Sales hot line ( 24 hours service): 18037961302

E-Mail: firstfurnace@gmail.com

whatsapp:+8618037961302

Adress: Luoxin Industrial Park, Luoyang, HenanLarge diameter steel pipe quen

Piston rod quenching and tempe

Grinding rod quenching and tem

High frequency induction heate

Quenching equipment for machin

Round steel end heating furnac

Steel pipe heat treatment prod

Square steel quenching and tem

Sucker rod quenching and tempe

Thickened petroleum steel pipe

Round steel quenching and temp

Steel pipe quenching and tempe

Steel plate quenching and temp

Induction Hardening Machine&nb

Flywheel ring gear high freque

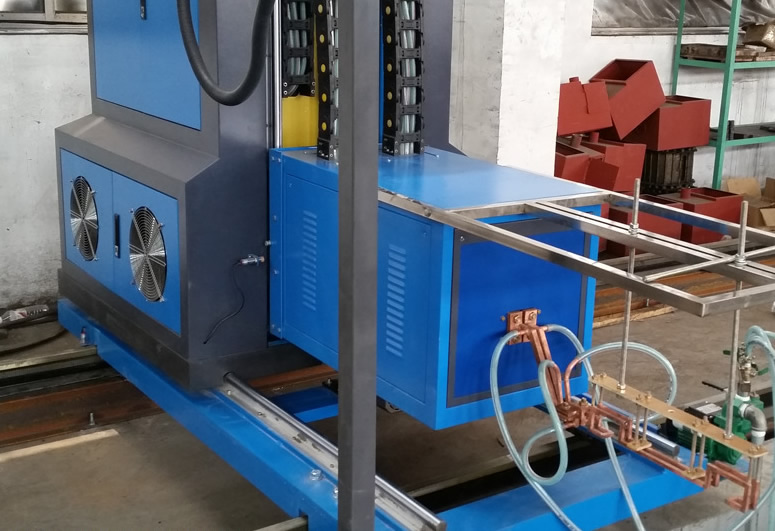

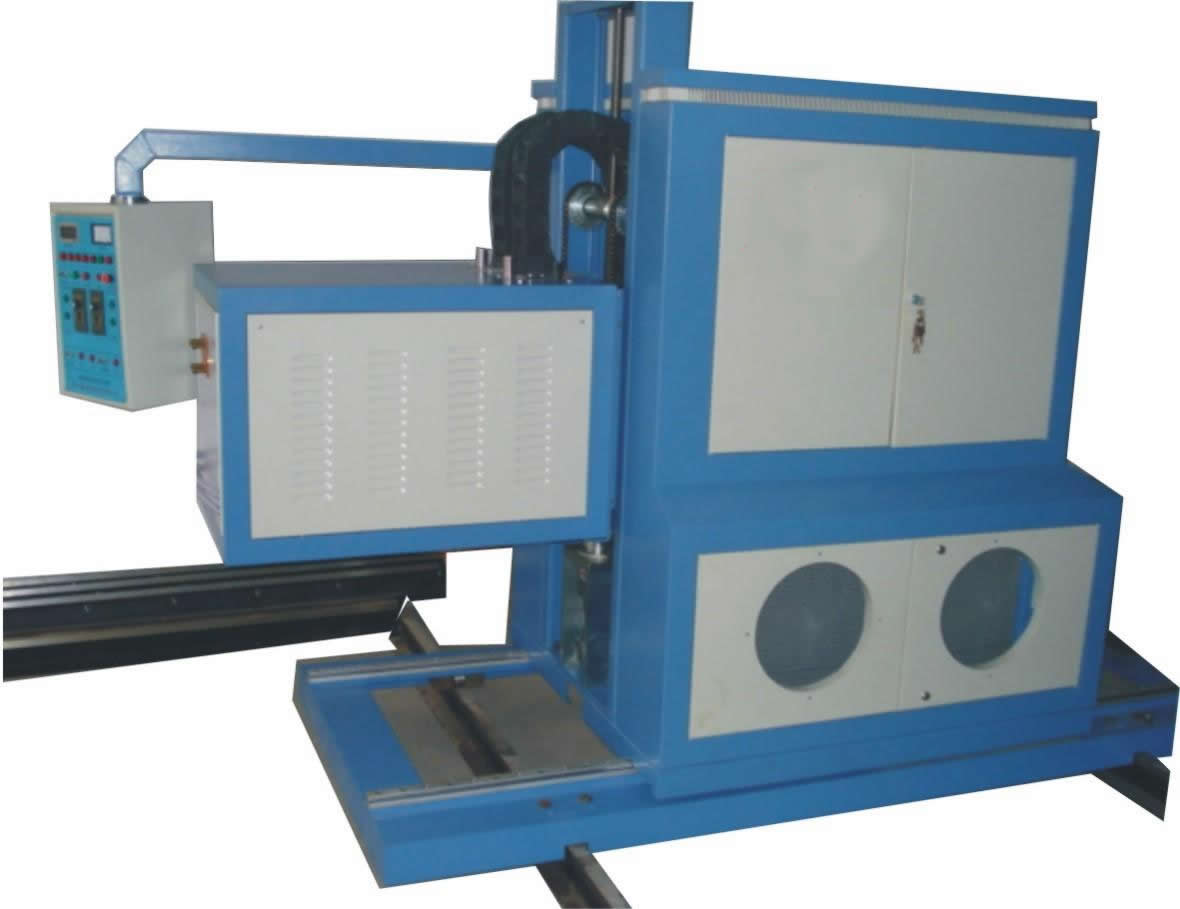

Quenching equipment for machine tool rails

Quenching equipment for machine tool rails

1. Selection method of quenching equipment for machine tool guide rails:

1. The power transformer, inductor, and water cooling system are uniformly designed and manufactured into a set of systems.

2. Machine tool guide rail quenching equipment has longitudinal movement (along the axis of the bed), advance and retreat movement perpendicular to the machine tool, and up and down movement.

3. Optional dual-frequency 10-15KHZ , 15-25KHZ dual-frequency power supply. To adapt to different bed surfaces.

2. The main components of quenching equipment for machine tool guide rails:

1. Super audio frequency induction heating power supply

2. Water-cooled unit

3. Sensor

4. Three-dimensional motion mechanism

5. Operation box

Third, the performance characteristics of the machine tool guide rail quenching equipment:

1. The high-frequency hardening layer is too shallow, and the intermediate-frequency hardening layer is too deep and easy to deform. The machine tool guideway quenching equipment is suitable for guideway quenching. And the quenching layer is moderate, the speed is fast, and the double guide rail is quenched at one time.

2. The control cabinet of the machine tool guide rail quenching equipment is integrated with the transformer cabinet, which is easy to install and flexible to move.

3. Comes with a cooling system, which solves the problems of long time to build a pool, inconvenience, and freezing in winter.

4. The structure of the sensor is simple and convenient, the gap is easy to adjust, and the guide wheel is positioned to avoid sparking.

5. Machine tool guide rail quenching equipment is especially suitable for larger, heavier and longer guide rails and bed surfaces, such as planer milling, planer, and large lathes. It is also suitable for quenching of various machine tool bed surfaces and other machine tool accessories.

6. With three-dimensional movement, it solves the hidden dangers of difficult, inconvenient, and long time for customers to make tooling.

