Sales hot line ( 24 hours service):+86 13015583380

E-Mail: firstfurnace@gmail.com

whatsapp:+86 13015583380

Adress: Luoxin Industrial Park, Luoyang, HenanLarge diameter steel pipe quen

Piston rod quenching and tempe

Grinding rod quenching and tem

High frequency induction heate

Quenching equipment for machin

Round steel end heating furnac

Steel pipe heat treatment prod

Square steel quenching and tem

Sucker rod quenching and tempe

Thickened petroleum steel pipe

Round steel quenching and temp

Steel pipe quenching and tempe

Steel plate quenching and temp

Induction Hardening Machine&nb

Flywheel ring gear high freque

Billet online heating ( insulation) device

First, billet heating furnace, billet induction heating furnace, billet heating equipment overview

PLC automatic control system, domestic assembly, world-class technology, localized service, lowest price

1. The integrated design of the feeding and discharging mechanism, coil and power supply requires less infrastructure, workshop occupation and installation time.

2. Parallel intermediate frequency power supply design, AC voltage is converted into DC voltage by diode, and energy conversion efficiency is 96%.

3. The output power can be adjusted between 10% and 100%. All power ranges can maintain 0.96 power factor, and harmonic distortion is less polluted.

4, due to the short transmission distance of the power supply, the use of special insulation materials, series-connected power supply inverter measurement current small voltage high, medium frequency single consumption is very low.

5. Dynamically monitor the change of the load current of the series resonant coil, and timely control the output power of the power supply to ensure the heating temperature is stable.

6, other rich detection, self-diagnosis, alarm function and safety protection device.

7, the import of key components, the use of high-quality electrical components, domestic assembly; world-class technology, localization services and prices.

8. According to the size of the blank, different heating frequency is selected to save power consumption; the coil is adapted to the diameter of the billet to be 1 times wider.

9. The embedded operation panel displays the running status of the machine and is used for fault diagnosis; manual or man-machine interface operation mode can be selected.

10, standard power supply built-in closed internal circulation distilled water cooling system, you can choose the inner water system of the coil or provide a complete set of water cooling solutions.

11. The pneumatic or variable frequency nip roller feeding mechanism can be selected; the quick extraction and discharging system can eliminate the bonding mechanism and can be equipped with a temperature sorting system.

Second , billet parameters and process requirements

2.1、Billet size 130x130 mm , 12 m , Billet head temperature: surface 940 °C – core 1030 °C – average 960 °C

2.2、 Billet tail temperature: Surface 925 °C – Core 985 °C – Average 938 °C

2.3、 Elapsed time from start to finish: 109 s – speed 0.11 m/s – output 51.5 t/h

2.4 150x150 mm 12 m

2.5、Billet head temperature: Surface 949 °C – Core 1065 °C – Average 975 °C

2.6、Billet tail temperature: Surface 933 °C – Core 1005 °C – Average 948 °C

2.7、 Elapsed time from start to finish: 145 s – speed 0.083 m/s – output 51.8 t/h

2.8、 The first mill is required to have the same temperature at the head and tail of the first mill, and the minimum working temperature is 1050 °C:

