Sales hot line ( 24 hours service):+86 13015583380

E-Mail: firstfurnace@gmail.com

whatsapp:+86 13015583380

Adress: Luoxin Industrial Park, Luoyang, HenanLarge diameter steel pipe quen

Piston rod quenching and tempe

Grinding rod quenching and tem

High frequency induction heate

Quenching equipment for machin

Round steel end heating furnac

Steel pipe heat treatment prod

Square steel quenching and tem

Sucker rod quenching and tempe

Thickened petroleum steel pipe

Round steel quenching and temp

Steel pipe quenching and tempe

Steel plate quenching and temp

Induction Hardening Machine&nb

Flywheel ring gear high freque

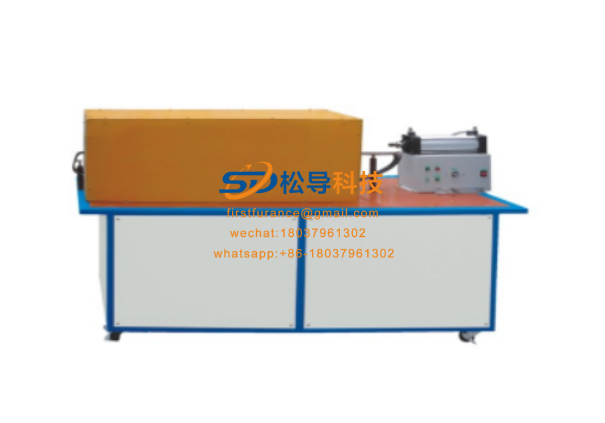

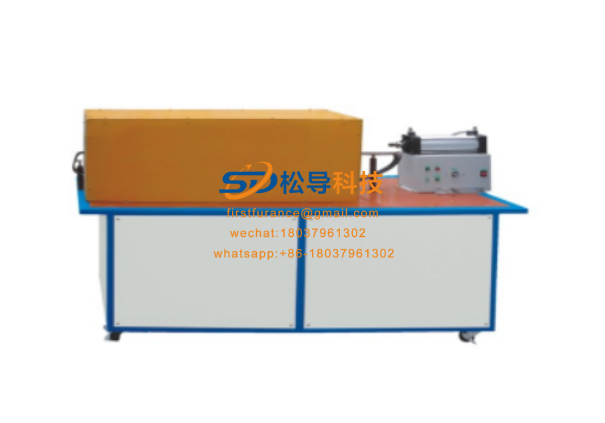

IGBT intermediate frequency bar heating furnace

New IGBT IF bar heating furnace technical characteristics:

1 , using IGBT devices, components, global sourcing

2 , using a combination of high-efficiency technology resonator

3 , a low inductance circuit arrangement

4 , the use of large-scale digital circuit

5 , a comprehensive and mature protection technical

novel IGBT intermediate bar heating furnace three advantages:

1 , a substantial energy saving, each heat a ton of steel, power 320 degrees. It saves 20%-30% of the power consumption of the thyristor .

2 , will not bring network side pollution, power supply transformers do not heat, substation compensation capacitors do not heat, do not interfere with other equipment work.

3. Reduce the capacity of the power supply transformer.

New IGBT IF bar heating furnace saving effect

300kW IGBT intermediate bar heating furnace: middle class 10 tons forging, saving per ton of 80-100 degrees, saving class 800-1000 degrees classes save electricity 560-700 yuan; month electricity savings of 2 million yuan; double shifts or three shifts of production, the monthly electricity savings of 4 Wan -6 million yuan. Equipment investment can be recovered in a few months.

Iron induction furnace

Aluminum melting furnace

Copper melting furnace

Small steel melting furnace

Small induction melting furnace

Induction iron furnace

3T intermediate frequency iron melting f

0.25T Intermediate Frequency Furnace

0.5T Intermediate Frequency Furnace

Medium Frequency Furnace

2T Induction Melting Furnace

1T Induction Melting Furnace

500kg Induction Melting Furnace

250kg Induction Melting Furnace

Induction Melting Furnace

3 T Induction Melting Furnace

5T Induction Melting Furnace

1T One Belt Two Intermediate Frequency F

5T One Belt Two Intermediate Frequency F

3T One Belt Two Intermediate Frequency F

2T One Belt Two Intermediate Frequency F

5T Parallel Intermediate Frequency Furna

5T Intermediate Frequency Furnace

5T Series Intermediate Frequency Furnace

3T Series Intermediate Frequency Furnace

2T Series Intermediate Frequency Furnace

1T Series Intermediate Frequency Furnace

0.5T Series Intermediate Frequency Furna

0.25T Series Intermediate Frequency Furn

1T Parallel Intermediate Frequency Furna

2T Parallel Intermediate Frequency Furna

0.5T Parallel Intermediate Frequency Fur