Sales hot line ( 24 hours service): 18037961302

E-Mail: firstfurnace@gmail.com

whatsapp:+8618037961302

Adress: Luoxin Industrial Park, Luoyang, HenanLarge diameter steel pipe quen

Piston rod quenching and tempe

Grinding rod quenching and tem

High frequency induction heate

Quenching equipment for machin

Round steel end heating furnac

Steel pipe heat treatment prod

Square steel quenching and tem

Sucker rod quenching and tempe

Thickened petroleum steel pipe

Round steel quenching and temp

Steel pipe quenching and tempe

Steel plate quenching and temp

Induction Hardening Machine&nb

Flywheel ring gear high freque

medium frequency induction furnace transformer technical requirements

1. Model: ZS-2450/10 (12-pulse 6-phase bridge full-wave rectifier transformer with phase shift-7.5 ° )

2. Rated capacity: 2450KVA , each group of harmonic currents on the low-voltage side is as follows:

(5 times 17.5% , 7 times 11% , 11 times 4.5% , 13 times 2.9% , 17 times 1.5% , 19 times 1.0% , 23 times 0.9% , 25 times 0.8%)

1. Voltage ratio: 10KV / 0.575KV no-load voltage regulation 10KV +/- 2.5%

2. Rated short-circuit impedance: 5.5 - 7.5% , Y , Δ winding rated impedance is equal The neutral point of the Y -connection is not taken out and is not grounded.

1. Link group label: Dy11 , DD12 ( Δ / Y , Δ )

Primary phase shift -7. 5 ° (-7.5 ° phase shift and provide a vector) phase shift error of the phase angle should not exceed 0.35 °

1. Y , Δ winding voltage difference is as small as possible, the maximum can not exceed 0.28%

2. Number of phases: 3- phase input 6- phase output

3. Rated frequency: 50Hz

4. Cooling method: ONAN cooling medium: 25# transformer oil

5. Maximum indoor working temperature: 45 °C

6. Oil surface temperature rise: less than 50 K winding temperature rise: less than 60K

7. Insulation level:Primary power frequency withstand voltage: 45KV primary side full-wave impulse withstand voltage: 95KV,Secondary power frequency withstand voltage, secondary full wave shock withstand voltage: refer to national standard The secondary must bear 3300V to the ground at any time

1. Electrostatic shield protection between primary and secondary windings

2. The inlet and outlet wires are fixed to the top cover of the transformer with a sleeve

16. The relative position of the oil pillow and the high and low pressure outlets . ( Low pressure side close to the VIP cabinet )

1. Accessories: Should be equipped with oil filling valve, gas relay, oil level indication, thermometer ( disc type, can be set manually ) , discharge valve, pressure relief valve, marked signage, grounding end, lifting ring around, use no Load-regulating switch with locking device.

2. The heat sink should be placed symmetrically, and the butterfly valve should be installed at the joint between the heat sink and the transformer body.

3. Load loss:

4. Dimensions: length X width X height

5. Installation gauge: gauge distance 1070X1070 square, channel ring

6. There is a junction box next to the transformer, which has terminals, one side connected to the thermometer, gas relay and other signals, and the other side connected to the high voltage switch cabinet.

7. Reference Standards: ANSI, IEC, GB 6451 , GB1094 and JB/T8636-1997 Current Standards for Power Converters.

8. Technical Information:

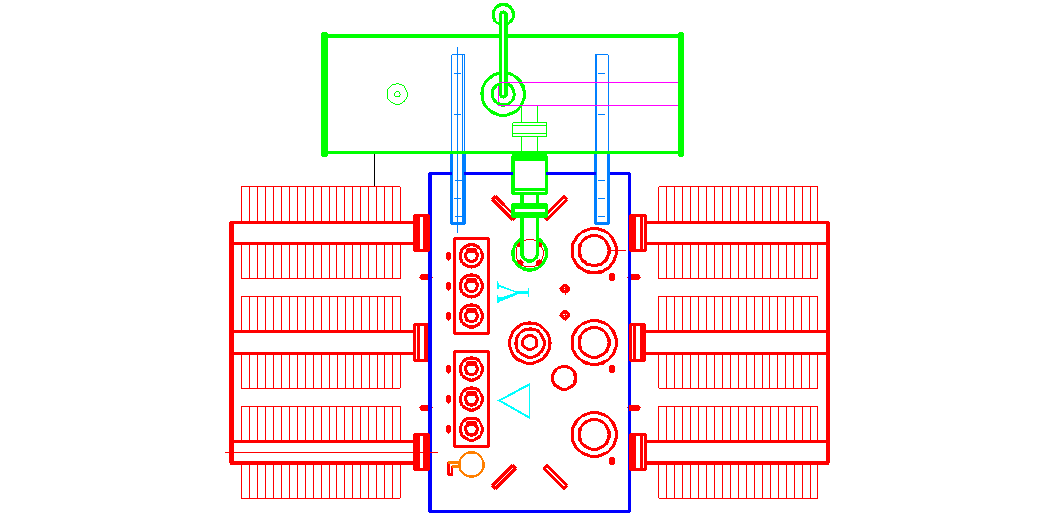

a)Transformer assembly drawing

b)After the design of the transformer outline drawing ( AUTOCAD ) is completed, EMAIL will be sent to our company, and then confirmed and put into production.

c)Transformers, bushings, general components, oil conservators, gas relays, temperature controllers, radiators, unloaded tap-changers, pressure relief valves, etc.

d) Gas relay factory test report

e) Product test report

f) Product certification

g) The above technical materials are shipped randomly, and a copy of the above technical information is sent to Yingda Industrial ( Shanghai ) Co., Ltd. for archival purposes.

Service: If the transformer oil storage cabinet and radiator are shipped in bulk, the manufacturer dispatches relevant technicians to the user's work site to perform on-site installation and commissioning of the transformer (the manufacturer is responsible for installing the oil conservator, gas relay, temperature controller, radiator). And on-site refueling, etc.).

Iron induction furnace

Aluminum melting furnace

Copper melting furnace

Small steel melting furnace

Small induction melting furnace

Induction iron furnace

3T intermediate frequency iron melting f

0.25T Intermediate Frequency Furnace

0.5T Intermediate Frequency Furnace

Medium Frequency Furnace

2T Induction Melting Furnace

1T Induction Melting Furnace

500kg Induction Melting Furnace

250kg Induction Melting Furnace

Induction Melting Furnace

3 T Induction Melting Furnace

5T Induction Melting Furnace

1T One Belt Two Intermediate Frequency F

5T One Belt Two Intermediate Frequency F

3T One Belt Two Intermediate Frequency F

2T One Belt Two Intermediate Frequency F

5T Parallel Intermediate Frequency Furna

5T Intermediate Frequency Furnace

5T Series Intermediate Frequency Furnace

3T Series Intermediate Frequency Furnace

2T Series Intermediate Frequency Furnace

1T Series Intermediate Frequency Furnace

0.5T Series Intermediate Frequency Furna

0.25T Series Intermediate Frequency Furn

1T Parallel Intermediate Frequency Furna

2T Parallel Intermediate Frequency Furna

0.5T Parallel Intermediate Frequency Fur