Sales hot line ( 24 hours service):+86 13015583380

E-Mail: firstfurnace@gmail.com

whatsapp:+86 13015583380

Adress: Luoxin Industrial Park, Luoyang, HenanLarge diameter steel pipe quen

Piston rod quenching and tempe

Grinding rod quenching and tem

High frequency induction heate

Quenching equipment for machin

Round steel end heating furnac

Steel pipe heat treatment prod

Square steel quenching and tem

Sucker rod quenching and tempe

Thickened petroleum steel pipe

Round steel quenching and temp

Steel pipe quenching and tempe

Steel plate quenching and temp

Induction Hardening Machine&nb

Flywheel ring gear high freque

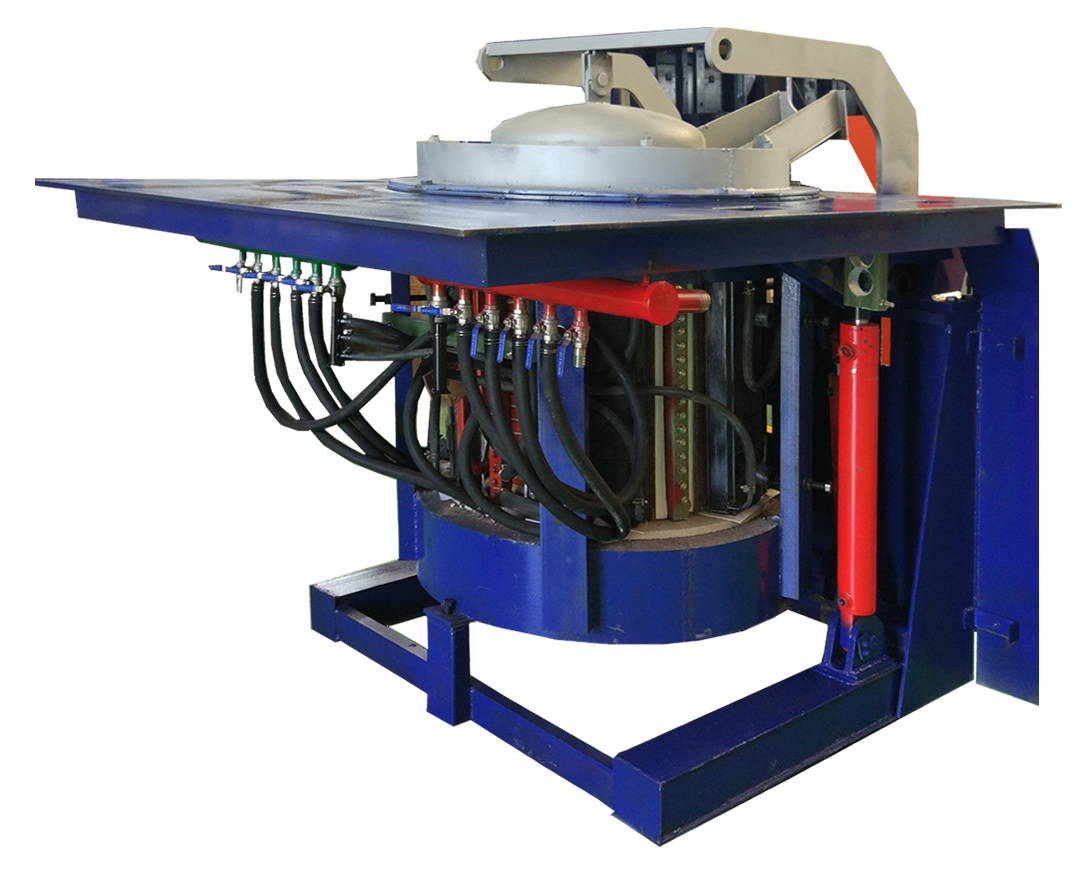

1 ton induction melting furnace with weighing system

1 ton induction melting furnace with weighing system

1 ton induction melting furnace with weighing system , with computer melting management system and weighing management system.

