Sales hot line ( 24 hours service): 18037961302

E-Mail: firstfurnace@gmail.com

whatsapp:+8618037961302

Adress: Luoxin Industrial Park, Luoyang, HenanLarge diameter steel pipe quen

Piston rod quenching and tempe

Grinding rod quenching and tem

High frequency induction heate

Quenching equipment for machin

Round steel end heating furnac

Steel pipe heat treatment prod

Square steel quenching and tem

Sucker rod quenching and tempe

Thickened petroleum steel pipe

Round steel quenching and temp

Steel pipe quenching and tempe

Steel plate quenching and temp

Induction Hardening Machine&nb

Flywheel ring gear high freque

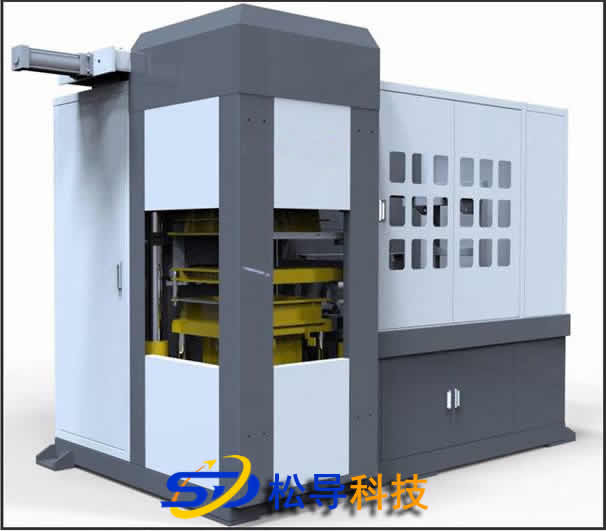

Casting molding machine operating procedures

The foundry molding machine is widely used in industrial production. How to safely operate the foundry molding machine is a concern of every producer. The safety operation procedures of the molding machine are introduced below.

Modeling machine operating procedures:

1. Obey the general operating procedures of the molding machine and the core making machine.

2. When the molding machine is demolished, the ejector rod must be raised smoothly and synchronously. Otherwise, the maintenance personnel should be notified to repair it.

3. The molding machine pressure is real-time, and the sand-reducing beam turret should be rotated smoothly. Do not operate too hard and produce impact.

4. The operator must pay attention to whether the mold is good before and after production, and whether the outer mold and the positioning pin of the core mold are matched.

5. The staff who operate the molding machine should concentrate on thinking.

6. After the molding machine is completed, the mold should be lifted to the specified pouring point (line) according to the process regulations. Place it neatly and lock it with a pressure iron or clip. Miscellaneous items must be marked.

7, the molding machine sand box is not allowed to stack too high, generally not more than two meters, the tools used must be stacked neatly to prevent accidents.

8. When using the blowtorch, pay attention to safety and prevent fire. The running light must be a low-voltage bulb below 36V, and disable the high-voltage bulb above 220V.

9. When using the driving machine, check whether the spreader is good. When lifting, the hook should be fastened and the chain should be straightened. It is not allowed to slant and overload.

10. It is strictly forbidden to modify the mold under the lifting sand box. When the large sand box is unpacked, it must be replaced with a square object when turning over the cushion box.

11. The sand box used in the molding machine must be firm, and the hand should be complete without cracks and bending.

Iron induction furnace

Aluminum melting furnace

Copper melting furnace

Small steel melting furnace

Small induction melting furnace

Induction iron furnace

3T intermediate frequency iron melting f

0.25T Intermediate Frequency Furnace

0.5T Intermediate Frequency Furnace

Medium Frequency Furnace

2T Induction Melting Furnace

1T Induction Melting Furnace

500kg Induction Melting Furnace

250kg Induction Melting Furnace

Induction Melting Furnace

3 T Induction Melting Furnace

5T Induction Melting Furnace

1T One Belt Two Intermediate Frequency F

5T One Belt Two Intermediate Frequency F

3T One Belt Two Intermediate Frequency F

2T One Belt Two Intermediate Frequency F

5T Parallel Intermediate Frequency Furna

5T Intermediate Frequency Furnace

5T Series Intermediate Frequency Furnace

3T Series Intermediate Frequency Furnace

2T Series Intermediate Frequency Furnace

1T Series Intermediate Frequency Furnace

0.5T Series Intermediate Frequency Furna

0.25T Series Intermediate Frequency Furn

1T Parallel Intermediate Frequency Furna

2T Parallel Intermediate Frequency Furna

0.5T Parallel Intermediate Frequency Fur