Sales hot line ( 24 hours service):+86 13015583380

E-Mail: firstfurnace@gmail.com

whatsapp:+86 13015583380

Adress: Luoxin Industrial Park, Luoyang, HenanLarge diameter steel pipe quen

Piston rod quenching and tempe

Grinding rod quenching and tem

High frequency induction heate

Quenching equipment for machin

Round steel end heating furnac

Steel pipe heat treatment prod

Square steel quenching and tem

Sucker rod quenching and tempe

Thickened petroleum steel pipe

Round steel quenching and temp

Steel pipe quenching and tempe

Steel plate quenching and temp

Induction Hardening Machine&nb

Flywheel ring gear high freque

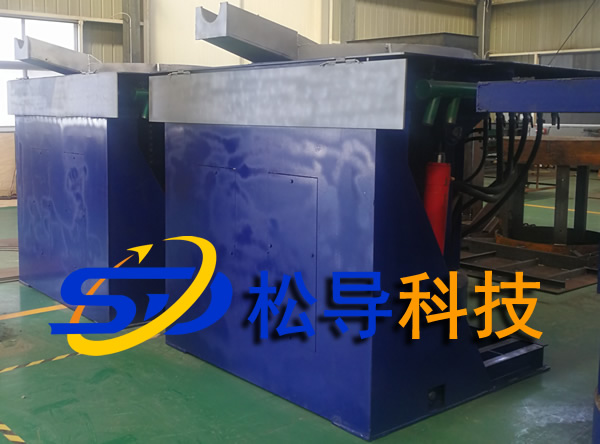

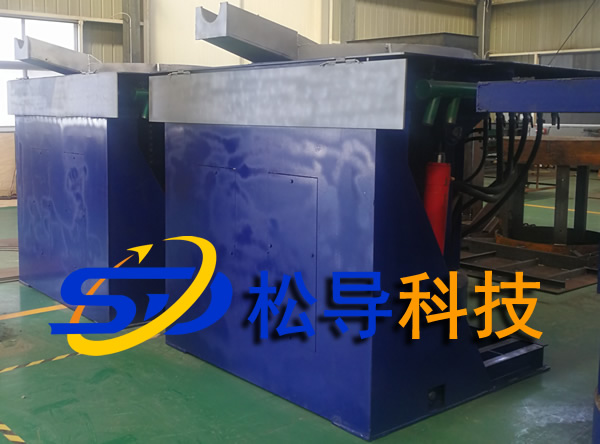

Steel shell intermediate frequency furnace

First, what is the steel shell medium frequency furnace ?

In the cylinder mode of turndown steel commonly known induction melting furnace IF steel furnace. The steel shell intermediate frequency furnace mainly includes: closed furnace frame, inductor coil, yoke, furnace cover, dust removal system, tilting oil cylinder, furnace rotating oil cylinder, high pressure carbonless rubber hose, furnace mouth and furnace bottom casting fixed material, full set of stainless steel Water distributor, return water collector, clamp, stainless steel water inlet and outlet, etc.

