Sales hot line ( 24 hours service): 18037961302

E-Mail: firstfurnace@gmail.com

whatsapp:+8618037961302

Adress: Luoxin Industrial Park, Luoyang, HenanLarge diameter steel pipe quen

Piston rod quenching and tempe

Grinding rod quenching and tem

High frequency induction heate

Quenching equipment for machin

Round steel end heating furnac

Steel pipe heat treatment prod

Square steel quenching and tem

Sucker rod quenching and tempe

Thickened petroleum steel pipe

Round steel quenching and temp

Steel pipe quenching and tempe

Steel plate quenching and temp

Induction Hardening Machine&nb

Flywheel ring gear high freque

Resistance matching of heating induction melting furnace

Induction melting furnace cold state startability is poor, heating power is low, is the main problem of the current intermediate frequency power supply heating device, in the future to improve the cold impedance matching, improve the heating power, analyze the cause of the initial heating power and its impact on the intermediate frequency power supply The hazard of the medium frequency induction device from the low temperature to high temperature heating process and the relationship between the load impedance and the workpiece resistance and resonant capacitance.

Induction melting furnace start-up circuit

The difficulty of the thyristor intermediate frequency power supply is starting, that is, how to make the frequency tracking circuit obtain the correct channel resonance frequency signal before the power supply works normally. The traditional medium frequency power supply adopts pre-magnetization, pre-charging mode, complicated circuit and low starting success rate (a new thyristor filter starting circuit) system has fundamental wave delay, so the dynamics is poor. Some 400Hz intermediate frequency power supplies are widely used in various fields. The constant voltage constant frequency PWM inverter circuit is the core of the whole intermediate frequency power supply system, which plays a decisive role for the power supply of the entire intermediate frequency power supply. However, a single waveform control technique often does not yield high quality output voltage waveforms.

In general, as the load changes, when the nonlinearity of the load is strong, the total distortion rate of the voltage is high, and it is difficult for the system to have a composite stable voltage output, which is difficult to meet when the demand is high.

Iron induction furnace

Aluminum melting furnace

Copper melting furnace

Small steel melting furnace

Small induction melting furnace

Induction iron furnace

3T intermediate frequency iron melting f

0.25T Intermediate Frequency Furnace

0.5T Intermediate Frequency Furnace

Medium Frequency Furnace

2T Induction Melting Furnace

1T Induction Melting Furnace

500kg Induction Melting Furnace

250kg Induction Melting Furnace

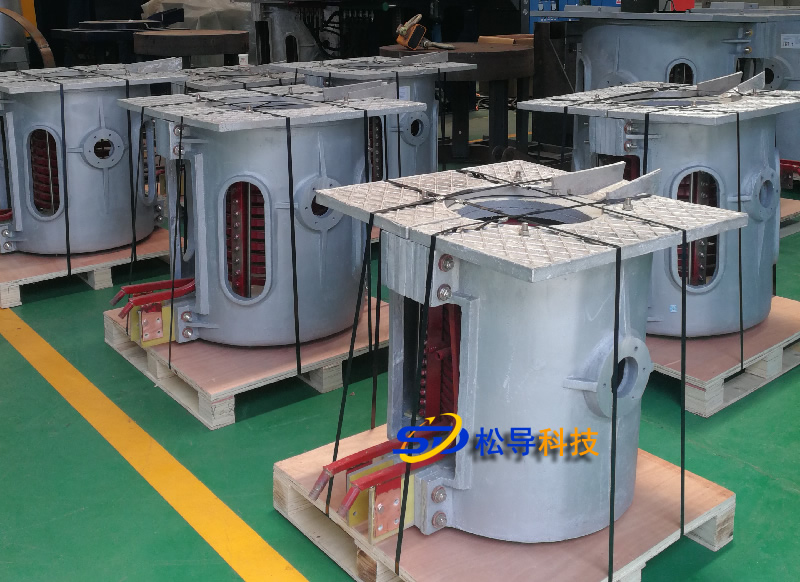

Induction Melting Furnace

3 T Induction Melting Furnace

5T Induction Melting Furnace

1T One Belt Two Intermediate Frequency F

5T One Belt Two Intermediate Frequency F

3T One Belt Two Intermediate Frequency F

2T One Belt Two Intermediate Frequency F

5T Parallel Intermediate Frequency Furna

5T Intermediate Frequency Furnace

5T Series Intermediate Frequency Furnace

3T Series Intermediate Frequency Furnace

2T Series Intermediate Frequency Furnace

1T Series Intermediate Frequency Furnace

0.5T Series Intermediate Frequency Furna

0.25T Series Intermediate Frequency Furn

1T Parallel Intermediate Frequency Furna

2T Parallel Intermediate Frequency Furna

0.5T Parallel Intermediate Frequency Fur