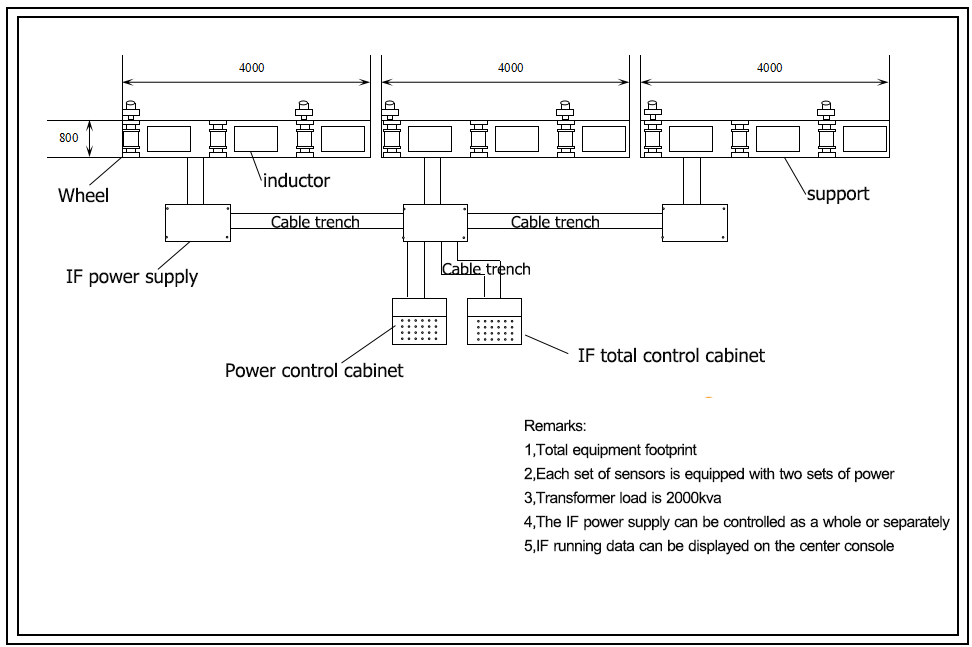

Third, Determination of the plane arrangement of the power frequency and power:

According to the maximum size of the billet 150x150 mm 12 m, the calculated frequency range is in the range of 1600 Hz to 600 Hz, and the frequency of the furnace is determined to be 1000 Hz.

Calculated according to the maximum billet 150x150 mm 12 m weight (2080 kg) and productivity (145 seconds / piece), the required heating power is up to 1500 kw, which can meet all billet heating and insulation.

Fourth, Device range and function description:

1. Equipment range is shown in the table below

|

Serial number |

content |

Quantity |

Remarks |

|

|

1 |

12-pulse rectifier transformer 1500 KVA |

1 set |

|

|

|

2 |

Connecting copper bars |

|

|

|

|

2 |

Thyristor intermediate frequency power supply KGPS-1 5 00/1 |

2 sets |

|

|

|

|

|

|

|

|

|

3 |

Induction heater |

1 set |

|

|

|

3.1 |

GTR130 (slab size 130x130mm12m) |

1 set |

|

|

|

|

GTR150 (slab size 150x150mm12m) |

|

|

|

|

4 |

Induction heater bed |

1 set |

|

|

|

5 |

Feeding device |

1 set |

|

|

|

6 |

Discharge device |

1 set |

|

|

|

7 |

Power control cabinet |

1 set |

|

|

|

8 |

Temperature control system (infrared temperature measurement and control instrument) |

1 set |

|

|

|

8.1 |

PLC center console |

1 set |

||

|

8.2 |

Programmable Controllers |

1 set |

||

|

8.3 |

LCD screen |

1 set |

||

|

8.4 |

Double colorimetric infrared thermometer (Xi'an Ruiguang) |

1 set |

||

|

8.5 |

Photoelectric alarm switch |

1 set |

||

|

8.6 |

Control cabinet |

1 set |

||

|

A, comprehensive parameters |

||

|

Serial number |

project |

Parameter requirement |

|

1 |

Power supply |

1 5 00kw / 3 phase 6 veins |

|

2 |

Number of rectifiers |

12 veins |

|

3 |

Inverter |

SCR parallel inverter |

|

4 |

Rated frequency |

Above 1000Hz |

|

5 |

Line voltage |

660V |

|

6 |

IF voltage |

1600V |

|

7 |

Start success rate |

100% |

|

8 |

Power factor |

Greater than 0.9 2 |

|

9 |

Outlet heating temperature |

1150 ° C |

|

10 |

Heating temperature rise power consumption |

≤ 60 ±5% kW.h/t |

|

11 |

heating time |

145 seconds / root |

|

|

|

|

|

B. Heat exchange cooling water system parameters |

||

|

Serial number |

project |

parameter |

|

1 |

Inlet pressure |

0.2-0.4MPa |

|

2 |

Inlet temperature |

5-35 ° C |

|

3 |

Effluent temperature |

<55°C |

The rectifier transformer is a special transformer that provides rectification power for the intermediate frequency electric furnace. The transformer (full copper core oil immersion type) has the characteristics of strong overload capability, less harmonic current and good cooling effect.

