Sales hot line ( 24 hours service):+86 13015583380

E-Mail: firstfurnace@gmail.com

whatsapp:+86 13015583380

Adress: Luoxin Industrial Park, Luoyang, HenanLarge diameter steel pipe quen

Piston rod quenching and tempe

Grinding rod quenching and tem

High frequency induction heate

Quenching equipment for machin

Round steel end heating furnac

Steel pipe heat treatment prod

Square steel quenching and tem

Sucker rod quenching and tempe

Thickened petroleum steel pipe

Round steel quenching and temp

Steel pipe quenching and tempe

Steel plate quenching and temp

Induction Hardening Machine&nb

Flywheel ring gear high freque

How does one-time induction heating furnace quenching of large-diameter crown gears work?

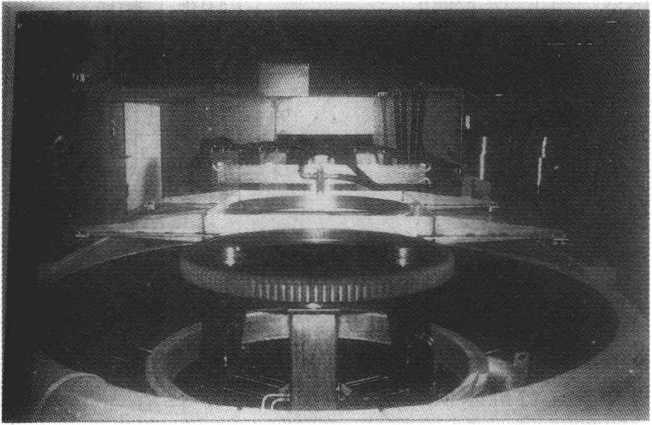

The large-diameter crown gear is quenched in an induction heating furnace at one time, and the processed gear diameter is 500 ~ 1600mm, the modulus is 6 ~ 14mm, and the hardening depth is 2 ~ 3mm below the gear root circle. Crown gear induction heating furnace and quenching device are shown in Figure 8-42.

Figure 8-42 Crown gear induction heating furnace and quenching device

The solid-state power supply has two levels of frequency and power, namely 1600kW/4kHz and 1200kW/8kHz. The selection of gear induction heating frequency depends on the modulus. After the large gear is induction heated, it falls into the quenching spray with a flow rate of 8000L/min, and the quenching solution contains additives. After the gear is quenched, return to the induction heating furnace to perform stress relief tempering. The typical production capacity, taking a gear with a diameter of lm and a module of 8mm as an example, is 10 pieces/h.

Iron induction furnace

Aluminum melting furnace

Copper melting furnace

Small steel melting furnace

Small induction melting furnace

Induction iron furnace

3T intermediate frequency iron melting f

0.25T Intermediate Frequency Furnace

0.5T Intermediate Frequency Furnace

Medium Frequency Furnace

2T Induction Melting Furnace

1T Induction Melting Furnace

500kg Induction Melting Furnace

250kg Induction Melting Furnace

Induction Melting Furnace

3 T Induction Melting Furnace

5T Induction Melting Furnace

1T One Belt Two Intermediate Frequency F

5T One Belt Two Intermediate Frequency F

3T One Belt Two Intermediate Frequency F

2T One Belt Two Intermediate Frequency F

5T Parallel Intermediate Frequency Furna

5T Intermediate Frequency Furnace

5T Series Intermediate Frequency Furnace

3T Series Intermediate Frequency Furnace

2T Series Intermediate Frequency Furnace

1T Series Intermediate Frequency Furnace

0.5T Series Intermediate Frequency Furna

0.25T Series Intermediate Frequency Furn

1T Parallel Intermediate Frequency Furna

2T Parallel Intermediate Frequency Furna

0.5T Parallel Intermediate Frequency Fur