Sales hot line ( 24 hours service):+86 13015583380

E-Mail: firstfurnace@gmail.com

whatsapp:+86 13015583380

Adress: Luoxin Industrial Park, Luoyang, HenanLarge diameter steel pipe quen

Piston rod quenching and tempe

Grinding rod quenching and tem

High frequency induction heate

Quenching equipment for machin

Round steel end heating furnac

Steel pipe heat treatment prod

Square steel quenching and tem

Sucker rod quenching and tempe

Thickened petroleum steel pipe

Round steel quenching and temp

Steel pipe quenching and tempe

Steel plate quenching and temp

Induction Hardening Machine&nb

Flywheel ring gear high freque

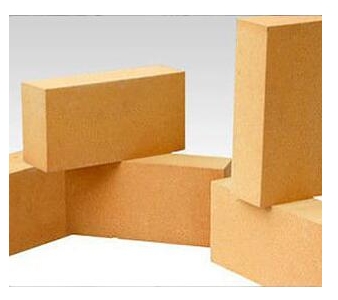

Clay refractory bricks for blast furnace

Clay refractory bricks for blast furnaces should be made of refractory clay for the lining of blast furnace walls. Clay refractory bricks for blast furnaces are used for the throat, shaft, hearth, bottom of the small blast furnace lining and the furnace shaft of the large blast furnace.

Clay refractory bricks for blast furnace require high compressive strength of fireproof materials at room temperature, which can resist long-term work damage of recycled waste materials; small volume shrinkage under long-term work at high temperature is beneficial to maintaining the comprehensiveness of the furnace lining; low apparent porosity and Fe:O. The low water content can reduce the accumulation of the carbon plant in the vent hole and prevent the refractory bricks from swelling and loosening and being destroyed during the whole application process; low melting point substances are produced less. Clay refractory bricks for blast furnaces have better properties than ordinary clay bricks.

The cross-section spallation of clay refractory bricks for blast furnaces has requirements:

(1) When the total width of the spall does not exceed 0.25mm, the length is not limited;

(2) When the total spall width is 0.26~0.5mm, the length should not exceed 15mm;

(3) When the total width of the spall exceeds 0.50mm, it is forbidden.

The cross-sectional cracks of clay refractory bricks have requirements:

(1) When the total width of the spall does not exceed 0.25mm, the length is not limited;

(2) When the total spall width is 0.26~0.50mm, the length should not exceed 40mm;

(3) Spalling is prohibited when the total width exceeds 0.5mm.

Iron induction furnace

Aluminum melting furnace

Copper melting furnace

Small steel melting furnace

Small induction melting furnace

Induction iron furnace

3T intermediate frequency iron melting f

0.25T Intermediate Frequency Furnace

0.5T Intermediate Frequency Furnace

Medium Frequency Furnace

2T Induction Melting Furnace

1T Induction Melting Furnace

500kg Induction Melting Furnace

250kg Induction Melting Furnace

Induction Melting Furnace

3 T Induction Melting Furnace

5T Induction Melting Furnace

1T One Belt Two Intermediate Frequency F

5T One Belt Two Intermediate Frequency F

3T One Belt Two Intermediate Frequency F

2T One Belt Two Intermediate Frequency F

5T Parallel Intermediate Frequency Furna

5T Intermediate Frequency Furnace

5T Series Intermediate Frequency Furnace

3T Series Intermediate Frequency Furnace

2T Series Intermediate Frequency Furnace

1T Series Intermediate Frequency Furnace

0.5T Series Intermediate Frequency Furna

0.25T Series Intermediate Frequency Furn

1T Parallel Intermediate Frequency Furna

2T Parallel Intermediate Frequency Furna

0.5T Parallel Intermediate Frequency Fur