Sales hot line ( 24 hours service):+86 13015583380

E-Mail: firstfurnace@gmail.com

whatsapp:+86 13015583380

Adress: Luoxin Industrial Park, Luoyang, HenanLarge diameter steel pipe quen

Piston rod quenching and tempe

Grinding rod quenching and tem

High frequency induction heate

Quenching equipment for machin

Round steel end heating furnac

Steel pipe heat treatment prod

Square steel quenching and tem

Sucker rod quenching and tempe

Thickened petroleum steel pipe

Round steel quenching and temp

Steel pipe quenching and tempe

Steel plate quenching and temp

Induction Hardening Machine&nb

Flywheel ring gear high freque

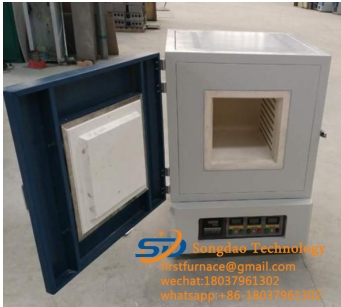

High-temperature muffle furnace is a general heating equipment, according to the shape can be divided into box furnace, tube furnace and furnace. It is a machine used for heating. How is the integrated heat transfer inside it?

In the heat exchange of the high-temperature muffle furnace, it is usually divided into three different temperature zones: furnace gas, furnace wall and heated metal. Among them, the temperature of the furnace gas is relatively high, followed by the temperature of the furnace wall, and the temperature of the heated metal is relatively low. In this way, between the furnace and the furnace wall, between the furnace gas and the metal, and between the furnace wall and the metal, heat exchange is carried out in the manner of radiation and convection, and there is also heat loss due to the heat conduction of the furnace wall.

1. Radiation heat transfer of high-temperature muffle furnace gas to metal After the heat radiated by the furnace gas is transferred to the furnace wall and the surface of the metal, part of it is attracted and the other part is reflected back. The reflected heat must pass through the furnace gas that fills the furnace, part of which is absorbed by the furnace gas, and the remaining part is radiated to the opposite furnace wall or metal, and it is radiated repeatedly.

2. Convective heat transfer of high-temperature muffle furnace gas to metal In the existing flame furnace, the temperature of the furnace gas is mostly in the range of 800℃-1400℃. When the furnace gas temperature is around 800°C, the effects of radiation and convection are almost equal. When the furnace gas temperature is higher than 800°C, the convective heat transfer decreases, while the radiative heat transfer increases sharply. For example, when the temperature of the open-hearth furnace gas in a steel mill reaches about 1800°C, the radiant part has reached about 95% of the total heat transfer.

3. The radiation heat transfer of the wall and top of the high-temperature muffle furnace to the metal is somewhat similar to the previous one, and it is also repeatedly radiated continuously. The difference is that the inner surface of the furnace wall also absorbs heat in a convective manner, and this heat is still transmitted in a radiant manner.

high temperature muffle furnace:https://songdaokeji.cn/

Iron induction furnace

Aluminum melting furnace

Copper melting furnace

Small steel melting furnace

Small induction melting furnace

Induction iron furnace

3T intermediate frequency iron melting f

0.25T Intermediate Frequency Furnace

0.5T Intermediate Frequency Furnace

Medium Frequency Furnace

2T Induction Melting Furnace

1T Induction Melting Furnace

500kg Induction Melting Furnace

250kg Induction Melting Furnace

Induction Melting Furnace

3 T Induction Melting Furnace

5T Induction Melting Furnace

1T One Belt Two Intermediate Frequency F

5T One Belt Two Intermediate Frequency F

3T One Belt Two Intermediate Frequency F

2T One Belt Two Intermediate Frequency F

5T Parallel Intermediate Frequency Furna

5T Intermediate Frequency Furnace

5T Series Intermediate Frequency Furnace

3T Series Intermediate Frequency Furnace

2T Series Intermediate Frequency Furnace

1T Series Intermediate Frequency Furnace

0.5T Series Intermediate Frequency Furna

0.25T Series Intermediate Frequency Furn

1T Parallel Intermediate Frequency Furna

2T Parallel Intermediate Frequency Furna

0.5T Parallel Intermediate Frequency Fur