Rectifier transformer technical parameters:

|

model: |

Overload type ZS11- 1500 KVA/10KV /660v |

|

Rated Capacity: |

Se= 1500kva |

|

Primary voltage: |

U1=10000V±5% 6- phase 12-pulse 50HZ |

|

Primary current: |

I1= 86 A |

|

Secondary voltage: |

U2= 660Vx2 |

|

Secondary current: |

I2= 650x2A |

|

Pressure regulation method: |

Three-speed manual non-excitation regulator |

|

Connection group: |

D/d. -yn11 |

|

Impedance voltage: |

Z75o=6.5% |

|

effectiveness: |

≥ 97% |

1500kw intermediate frequency power supply main components and manufacturers

|

Serial number |

name |

Specification model |

Quantity |

Manufacturer |

|

1 |

Rectifier thyristor |

KP 1000 A, 20 00V |

12 |

Hubei Xiangfan Taiji |

|

2 |

Universal circuit breaker |

DW15- 1600 A |

2 |

Zhejiang Zhaoyu |

|

3 |

Thyristor radiator |

SS14-BL |

6 |

Wenzhou Love |

|

4 |

Absorption capacitor |

0.47uF2000V |

12 |

State-owned 794 factory |

|

5 |

Absorption resistor |

150W15Ω |

12 |

Suzhou Hengde Telecommunications |

|

6 |

Flat wave reactor |

3mH |

2 |

self made |

|

7 |

Line reactor |

Φ100*16 |

6 |

self made |

|

8 |

meter |

Type 42 |

6 |

People's Electric, Shanghai Pujiang |

|

9 |

Copper |

|

|

Copper |

|

10 |

Inverter thyristor |

KK 2000 A, 2 0 00V |

8 |

Hubei Xiangfan Taiji |

|

11 |

Thyristor radiator |

SS15-BL |

4 |

Wenzhou Love |

|

12 |

Inverter absorption capacitor |

0.47uF2000V |

8 |

State-owned 794 factory |

|

13 |

Inverter absorption resistor |

300W15Ω |

8 |

Suzhou Hengde Telecommunications |

|

14 |

Resonant capacitor |

RFM 1.2 - 2 000- 0.5 S |

10 |

Shenghe of Zhejiang Construction |

|

15 |

Hydraulic station |

|

|

Shanxi Yuci |

Iron induction furnace

Aluminum melting furnace

Copper melting furnace

Small steel melting furnace

Small induction melting furnace

Induction iron furnace

3T intermediate frequency iron melting f

0.25T Intermediate Frequency Furnace

0.5T Intermediate Frequency Furnace

Medium Frequency Furnace

2T Induction Melting Furnace

1T Induction Melting Furnace

500kg Induction Melting Furnace

250kg Induction Melting Furnace

Induction Melting Furnace

3 T Induction Melting Furnace

5T Induction Melting Furnace

1T One Belt Two Intermediate Frequency F

5T One Belt Two Intermediate Frequency F

3T One Belt Two Intermediate Frequency F

2T One Belt Two Intermediate Frequency F

5T Parallel Intermediate Frequency Furna

5T Intermediate Frequency Furnace

5T Series Intermediate Frequency Furnace

3T Series Intermediate Frequency Furnace

2T Series Intermediate Frequency Furnace

1T Series Intermediate Frequency Furnace

0.5T Series Intermediate Frequency Furna

0.25T Series Intermediate Frequency Furn

1T Parallel Intermediate Frequency Furna

2T Parallel Intermediate Frequency Furna

0.5T Parallel Intermediate Frequency Fur