Sales hot line ( 24 hours service): 18037961302

E-Mail: firstfurnace@gmail.com

whatsapp:+8618037961302

Adress: Luoxin Industrial Park, Luoyang, HenanLarge diameter steel pipe quen

Piston rod quenching and tempe

Grinding rod quenching and tem

High frequency induction heate

Quenching equipment for machin

Round steel end heating furnac

Steel pipe heat treatment prod

Square steel quenching and tem

Sucker rod quenching and tempe

Thickened petroleum steel pipe

Round steel quenching and temp

Steel pipe quenching and tempe

Steel plate quenching and temp

Induction Hardening Machine&nb

Flywheel ring gear high freque

Induction melting furnace to control the temperature of a few kinds of ways?

(1) The induction melting furnace controls the temperature so that the temperature of the molten iron is always maintained at the temperature of the tapping.

(2) as far as possible at a low melting temperature, and then pour the liquid iron overheating.

The second method of controlling the temperature of the molten iron has the following advantages.

A. The furnace lining that can keep the quartz sand sintered is at a low temperature, thereby increasing the furnace age.

B. It is better than the lower temperature of the molten iron, and its corresponding viscosity is higher, so the electromagnetic stirring action of the solution and the height of the molten metal dome can be appropriately suppressed, and the wear of the circumferential pressure of the lining is reduced.

(3) Increasing the amount of charge added each time is beneficial to improving the load power state of the furnace, increasing the temperature of the solution and increasing the working efficiency of the furnace.

(4) Due to the reduced number of charging times, the number of opening and closing of the furnace cover is reduced, the heat loss of the furnace is reduced, and the working conditions are improved.

3 , melting temperature

When melting iron in the induction melting furnace, the melting temperature of the material is required to ensure that performance is obtained and an important factor.

Maximum heating temperature and tapping temperature of various grades

|

|

Maximum heating temperature |

Iron temperature |

|

HT200 |

1490-1510 |

About 1500 |

|

HT250 |

1500-1510 |

1480-1510 |

|

HT300 |

1500-1510 |

1480-1510 |

4, residual liquid melting method

The circuit utilization coefficient of the residual liquid melting method is the largest, that is, the melting efficiency of the furnace is the highest, the unit consumption is the smallest, and the temperature fluctuation of the molten iron is also the smallest.

The residual liquid melting method is actually a kind of continuous melting, and it is preferable to use one third of the residual liquid for melting.

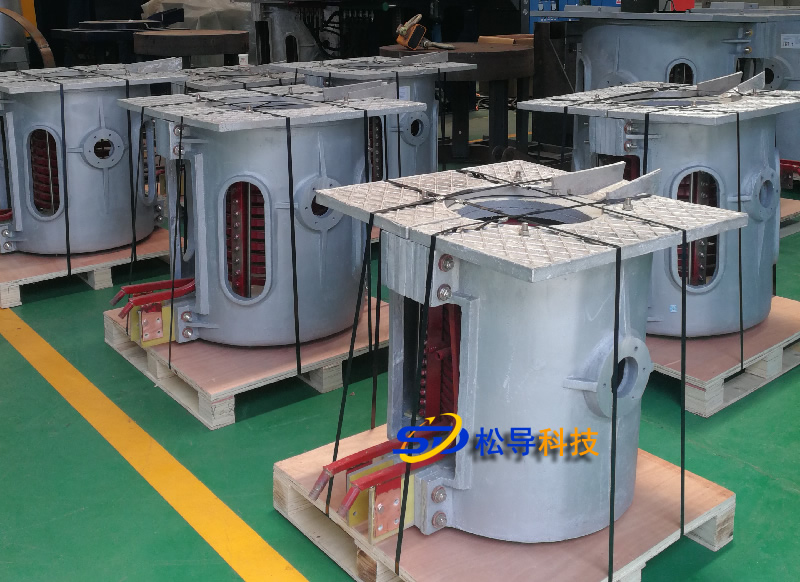

Iron induction furnace

Aluminum melting furnace

Copper melting furnace

Small steel melting furnace

Small induction melting furnace

Induction iron furnace

3T intermediate frequency iron melting f

0.25T Intermediate Frequency Furnace

0.5T Intermediate Frequency Furnace

Medium Frequency Furnace

2T Induction Melting Furnace

1T Induction Melting Furnace

500kg Induction Melting Furnace

250kg Induction Melting Furnace

Induction Melting Furnace

3 T Induction Melting Furnace

5T Induction Melting Furnace

1T One Belt Two Intermediate Frequency F

5T One Belt Two Intermediate Frequency F

3T One Belt Two Intermediate Frequency F

2T One Belt Two Intermediate Frequency F

5T Parallel Intermediate Frequency Furna

5T Intermediate Frequency Furnace

5T Series Intermediate Frequency Furnace

3T Series Intermediate Frequency Furnace

2T Series Intermediate Frequency Furnace

1T Series Intermediate Frequency Furnace

0.5T Series Intermediate Frequency Furna

0.25T Series Intermediate Frequency Furn

1T Parallel Intermediate Frequency Furna

2T Parallel Intermediate Frequency Furna

0.5T Parallel Intermediate Frequency Fur