Sales hot line ( 24 hours service):+86 13015583380

E-Mail: firstfurnace@gmail.com

whatsapp:+86 13015583380

Adress: Luoxin Industrial Park, Luoyang, HenanLarge diameter steel pipe quen

Piston rod quenching and tempe

Grinding rod quenching and tem

High frequency induction heate

Quenching equipment for machin

Round steel end heating furnac

Steel pipe heat treatment prod

Square steel quenching and tem

Sucker rod quenching and tempe

Thickened petroleum steel pipe

Round steel quenching and temp

Steel pipe quenching and tempe

Steel plate quenching and temp

Induction Hardening Machine&nb

Flywheel ring gear high freque

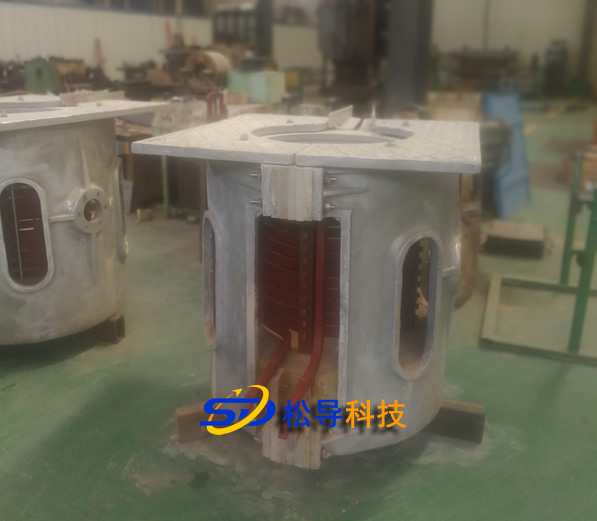

1.5T medium frequency induction melting furnace

First, the complete set of equipment:

The system includes: an electric furnace 1 .5 t; a 1500 KW SCR frequency power; a rectifier transformer owned 1 600 KVA (10KV / 2 * 750V); a control box furnace convenient operating. A total of one set.

Second, equipment technical parameters:

1, medium frequency power supply

|

Serial number |

project |

unit |

parameter |

Remarks |

|

1 |

Transformer capacity |

KVA |

1 600 |

all bronze |

|

2 |

Transformer primary voltage |

KV |

10 |

|

|

3 |

Transformer secondary voltage |

V |

2* 75 0 |

|

|

4 |

Rated melting power |

Kw |

150 0 |

|

|

5 |

Rated frequency |

Hz |

500 |

|

|

6 |

Rectifier string |

|

12 pulses |

|

|

7 |

Inverter |

|

SCR parallel |

|

|

8 |

Power conversion efficiency |

|

0.97 |

|

|

9 |

Power factor |

Cos〉 |

> 0.92 |

Under rated power |

|

10 |

Constant power output time |

|

> 90% |

Within the melting cycle |

|

11 |

Start success rate |

|

100% |

|

2, induction furnace body

|

Serial number |

project |

unit |

parameter |

Remarks |

|

1 |

Rated Capacity |

t |

1 .3 -1. 5 |

|

|

2 |

Induction ring diameter |

Mm |

7 6 0 |

Can be customized according to customer requirements |

|

3 |

Loading height |

Mm |

1100 |

Can be customized according to customer requirements |

|

4 |

Lining thickness |

Mm |

90-120 |

Can be customized according to customer requirements |

|

5 |

Rated operating temperature |

<C |

1580 |

Determined by the lining material |

|

6 |

Melting rate (1550 < C) |

t/h |

−1. 7-2T |

(hot state) |

|

7 |

power consumption |

KWh/T |

About 550-600 |

Error \5% |

Equipment configuration list and price

|

|

name |

model |

Simple configuration |

Quantity |

|

Power section |

12 pulse 800V IF power cabinet |

KGPS12-900-0.5S |

KP1000A/3600V platform KK1 5 00A/2500V platform Open DW15-1000A 2 sets All outlets with temperature monitoring |

1 set |

|

capacitor bank |

DR-900 |

Meet 1 5 00KW use |

1 set |

|

|

Furnace section |

Steel shell body |

GW- 1. 5 T |

The yoke height is 1.2 meters Induction ring inner diameter 7 6 0mm Waterway with temperature control Leaky furnace alarm |

1 set |

|

Reducer |

531 |

With bridge |

1 set |

|

|

Water cooled cable |

DH-SL-400 |

|

1 set |

|

|

Cooling Tower |

Power water cooling system |

BN- 10 0T |

|

1 set |

|

Furnace water cooling system |

BN- 5 0T (dual pump) |

|

1 set |

|

|

transformer |

|

|

Bring your own |

|

Iron induction furnace

Aluminum melting furnace

Copper melting furnace

Small steel melting furnace

Small induction melting furnace

Induction iron furnace

3T intermediate frequency iron melting f

0.25T Intermediate Frequency Furnace

0.5T Intermediate Frequency Furnace

Medium Frequency Furnace

2T Induction Melting Furnace

1T Induction Melting Furnace

500kg Induction Melting Furnace

250kg Induction Melting Furnace

Induction Melting Furnace

3 T Induction Melting Furnace

5T Induction Melting Furnace

1T One Belt Two Intermediate Frequency F

5T One Belt Two Intermediate Frequency F

3T One Belt Two Intermediate Frequency F

2T One Belt Two Intermediate Frequency F

5T Parallel Intermediate Frequency Furna

5T Intermediate Frequency Furnace

5T Series Intermediate Frequency Furnace

3T Series Intermediate Frequency Furnace

2T Series Intermediate Frequency Furnace

1T Series Intermediate Frequency Furnace

0.5T Series Intermediate Frequency Furna

0.25T Series Intermediate Frequency Furn

1T Parallel Intermediate Frequency Furna

2T Parallel Intermediate Frequency Furna

0.5T Parallel Intermediate Frequency Fur