Second, steel shell intermediate frequency furnace price selection

|

|

Steel shell intermediate frequency furnace price |

|||||||

|

Power |

Line voltage |

Melting furnace |

Water Consumption |

power consumption |

Voltage |

capacity |

Total price |

|

|

GWG -0.5T |

400 |

660 |

0.5 |

10 |

720 |

800 |

0.5 |

Total: ¥ 148800 |

|

GWG -0.75T |

6 00 |

660 |

0.9 |

12 |

630 |

2700 |

0.75 |

Total: ¥ 1 6 8800 |

|

GWG -1 T |

800 |

380- 660 |

1 |

18 |

630-600 |

1400-2500 |

1 |

Total: ¥ 221,000 |

|

GWG -1.5T |

1200 |

380- 660 |

1.5 |

twenty two |

630-600 |

1400-2500 |

1.5 |

Total: ¥ 2 30 000 |

|

GWG -2T |

1 6 00 |

380- 660 |

2 |

28 |

600-550 |

1400-2500 |

2 |

Total: ¥ 361500 |

|

GWG -3T |

2000 |

660 - 1000 |

3 |

35 |

600-530 |

2300-5000 |

3 |

Total: ¥ 447,000 |

|

GWG -5T |

3000 |

660 - 1000 |

5 |

45 |

600-530 |

2300-5000 |

5 |

Total: ¥ 643000 Yuan |

|

GWG -6T |

3500 |

660 - 1000 |

6 |

50 |

600-530 |

2500-5000 |

6 |

Total: ¥ 7 43000 Yuan |

|

GWG -7T |

4000 |

660 - 1000 |

7 |

55 |

600-530 |

2500-5000 |

7 |

Total: ¥ 8 43000 Yuan |

|

GWG -8T |

5000 |

660 - 1000 |

8.5 |

65 |

600-530 |

2700-5000 |

10-15 |

Total: ¥ 940000 |

Third, steel shell intermediate frequency furnace body structure selection method ?

1, intermediate frequency furnace steel channel frame structure enclosed, easy maintenance, overhaul; channel welded become the basic structure of the hob, the overall structure is simple, sturdy, large furnace inclination of 95 degrees.

2, the platform surface knot frequency furnace refractory steel, the protection of the furnace more fully, the furnace platform is not deformed.

3 , steel shell medium frequency furnace welding steel structure, equipped with appropriate support and clamping parts to fix the induction furnace coil and yoke; the upper part of the induction furnace is detachable, so it is more convenient to replace the coil.

4 , heavy-duty steel members on both sides of the steel shell intermediate frequency furnace pillars, which become the solid support of the furnace body, provide the hydraulic tilting axis, and the shaft center moves outward and moves up. Ensure that the trajectory of the tapping nozzle is small, reduce the energy loss of the tapping water, and facilitate the automatic and direct connection of the molten steel to the molten steel.

5, a steel furnace IF induction coil and durable solid oxygen-free copper Laid guide tube assembly. The water-cooled coil and the effective coil are integrally wound by a copper tube. The non-segmented induction coil is strictly insulated between two adjacent copper tubes and adopts advanced segmentation technology. An insulating sheet is implanted between adjacent induction coils, and the coil is insulated. After the paint is sprayed, it becomes a complete structure and is pressed by the upper and lower steel structures in the furnace body, and the overall structure is firm and has no deformation problem. The steel shell medium frequency furnace coil has a proper number of turns, and can obtain large electric efficiency. The copper tube of the induction coil is made of medium-aluminum copper, which has an purity of 0.99 and a conductivity of more than 100. The coil is cooled by a plurality of water channels. Water, evenly distributed. The outside of the coil is tightly wound with an insulating material. The arc-shaped insulating spacers at the same time ensure uniform coil spacing and facilitate moisture discharge.

6, steel furnace IF induction coil insulating paint imported porcelain paint, spray and bake after five times, you can reach Class H insulation class.

7, intermediate frequency furnace steel yokes evenly force the bolt to the merger, and the coil providing a large holding force, ensure a long working life of the lining. The yoke is made of cold-rolled oriented silicon steel sheet with a thickness of 0.35mm . The tolerance of the shearing edge of the silicon steel sheet after processing is <±0.1mm . The bending of the steel shell intermediate frequency furnace is assembled. The parallelism ensures the coil and the yoke arc. Contact, fit. At the same time, multiple sets of yoke fastening devices are firm and reliable, easy to assemble, disassemble, adjust and repair, and evenly distributed along the circumference ( error ≤ 0.5) ; the yoke and the gasket between the coils are multi-layer high-quality insulating materials, including multiple layers. Mica board, multi-layer ceramic fiber board.

8, the top and bottom steel frequency furnace with molded insulation panel and short ring.

9, intermediate frequency furnace steel furnace leakage protection safe and reliable system, when the molten steel is about to penetrate or invade permeable refractory material and a coil automatically cut off power and alarm. The leak protection system is an important part of the entire furnace protection system.

Fourth, what are the advantages of steel shell intermediate frequency furnace ?

1) Rugged and elegant, especially for large-capacity furnaces, it requires a strong rigid structure. From the safety point of the tilting furnace, try to use steel shell intermediate frequency furnace .

