Sales hot line ( 24 hours service):+86 13015583380

E-Mail: firstfurnace@gmail.com

whatsapp:+86 13015583380

Adress: Luoxin Industrial Park, Luoyang, HenanLarge diameter steel pipe quen

Piston rod quenching and tempe

Grinding rod quenching and tem

High frequency induction heate

Quenching equipment for machin

Round steel end heating furnac

Steel pipe heat treatment prod

Square steel quenching and tem

Sucker rod quenching and tempe

Thickened petroleum steel pipe

Round steel quenching and temp

Steel pipe quenching and tempe

Steel plate quenching and temp

Induction Hardening Machine&nb

Flywheel ring gear high freque

In addition to surface hardening, what other applications do induction heating furnaces have?

In addition to surface hardening, induction heating furnaces are also used in the following aspects:

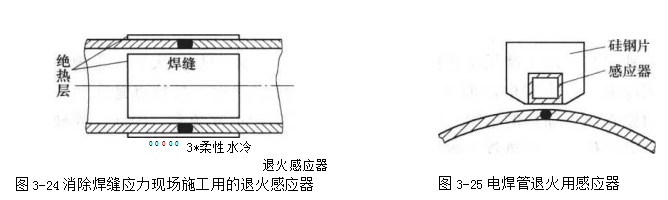

(1) Stress relief and normalizing Figure 3-24 shows a flexible water-cooled coil that wraps the butt weld of a casing, and performs stress relief or annealing on the welding position. Figure 3-25 shows a linear inductor equipped with silicon steel sheets for annealing the longitudinal continuous welds of butt-welded pipes. The linear inductor heats the weld to above the temperature, so that the structure is recrystallized. Both ends of the tractor's high-pressure tubing are flared (20 steel), and induction normalizing is also used to restore the grains at the head of the shovel to normal.

(2) Pipes for penetration quenching and tempering oil well engineering, the outer diameter is between Φ60~Φ410, the wall thickness is between 5~16mm, and the 1000Hz intermediate frequency power supply has been used for penetration heating quenching and tempering (600 ~ 700 ℃) It is also carried out with an intermediate frequency power supply. The hardening and tempering of screw blanks has also been successfully used in diathermy furnaces.

(3) Induction heating is used to draw the tube. The diameter of the cold drawn tube is reduced in the cold state, and the reduction is small each time, in addition to annealing and pickling, the process is complicated. The use of induction heating to draw the tube can increase the diameter reduction by 1.5 times, and eliminate the annealing, pickling and other processes.

|

Iron induction furnace

Aluminum melting furnace

Copper melting furnace

Small steel melting furnace

Small induction melting furnace

Induction iron furnace

3T intermediate frequency iron melting f

0.25T Intermediate Frequency Furnace

0.5T Intermediate Frequency Furnace

Medium Frequency Furnace

2T Induction Melting Furnace

1T Induction Melting Furnace

500kg Induction Melting Furnace

250kg Induction Melting Furnace

Induction Melting Furnace

3 T Induction Melting Furnace

5T Induction Melting Furnace

1T One Belt Two Intermediate Frequency F

5T One Belt Two Intermediate Frequency F

3T One Belt Two Intermediate Frequency F

2T One Belt Two Intermediate Frequency F

5T Parallel Intermediate Frequency Furna

5T Intermediate Frequency Furnace

5T Series Intermediate Frequency Furnace

3T Series Intermediate Frequency Furnace

2T Series Intermediate Frequency Furnace

1T Series Intermediate Frequency Furnace

0.5T Series Intermediate Frequency Furna

0.25T Series Intermediate Frequency Furn

1T Parallel Intermediate Frequency Furna

2T Parallel Intermediate Frequency Furna

0.5T Parallel Intermediate Frequency Fur