Fourth, what are the methods for quenching machine tool rails?

Quenching of machine tool guide rails is a metal heat treatment process in which the guide rails are heated to an appropriate temperature and maintained for a period of time, and then immersed in a quenching medium for rapid cooling. Commonly used quenching media include brine, water, mineral oil, air, etc., and more water is used. Quenching can improve the hardness and wear resistance of metal workpieces, so it is widely used in various tools, molds, measuring tools and parts that require surface wear resistance (such as gears, rolls, carburized parts, etc.). Through quenching and tempering at different temperatures, the strength, toughness and fatigue strength of the metal can be greatly improved to meet different requirements. Quenching of the machine tool guide rail greatly improves the service life, wear resistance and damage resistance of the machine tool guide rail, thereby also improving the production efficiency of the machine tool to a certain extent.

5. How to automate the quenching of machine tool rails?

A new type of rail quenching special machine tool for surface heat treatment of machine tool rails. This machine combines the material and heat treatment requirements of machine tool rails, takes customer requirements as its own responsibility, and combines high-frequency surface quenching technology to overcome the difficulties of rail quenching and integrate it into mechanization and automation. In combination, the use of modular programming to control the quenching quality of the machine tool rails realizes the working principle technology that the entire operation can be realized without leaving the operating room .

Iron induction furnace

Aluminum melting furnace

Copper melting furnace

Small steel melting furnace

Small induction melting furnace

Induction iron furnace

3T intermediate frequency iron melting f

0.25T Intermediate Frequency Furnace

0.5T Intermediate Frequency Furnace

Medium Frequency Furnace

2T Induction Melting Furnace

1T Induction Melting Furnace

500kg Induction Melting Furnace

250kg Induction Melting Furnace

Induction Melting Furnace

3 T Induction Melting Furnace

5T Induction Melting Furnace

1T One Belt Two Intermediate Frequency F

5T One Belt Two Intermediate Frequency F

3T One Belt Two Intermediate Frequency F

2T One Belt Two Intermediate Frequency F

5T Parallel Intermediate Frequency Furna

5T Intermediate Frequency Furnace

5T Series Intermediate Frequency Furnace

3T Series Intermediate Frequency Furnace

2T Series Intermediate Frequency Furnace

1T Series Intermediate Frequency Furnace

0.5T Series Intermediate Frequency Furna

0.25T Series Intermediate Frequency Furn

1T Parallel Intermediate Frequency Furna

2T Parallel Intermediate Frequency Furna

0.5T Parallel Intermediate Frequency Fur