Sales hot line ( 24 hours service): 18037961302

E-Mail: firstfurnace@gmail.com

whatsapp:+8618037961302

Adress: Luoxin Industrial Park, Luoyang, HenanLarge diameter steel pipe quen

Piston rod quenching and tempe

Grinding rod quenching and tem

High frequency induction heate

Quenching equipment for machin

Round steel end heating furnac

Steel pipe heat treatment prod

Square steel quenching and tem

Sucker rod quenching and tempe

Thickened petroleum steel pipe

Round steel quenching and temp

Steel pipe quenching and tempe

Steel plate quenching and temp

Induction Hardening Machine&nb

Flywheel ring gear high freque

Tubing end thickening technical indicators

1, the outer end of the thick line pipe use environment

1 indoor installation, equipment grounding is good, the color of the grounding wire is obviously different from the control line (the color of the grounding wire is yellow), the cross-sectional area is > 4mm2 , and the grounding resistance is not more than 4 Ω;

2 The altitude should not exceed 1000 meters, otherwise the rated value should be reduced;

3 ambient temperature does not exceed +40 <C, not lower than -10 <C;

4 air relative humidity is not more than 85% ;

5 no severe vibration, no conductive dust, no corrosive gases and explosive gases;

6 installation inclination is not more than 5 degrees;

7 Installed in a well ventilated area.

2 , the tubing end thickening production line grid requirements

1 ) 180KW medium frequency power distribution capacity is not less than 225KVA . 220KW medium frequency power distribution capacity is not less than 275KVA

2 ) The grid voltage should be sinusoidal and the harmonic distortion is no more than 5% .

3 ) The imbalance between three-phase voltages should be less than \ 5%

4 ) The input voltage of the grid is 380V of line voltage AC , and the continuous fluctuation range of the grid voltage does not exceed

\ 10% , the grid frequency does not change by more than \ 2% (ie should be between 49~51HZ ).

5 ) The 180KW and 220KW intermediate frequency power supply cable adopts three-phase four-wire system. The incoming cable specification is copper core 240mm2 or 120mm2 〜 2 .

3. Main technical indicators of water cooling system

The intermediate frequency induction heating power supply , water-cooled cable, capacitor cabinet, heating furnace body, etc. are cooled by two FL-500 wind - water exchangers.

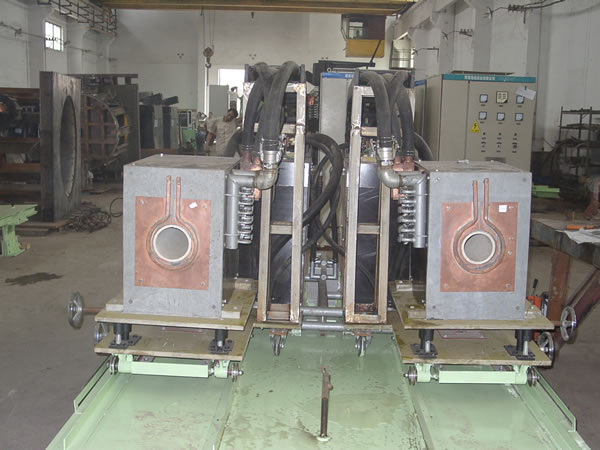

4 , the main technical indicators of the sensor drive system

1 ) Sensor specifications:

No. 1 sensor: inner diameter ф 100mm , suitable for typical tubing specifications ф 60.3~ ф 73.03mm .

No. 2 sensor: inner diameter ф 120mm , suitable for typical tubing specifications ф 88.9mm

2 ) Sensor adjustment:

X- axis direction (left and right): \ 10mm

Z- axis direction (upper and lower): \ 25mm

3) Sensor length: 500mm-650mm

Tubing end thickening technical indicators

Iron induction furnace

Aluminum melting furnace

Copper melting furnace

Small steel melting furnace

Small induction melting furnace

Induction iron furnace

3T intermediate frequency iron melting f

0.25T Intermediate Frequency Furnace

0.5T Intermediate Frequency Furnace

Medium Frequency Furnace

2T Induction Melting Furnace

1T Induction Melting Furnace

500kg Induction Melting Furnace

250kg Induction Melting Furnace

Induction Melting Furnace

3 T Induction Melting Furnace

5T Induction Melting Furnace

1T One Belt Two Intermediate Frequency F

5T One Belt Two Intermediate Frequency F

3T One Belt Two Intermediate Frequency F

2T One Belt Two Intermediate Frequency F

5T Parallel Intermediate Frequency Furna

5T Intermediate Frequency Furnace

5T Series Intermediate Frequency Furnace

3T Series Intermediate Frequency Furnace

2T Series Intermediate Frequency Furnace

1T Series Intermediate Frequency Furnace

0.5T Series Intermediate Frequency Furna

0.25T Series Intermediate Frequency Furn

1T Parallel Intermediate Frequency Furna

2T Parallel Intermediate Frequency Furna

0.5T Parallel Intermediate Frequency Fur