2) The yoke made of silicon steel sheet shields and emits magnetic lines of force generated by the induction coil, reduces magnetic leakage, improves thermal efficiency, increases production, and saves energy by about 5%-8% .

3) The presence of the furnace cover reduces heat loss and increases the safety of the equipment.

4) Long service life, steel shell medium frequency furnace due to less magnetic leakage, equipment life is much higher than aluminum shell furnace. The normal service life is generally more than 10 years.

5) IF steel furnace safety performance much better than the aluminum furnace, aluminum melting furnace in the time due to high temperature, weight, aluminum is easily deformed, poor security. The steel shell intermediate frequency furnace uses a hydraulic tilting furnace, which is safe and reliable.

5. What are the main uses of steel shell intermediate frequency furnaces ?

IF steel melting furnace is mainly applied to steel, iron, copper, aluminum and alloys, having a high melting efficiency, energy-saving effect, a uniform metal composition, burning small, quick temperature rise, easy to control temperature, etc., suitable for all melting metals.

6. What is the role of the yoke in the steel shell intermediate frequency furnace ?

The yoke is a yoke made of a stack of silicon steel sheets. It is uniformly and symmetrically divided around the induction coil. Its function is to constrain the magnetic flux leakage of the induction coil to improve the efficiency of the induction and increase the magnetic shielding. The heat generation of metal members such as the hob also serves to reinforce the inductor.

The steel shell medium frequency furnace body has a built-in yoke, and the yoke shield can reduce the magnetic flux leakage, prevent the furnace body from heating and improve the efficiency. At the same time, the yoke acts as a support for fixing the induction coil, so that the furnace body achieves high strength and low noise.

Seven, intermediate frequency furnace steel yoke temperature is too high what is the reason?

The yoke redness is a common failure phenomenon in the operation of the intermediate frequency power supply. First check if there is any problem with the cooling water system, check whether the red yoke inlet and outlet water is normal, and whether the pipeline is aging or leaking. If it is normal, check the following aspects.

(1) The yoke of the intermediate frequency power supply is aging, and the interlayer insulating coating is severely corroded. For this, the silicon steel sheet can be opened for surface coating treatment.

(2) The yoke is adhered to the molten steel (iron filings), and the yoke can be polished to remove the adhered iron filings.

(3) Check the thickness of the bottom of the furnace. If the bottom of the furnace is too thick, it will cause the yoke to heat up and become red.

(4) The temperature of the circulating water inlet water is too high, and the water temperature inside the yoke circulation system is too high to generate gas. Since the gas cannot be discharged, the circulating water cannot circulate, causing the temperature to rise.

( 5 ) The circulating water pressure becomes smaller, or after the waterway is changed, the waterway becomes more or the water pipe becomes larger, and the water flow of the other circuits becomes larger, causing the yoke water flow to become smaller.

Iron induction furnace

Aluminum melting furnace

Copper melting furnace

Small steel melting furnace

Small induction melting furnace

Induction iron furnace

3T intermediate frequency iron melting f

0.25T Intermediate Frequency Furnace

0.5T Intermediate Frequency Furnace

Medium Frequency Furnace

2T Induction Melting Furnace

1T Induction Melting Furnace

500kg Induction Melting Furnace

250kg Induction Melting Furnace

Induction Melting Furnace

3 T Induction Melting Furnace

5T Induction Melting Furnace

1T One Belt Two Intermediate Frequency F

5T One Belt Two Intermediate Frequency F

3T One Belt Two Intermediate Frequency F

2T One Belt Two Intermediate Frequency F

5T Parallel Intermediate Frequency Furna

5T Intermediate Frequency Furnace

5T Series Intermediate Frequency Furnace

3T Series Intermediate Frequency Furnace

2T Series Intermediate Frequency Furnace

1T Series Intermediate Frequency Furnace

0.5T Series Intermediate Frequency Furna

0.25T Series Intermediate Frequency Furn

1T Parallel Intermediate Frequency Furna

2T Parallel Intermediate Frequency Furna

0.5T Parallel Intermediate Frequency Fur