Sales hot line ( 24 hours service): 18037961302

E-Mail: firstfurnace@gmail.com

whatsapp:+8618037961302

Adress: Luoxin Industrial Park, Luoyang, HenanLarge diameter steel pipe quen

Piston rod quenching and tempe

Grinding rod quenching and tem

High frequency induction heate

Quenching equipment for machin

Round steel end heating furnac

Steel pipe heat treatment prod

Square steel quenching and tem

Sucker rod quenching and tempe

Thickened petroleum steel pipe

Round steel quenching and temp

Steel pipe quenching and tempe

Steel plate quenching and temp

Induction Hardening Machine&nb

Flywheel ring gear high freque

There is a good method for calculating the load circuit of the intermediate frequency electric furnace.

Induction melting furnace principle : There is a good method for calculating the load circuit of medium frequency electric furnace

(1) Frequency electric load circuit Q value, based on experience, taking Q smelting furnace 12, i.e., Q = 12.

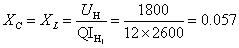

( 2 ) The impedance of the intermediate frequency electric furnace load circuit load tank resonance is

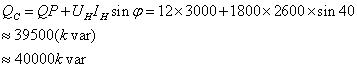

( 3 ) Large capacity Qc of medium frequency electric furnace capacitor

If you choose a capacitor with RFM1.6-2000-0.5s specifications, you need about 20 units.

4 Medium frequency electric furnace current transmission channel material selection

The current carrying capacity of copper material has a great relationship with the current frequency. Generally speaking, the higher the frequency, the smaller the current carrying capacity of the copper row, and the water cooling can increase the current carrying capacity per unit section. The following empirical values are for reference only:

The power frequency incoming copper cable and copper discharge current are selected according to 2~3A/mm 2 ; the DC copper discharge current is selected according to 1.8 - 2.5A/mm 2 ; the intermediate frequency copper cable and copper discharge current ( related to frequency ) are 1.5. ~2.0A/mm 2 choice; water-cooled copper row is selected by 4~8A/mm 2 ; water-cooled cable is selected by 8~15A/mm 2 ; sensor copper tube is selected by <60A/mm 2 .

Iron induction furnace

Aluminum melting furnace

Copper melting furnace

Small steel melting furnace

Small induction melting furnace

Induction iron furnace

3T intermediate frequency iron melting f

0.25T Intermediate Frequency Furnace

0.5T Intermediate Frequency Furnace

Medium Frequency Furnace

2T Induction Melting Furnace

1T Induction Melting Furnace

500kg Induction Melting Furnace

250kg Induction Melting Furnace

Induction Melting Furnace

3 T Induction Melting Furnace

5T Induction Melting Furnace

1T One Belt Two Intermediate Frequency F

5T One Belt Two Intermediate Frequency F

3T One Belt Two Intermediate Frequency F

2T One Belt Two Intermediate Frequency F

5T Parallel Intermediate Frequency Furna

5T Intermediate Frequency Furnace

5T Series Intermediate Frequency Furnace

3T Series Intermediate Frequency Furnace

2T Series Intermediate Frequency Furnace

1T Series Intermediate Frequency Furnace

0.5T Series Intermediate Frequency Furna

0.25T Series Intermediate Frequency Furn

1T Parallel Intermediate Frequency Furna

2T Parallel Intermediate Frequency Furna

0.5T Parallel Intermediate Frequency Fur