Sales hot line ( 24 hours service):+86 13015583380

E-Mail: firstfurnace@gmail.com

whatsapp:+86 13015583380

Adress: Luoxin Industrial Park, Luoyang, HenanLarge diameter steel pipe quen

Piston rod quenching and tempe

Grinding rod quenching and tem

High frequency induction heate

Quenching equipment for machin

Round steel end heating furnac

Steel pipe heat treatment prod

Square steel quenching and tem

Sucker rod quenching and tempe

Thickened petroleum steel pipe

Round steel quenching and temp

Steel pipe quenching and tempe

Steel plate quenching and temp

Induction Hardening Machine&nb

Flywheel ring gear high freque

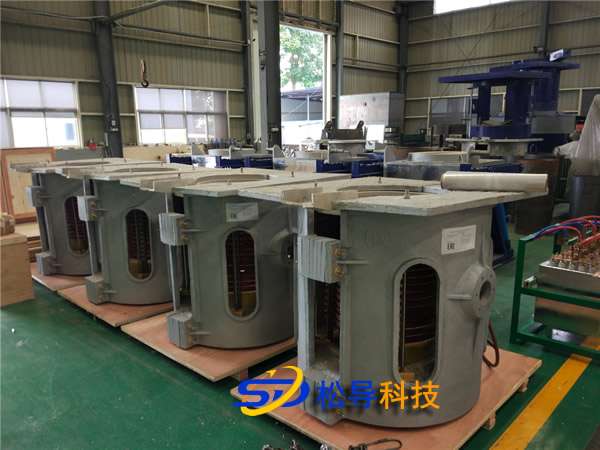

Energy-saving 0.5T induction melting furnace

Energy-saving 0.5T induction melting furnace

Equipment type :

Device parallel resonant frequency pulse power supply 12 and two steel coreless induction melting furnace and auxiliary systems required for normal operation of the equipment.

0.5 tons of steel induction melting furnace main parameters:

|

in frequency sense should melt Refining furnace |

Rated Capacity |

t |

0.5 |

|||

|

Maximum capacity |

t |

1 |

||||

|

Iron temperature |

<C |

1450~1 8 00 |

||||

|

Melting power consumption (hot furnace, molten steel) |

Kwh/t |

5 70 \ 5% in the case of pure melting . |

||||

|

Melting consumption (heating furnace,molten iron) |

Kwh/t |

5 60 \ 5% in the case of pure melting . |

||||

|

Melting rate (steel steel) |

h/t |

0.9 |

||||

|

cold but water |

Influent flow |

M3/h |

− 40 |

|||

|

Inlet pressure |

MPa |

0.3 |

||||

|

Inlet temperature |

<C |

+ 32 |

||||

|

Backwater temperature |

<C |

+ 52 |

||||

|

Tilting method |

|

Hydraulic tilting |

||||

|

|

||||||

|

whole flow change Pressure Device |

Product number |

ZS -type |

||||

|

Voltage combination |

10KV/380V/380V Secondary side Δ /Y double winding, star winding midpoint extraction |

|||||

|

Transformer capacity |

KVA |

1000kva (two shared) |

||||

|

Primary voltage |

KV |

10 \ 5% KV |

||||

|

Secondary voltage |

V |

380 〜 2 |

||||

|

Phase |

Primary side 3 phase ; secondary side 6 phase connected to intermediate frequency power supply cabinet |

|||||

|

frequency |

HZ |

50 |

||||

|

Connection group |

DdOY11 ( secondary side line voltage phase difference of 30< ) |

|||||

|

Short circuit impedance |

− |

9% |

||||

|

cooling method |

ONAN , cooling medium: 25thtransformer oil |

|||||

|

Pressure regulation method |

Automatic non-excitation voltage regulation , |

|||||

|

effectiveness |

− |

98%, |

||||

|

Executive standard |

JB/T8636-1997 "Power Converter Transformer" |

|||||

|

Rectifier transformer The rectifier transformer is used to reduce the primary high voltage to the input voltage suitable for the intermediate frequency power supply. The device uses a dedicated high-impedance oil-immersed self-cooling rectifier transformer, the model is ZS series. The primary voltage of the transformer is 10KV and the secondary voltage is 380V . The rectifier transformer is equipped with a gas relay and a oil temperature relay table, which can be interlocked with the high voltage cabinet. When the transformer has gas or oil temperature exceeding the standard, the high voltage input can be automatically cut off and an alarm is issued. |

||||||

|

|

||||||

|

in frequency Electricity source

|

rated power |

KW |

5 00 |

|||

|

DC voltage |

V |

102 4 |

||||

|

DC |

A |

488 |

||||

|

Number of commutating pulses |

pulse |

12 |

||||

|

cold but water |

Influent flow |

M3/h |

− 15 |

|||

|

Inlet pressure |

MPa |

0.25 |

||||

|

Inlet temperature |

<C |

+ 32 |

||||

|

Backwater temperature |

<C |

+ 42 |

||||

|

IF voltage |

V |

2400 |

||||

|

IF frequency |

Hz |

8 00 can be fine-tuned |

||||

|

Power factor |

C OSφ |

− 0.95 for any power usage |

||||

|

Inverter form |

|

Parallel inverter |

||||

|

noise |

dB |

85dB |

||||

|

Starting success rate |

|

100% |

||||

|

|

|

|

||||

|

|

|

|

||||

|

|

|

|

||||

|

|

|

|

|

|||

Iron induction furnace

Aluminum melting furnace

Copper melting furnace

Small steel melting furnace

Small induction melting furnace

Induction iron furnace

3T intermediate frequency iron melting f

0.25T Intermediate Frequency Furnace

0.5T Intermediate Frequency Furnace

Medium Frequency Furnace

2T Induction Melting Furnace

1T Induction Melting Furnace

500kg Induction Melting Furnace

250kg Induction Melting Furnace

Induction Melting Furnace

3 T Induction Melting Furnace

5T Induction Melting Furnace

1T One Belt Two Intermediate Frequency F

5T One Belt Two Intermediate Frequency F

3T One Belt Two Intermediate Frequency F

2T One Belt Two Intermediate Frequency F

5T Parallel Intermediate Frequency Furna

5T Intermediate Frequency Furnace

5T Series Intermediate Frequency Furnace

3T Series Intermediate Frequency Furnace

2T Series Intermediate Frequency Furnace

1T Series Intermediate Frequency Furnace

0.5T Series Intermediate Frequency Furna

0.25T Series Intermediate Frequency Furn

1T Parallel Intermediate Frequency Furna

2T Parallel Intermediate Frequency Furna

0.5T Parallel Intermediate Frequency Fur