Sales hot line ( 24 hours service):+86 13015583380

E-Mail: firstfurnace@gmail.com

whatsapp:+86 13015583380

Adress: Luoxin Industrial Park, Luoyang, HenanLarge diameter steel pipe quen

Piston rod quenching and tempe

Grinding rod quenching and tem

High frequency induction heate

Quenching equipment for machin

Round steel end heating furnac

Steel pipe heat treatment prod

Square steel quenching and tem

Sucker rod quenching and tempe

Thickened petroleum steel pipe

Round steel quenching and temp

Steel pipe quenching and tempe

Steel plate quenching and temp

Induction Hardening Machine&nb

Flywheel ring gear high freque

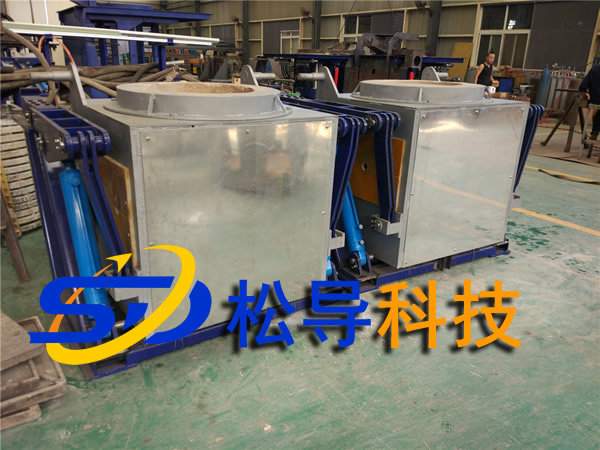

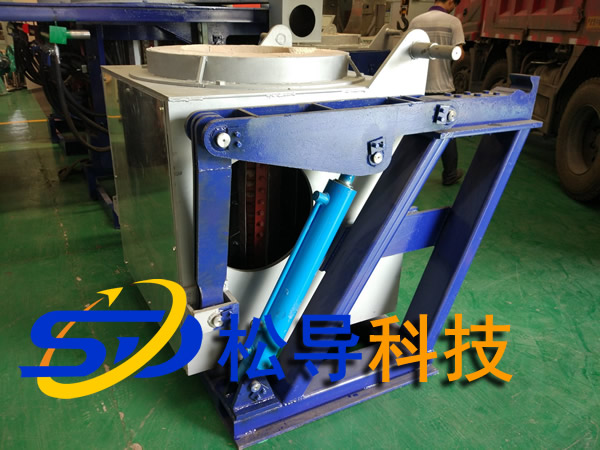

500kg fixed-point casting intermediate frequency furnace

First, description of Fixed point casting furnace

Equipment Overview: This product belongs to a new type of professional furnace. It is designed and manufactured by foreign technology. The unique hydraulic tilting rod linkage mechanism can always pour the metal solution into the material with small diameter during the whole process of melting and pouring out the molten metal. It is a choice of equipment for the production of metal powders and similar processes using a water (gas) atomization process.

Second , 0.5T / 250kw intermediate frequency coreless induction fixed point casting melting furnace main technical parameters

|

A, comprehensive parameters |

||

|

Serial number |

project |

parameter |

|

1 |

Power supply |

160kw , 250kw , 500kw , 1000kw |

|

2 |

Furnace rated capacity |

0.25T/0.5T/1T |

|

3 |

Rated frequency |

More than 8 00Hz |

|

4 |

Line voltage |

380 V |

|

C, furnace index |

||

|

Serial number |

project |

Parameter requirement |

|

1 |

Furnace shell structure |

Steel shell structure |

|

2 |

Furnace shell material |

45 # steel |

|

3 |

Yoke material |

Z11-0. 23 |

|

4 |

Yoke coverage |

8 5% |

|

5 |

Sensor copper tube material |

T2 pure copper 99.9 |

|

6 |

Hydraulic pump |

Double machine double pump |

|

7 |

Tilt angle |

0 to 95< |

Third, the fixed point furnace description

The furnace body part includes an induction heating coil, a structural body carbon steel , a yoke, an insulator, a heat-insulating material, a support frame, a fixed-point casting structure, and the like.

The fixed-point casting structure of the furnace body is installed on the supporting frame, and the furnace body and the hydraulic tilting furnace mechanism are designed according to the size of the atomizing tundish and the atomizing turret provided by the party A. The furnace body runs at a uniform speed, the height difference of the nozzle is small, and the liquid discharge is continuously stable. The running curve of the nozzle is fixed by the trajectory and optimized by the computer. The special curved template is used to guide the locking , so that the furnace body is uniformly and orderly discharged from the continuous liquid discharge to the fixed point. The tilting angle of the furnace body: 0゛ 95 < (0< refers to the horizontal position of the furnace mouth); the furnace has high stability of turning, and the positioning accuracy of the discharging port is high (the distance between the outlet and the leakage of the melting furnace is less than 50mm ) , and the pouring center changes. The error is small, the nozzle does not move back and forth when atomizing the steel, the precision of the fixed point casting is high, the front and back error does not exceed 30 mm, and the stability of the metal liquid flow is ensured. The maintenance and replacement of complete sets of equipment are modular in design, easy to maintain and easy to overhaul, greatly improving production efficiency.

Iron induction furnace

Aluminum melting furnace

Copper melting furnace

Small steel melting furnace

Small induction melting furnace

Induction iron furnace

3T intermediate frequency iron melting f

0.25T Intermediate Frequency Furnace

0.5T Intermediate Frequency Furnace

Medium Frequency Furnace

2T Induction Melting Furnace

1T Induction Melting Furnace

500kg Induction Melting Furnace

250kg Induction Melting Furnace

Induction Melting Furnace

3 T Induction Melting Furnace

5T Induction Melting Furnace

1T One Belt Two Intermediate Frequency F

5T One Belt Two Intermediate Frequency F

3T One Belt Two Intermediate Frequency F

2T One Belt Two Intermediate Frequency F

5T Parallel Intermediate Frequency Furna

5T Intermediate Frequency Furnace

5T Series Intermediate Frequency Furnace

3T Series Intermediate Frequency Furnace

2T Series Intermediate Frequency Furnace

1T Series Intermediate Frequency Furnace

0.5T Series Intermediate Frequency Furna

0.25T Series Intermediate Frequency Furn

1T Parallel Intermediate Frequency Furna

2T Parallel Intermediate Frequency Furna

0.5T Parallel Intermediate Frequency Fur