1. Equipment type:

This equipment is a 2017 new type of energy-saving electric furnace with a series inverter induction melting furnace , which has the characteristics of fast temperature increase, energy saving and consumption reduction, stable and reliable operation. The service life of the complete set of equipment is designed and manufactured according to 20 years. Each set of equipment includes: 800kw-1000kw series intermediate frequency power supply, 1T steel shell electric furnace, hydraulic pump station, water-cooled cable, cooling water distributor, crucible mold and installation materials.

2. Basic equipment composition

|

product name |

Specifications |

unit of measurement |

Quantity |

Note |

|

Series intermediate frequency power cabinet |

KGPS-1000 |

station |

1 |

|

|

Computer Melting Management System |

|

set |

1 |

|

|

Filter capacitor bank |

DCMJ1.2-1850S |

set |

1 |

|

|

Resonant capacitor bank |

RFM2.5-2000-0.5S |

set |

1 |

|

|

Water-cooled cable |

400mm2, 3.5-5m |

root |

2 |

|

|

Induction coil |

1T (700 * 1000) |

set |

1 |

|

|

Steel shell induction furnace body |

GW-1 |

set |

1 |

|

|

Tilting mechanism |

|

set |

1 |

|

|

Hydraulic station |

|

station |

1 |

|

|

Hydraulic operating table |

|

station |

1 |

|

Main technical parameters of 1 ton induction melting furnace equipment

|

A. Comprehensive parameters |

||

|

Serial number |

project |

Parameter requirements |

|

1 |

Equipment form |

IF melting furnace |

|

2 |

Equipment use |

For smelting cast iron, carbon steel, etc. |

|

3 |

Rated Capacity |

1T |

|

4 |

Maximum capacity |

1T + 30% |

|

5 |

Operating temperature |

1800 ℃ |

|

6 |

Smelting material |

cast iron |

|

7 |

Tilting method |

Steel case: hydraulic control |

|

8 |

Tilt angle |

95 degrees |

|

9 |

Working noise |

<85dB |

|

10 |

Furnace structure |

Steel shell |

|

11 |

Outlet method |

Side exit |

|

12 |

Melting rate |

1.1T / h |

|

13 |

Oven temperature |

1700 ℃ + 20 ℃ |

|

14 |

Melting power consumption |

≤580kW.h / t |

|

B. Electrical parameters: |

||

|

Serial number |

project |

parameter |

|

1 |

Power |

800KW / three-phase, six-phase 1T |

|

2 |

Number of rectified terms |

6-pulse, 12-pulse |

|

3 |

Inverter |

SCR rectifier series |

|

4 |

Rated frequency |

500Hz |

|

5 |

Line voltage |

380v, 660v, 800v |

|

6 |

IF voltage |

3000V |

|

7 |

Startup success rate |

100% |

|

8 |

Power factor |

Greater than 0.98 |

|

C. Parameters of heat exchange cooling water system |

||

|

Serial number |

project |

parameter |

|

1 |

Inlet water pressure |

0.2-0.4MPa |

|

2 |

Inlet water temperature |

5-35 ℃ |

|

3 |

Water temperature |

<55 ℃ |

Iron induction furnace

Aluminum melting furnace

Copper melting furnace

Small steel melting furnace

Small induction melting furnace

Induction iron furnace

3T intermediate frequency iron melting f

0.25T Intermediate Frequency Furnace

0.5T Intermediate Frequency Furnace

Medium Frequency Furnace

2T Induction Melting Furnace

1T Induction Melting Furnace

500kg Induction Melting Furnace

250kg Induction Melting Furnace

Induction Melting Furnace

3 T Induction Melting Furnace

5T Induction Melting Furnace

1T One Belt Two Intermediate Frequency F

5T One Belt Two Intermediate Frequency F

3T One Belt Two Intermediate Frequency F

2T One Belt Two Intermediate Frequency F

5T Parallel Intermediate Frequency Furna

5T Intermediate Frequency Furnace

5T Series Intermediate Frequency Furnace

3T Series Intermediate Frequency Furnace

2T Series Intermediate Frequency Furnace

1T Series Intermediate Frequency Furnace

0.5T Series Intermediate Frequency Furna

0.25T Series Intermediate Frequency Furn

1T Parallel Intermediate Frequency Furna

2T Parallel Intermediate Frequency Furna

0.5T Parallel Intermediate Frequency Fur