lower support 7. The end of the exhaust pipe 11 provided with the rotator 3 is fixed on the steel column 9 through the air pipe bracket 8. The above-mentioned exhaust hood 1 may adopt a circular umbrella-shaped exhaust hood, with the opening of the circular umbrella-shaped exhaust hood facing downward, the diameter of the circular-shaped exhaust hood is 1000 mm to 1600 mm, and the height of the circular-shaped exhaust hood from the operating surface is 800 ~ 1500mm; steel column 9 is 4000 ~ 5000mm; exhaust pipe II is 2000 ~ 3000mm away from the operating surface; exhaust pipe II is 400 ~ 600mm in diameter; exhaust pipe rotation angle is 50. ~ 80. The flue gas is discharged from the workshop by the exhaust hood 1 through the exhaust pipe 11 . The exhaust hood 1 and the exhaust pipe 11 can realize the exhaust hood and the exhaust pipe through the combined action of the bracket 2, the upper bearing 4, the lower bearing 5, the shaft 12, the support 6, the lower support 7, and the gyrator 3. from the rotation without affecting the production process.

http://www.songdaokeji.com/plus/list.php?tid=22

http://www.songdaokeji.com

Iron induction furnace

Aluminum melting furnace

Copper melting furnace

Small steel melting furnace

Small induction melting furnace

Induction iron furnace

3T intermediate frequency iron melting f

0.25T Intermediate Frequency Furnace

0.5T Intermediate Frequency Furnace

Medium Frequency Furnace

2T Induction Melting Furnace

1T Induction Melting Furnace

500kg Induction Melting Furnace

250kg Induction Melting Furnace

Induction Melting Furnace

3 T Induction Melting Furnace

5T Induction Melting Furnace

1T One Belt Two Intermediate Frequency F

5T One Belt Two Intermediate Frequency F

3T One Belt Two Intermediate Frequency F

2T One Belt Two Intermediate Frequency F

5T Parallel Intermediate Frequency Furna

5T Intermediate Frequency Furnace

5T Series Intermediate Frequency Furnace

3T Series Intermediate Frequency Furnace

2T Series Intermediate Frequency Furnace

1T Series Intermediate Frequency Furnace

0.5T Series Intermediate Frequency Furna

0.25T Series Intermediate Frequency Furn

1T Parallel Intermediate Frequency Furna

2T Parallel Intermediate Frequency Furna

0.5T Parallel Intermediate Frequency Fur