Sales hot line ( 24 hours service):+86 13015583380

E-Mail: firstfurnace@gmail.com

whatsapp:+86 13015583380

Adress: Luoxin Industrial Park, Luoyang, HenanLarge diameter steel pipe quen

Piston rod quenching and tempe

Grinding rod quenching and tem

High frequency induction heate

Quenching equipment for machin

Round steel end heating furnac

Steel pipe heat treatment prod

Square steel quenching and tem

Sucker rod quenching and tempe

Thickened petroleum steel pipe

Round steel quenching and temp

Steel pipe quenching and tempe

Steel plate quenching and temp

Induction Hardening Machine&nb

Flywheel ring gear high freque

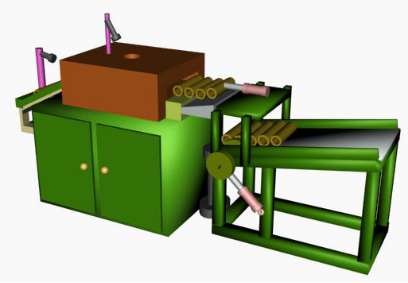

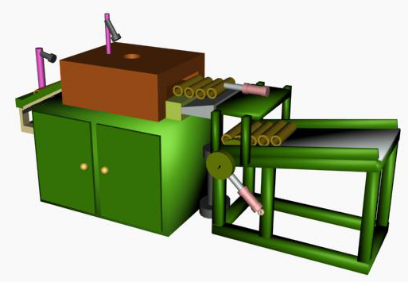

Titanium rod medium frequency induction heating equipment

Titanium rod medium frequency induction heating equipment

First, the medium frequency induction heating features:

1, fast heating, less oxidative decarburization

Since the principle of the intermediate frequency induction heating is electromagnetic induction, the heat is generated by the work itself, so the heating mode has a fast heating rate, little oxidation, high heating efficiency, and good process repeatability.

2, High degree of automation for fully automated unmanned operation

The automatic unloading and automatic discharge sorting device is selected, and the special control software developed by our company can be used to realize automatic unmanned operation.

3, Uniform heat and high temperature control accuracy

The heating is even, and the temperature difference of the heating core is small. Temperature control is precisely controlled by a temperature control system.

4, Easy replacement of induction furnace

Depending on the size of the machined workpiece, different sizes of induction furnaces can be configured. It can save energy and capital to the utmost. Each furnace body is designed with a water and electricity quick-change joint, which makes the furnace body replacement simple, fast and convenient.

5, Complete equipment protection, low failure rate, low maintenance rate, low loss rate

The complete set of equipment is equipped with water temperature, water pressure, over-current, over-pressure and lack of protection, and has upper and lower temperature alarm devices. The device is reliably protected in the event of a fault without damaging the components.

6, Low energy consumption and no pollution

High heating efficiency and limited energy consumption compared to other heating methods. The equipment meets environmental protection requirements and is non-polluting.

Second, technical requirements:

It is required to inductively heat the titanium bar material, the heating temperature is 900-1000 < C, the temperature is relatively uniform, and the temperature difference of the core watch does not exceed \ 10 < C.Automatic feeding is required, and automatic feeding is required. The beat is adjustable. The control system is more advanced and advanced. The surface of the titanium rod to be heated should not be subjected to too much friction, and the surface should be kept smooth. The specifications for heating the titanium rod are as follows:

Φ61, 68 〜 880 Φ78, 88, 98, 108, 118, 128 〜 850

Request beat: 1 minute / root

Third, the complete set of equipment:

1. Medium frequency power supply: KGPS-500KW/0.5KHZ

2, 500KW compensation capacitor cabinet

3. Medium frequency power supply KGPS-100KW/1KHZ

4, 100KW compensation capacitor cabinet

5, low voltage switch cabinet:

6. Heating furnace: GTRF-88 (heating ø61- ø88 material) GTRF-128 (heating ø98- ø128 material)

7, no coil equalizing furnace: GTRF-88 (average temperature ø61- ø88 material) GTRF-128 (average temperature ø98- ø128 material) 8, warming, temperature, holding furnace: GTRF-88 (average temperature ø61 - ø88 material) GTRF-128 (average temperature ø98- ø128 material)

9, automatic control of the operating system

10. Storage platform and pneumatic turning machine:

11, pneumatic feeder:

12, pneumatic pusher:

13, pneumatic discharge machine:

14. Two sorting institutions:

15, infrared thermometer

16. Water-water pure water cooler (FSS-100)

17, connecting cable and copper row

Iron induction furnace

Aluminum melting furnace

Copper melting furnace

Small steel melting furnace

Small induction melting furnace

Induction iron furnace

3T intermediate frequency iron melting f

0.25T Intermediate Frequency Furnace

0.5T Intermediate Frequency Furnace

Medium Frequency Furnace

2T Induction Melting Furnace

1T Induction Melting Furnace

500kg Induction Melting Furnace

250kg Induction Melting Furnace

Induction Melting Furnace

3 T Induction Melting Furnace

5T Induction Melting Furnace

1T One Belt Two Intermediate Frequency F

5T One Belt Two Intermediate Frequency F

3T One Belt Two Intermediate Frequency F

2T One Belt Two Intermediate Frequency F

5T Parallel Intermediate Frequency Furna

5T Intermediate Frequency Furnace

5T Series Intermediate Frequency Furnace

3T Series Intermediate Frequency Furnace

2T Series Intermediate Frequency Furnace

1T Series Intermediate Frequency Furnace

0.5T Series Intermediate Frequency Furna

0.25T Series Intermediate Frequency Furn

1T Parallel Intermediate Frequency Furna

2T Parallel Intermediate Frequency Furna

0.5T Parallel Intermediate Frequency Fur